Assem

bl

y and

Setup

Assembly and Setup

NOTE

• Throughout the instructions,

ref-

erence numbers appear in paren-

theses following the part name.

These numbers correspond with

reference numbers on the

draw-

ings

in

this section and the Parts

List

section.

• The assembly and setup instruc-

tions for the "Table and Table

Support Assembly" are written

primarily for Mark V Models

500

and

510.

If your system is a Mark

II,

follow the instructions speci-

fied for Model

500;

for a Mark

VII,

follow the instructions specified

for Model

500

for mounting the

table supports and Model

510

for

mounting the table posts.

Before any operations can

be

per-

formed, you must assemble some

parts, set them up properly, and align

them on the Mark

V.

Your safety and

proper use of the Lathe Duplicator de-

pend on your following the Assembly

and Setup instructions exactly, espe-

cially those pertaining to your

specific

Mark V Model. If you're unsure as

to which Model Mark V you own, refer

to the NOTE on page

2.

Tools Supplied: 1/4",5/16" and 7/64"

Allen wrenches.

Tools and Supplies Required: 5/32"

standard Mark V Allen wrench, 9/16"

socket and socket wrench (or 9/16"

wrench), accurate combination square,

straightedge, mineral spirits and

flooror

furniture paste wax.

Mark V Setup

Set up the Mark V

in

the lathe mode

according

to

the following procedures:

WARNING

Turn off and unplug the Mark V

before

you

begin

any

setup

procedures.

