Page 35

845180 SHOPSMITH MARK V

4. When you've lubricated both Sheaves,

replace the Logo Cover and Belt Cover.

Attach the Sanding Disc to the Main

Spindle and while rotating the Disc

(clockwise) turn the Speed Control Dial

to “Slow” speed. Plug in the MARK V

and turn it on. Run the machine com-

pletely through the speed range several

times to help spread out the oil.

LUBRICATING THE LOCKS

Every 50 hours of running time or at least once

a year, apply a dry lubricant product to the

threads of the Headstock Lock.

1. First inspect the Threaded Rods of the

Headstock Lock (found inside the Head-

stock) and the Carriage Lock (under-

neath the Carriage). Brush off or wipe off

any foreign materials.