The following procedures assume

that the worktable has been

re-

moved,

that

there

is

nothing

mounted

on

any spindles of the

machine and that all alignment

and adjustment procedures spec-

ified

in

the Mark V Owners Manual

have been completed_

1_

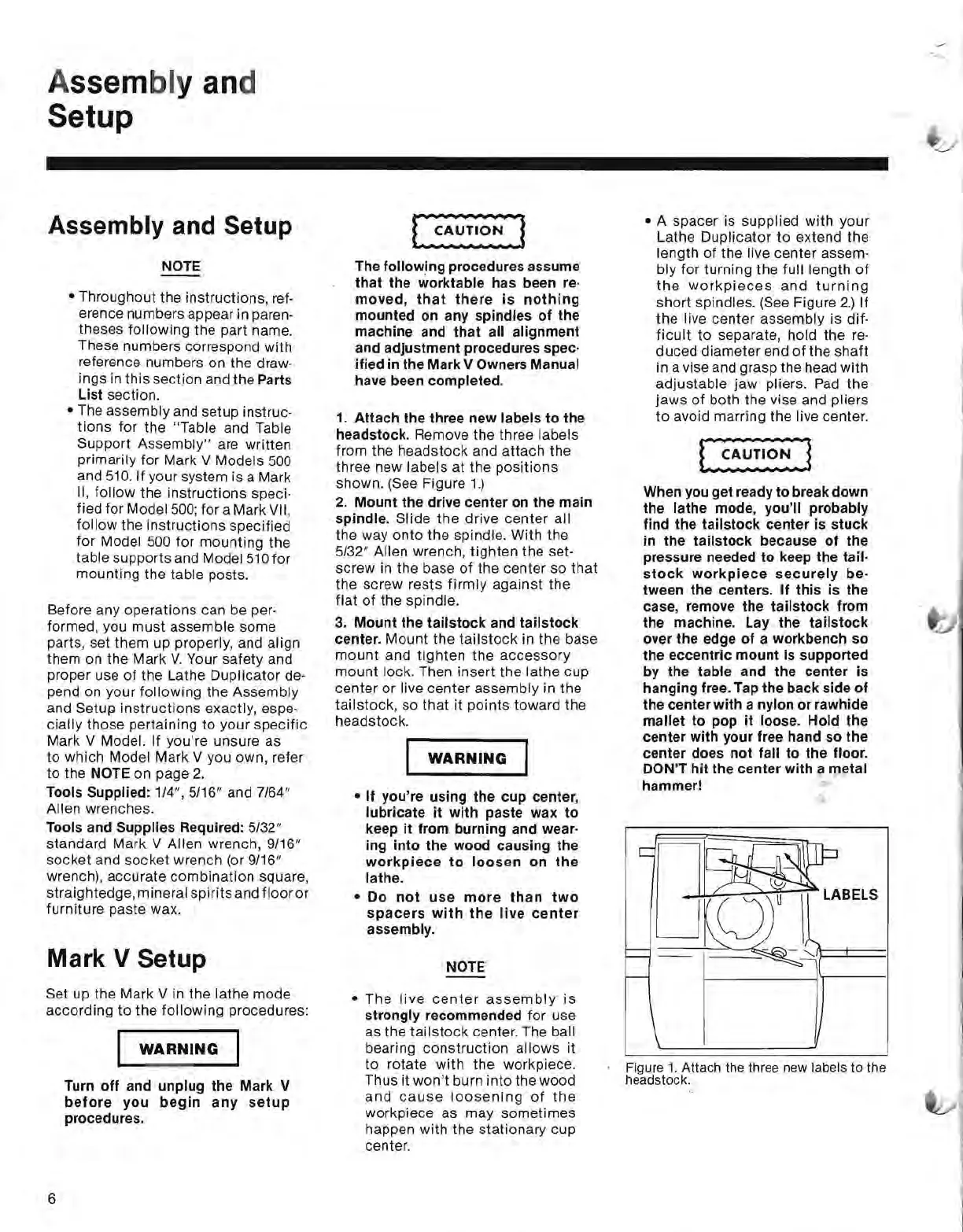

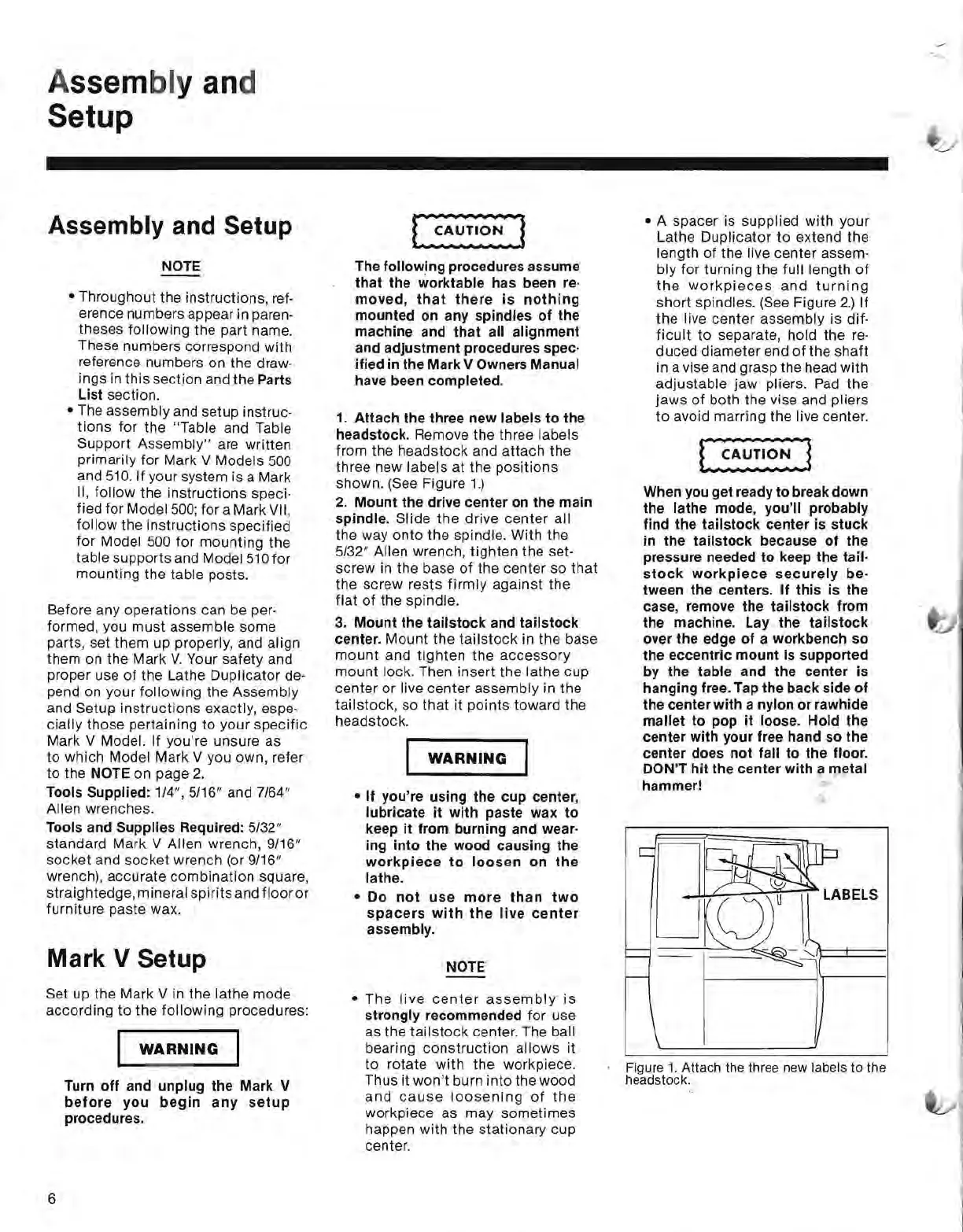

Attach the three new labels to the

headstock.

Remove the three labels

from the headstock and attach the

three new labels at the positions

shown.

(See Figure

1.)

2.

Mount the drive center

on

the main

spindle.

Slide

the

drive center all

the way onto the spindle. With the

5/32" Allen wrench, tighten the set-

screw in the base

of

the center so

that

the screw rests

firmly

against the

flat

of

the spindle.

3_

Mount the tailstock and tailstock

center_

Mount the

tailstock

in the base

mount

and

tighten

the

accessory

mount lock. Then insert the lathe cup

center or live center assembly in the

tailstock, so

that

it points toward the

headstock.

WARNING

• If you're using the cup center,

lubricate it with paste wax to

keep it from burning and wear-

ing into the wood causing the

workpiece

to

loosen

on

the

lathe_

• Do

not

use

more

than

two

spacers

with

the

live

center

assembly_

NOTE

• The

live

center

assembly

is

strongly recommended for use

as the

tailstock

center. The ball

bearing construction allows it

to

rotate with the workpiece.

Thus it

won't

burn into the wood

and

cause

loosening

of

the

workpiece as may sometimes

happen with the stationary cup

center.

• A spacer is supplied with your

Lathe Duplicator

to

extend the

length

of

the live center assem-

bly for turning the full length

of

the

workpieces

and

turning

short spindles.

(See

Figure

2.)

If

the live center assembly is dif-

ficult

to separate, hold the

re-

duced diameter end

of

the shaft

in a vise and grasp the head with

adjustable jaw pliers.

Pad

the

jaws

of

both the vise and pliers

to

avoid marring the live center.

When

you

get ready to break down

the lathe mode, you'll probably

find the tailstock center

is

stuck

in

the tailstock because of the

pressure needed to keep the tail-

stock

workpiece

securely

be-

tween the centers_ If this is the

case, remove the tailstock from

the machine_ Lay the tailstock

over the edge of a workbench so

the eccentric mount

is

supported

by the table and the center is

hanging

free_

Tap the back side of

the center with a nylon or rawhide

mallet to pop it

loose_

Hold the

center with your free hand so the

center does not fall to the

floor_

DON'T hit the center with a metal

hammer!

£....,.~~'f.--;;-

LABELS

Figure

1.

Attach

the three new labels

to

the

headstock.

6

Loading...

Loading...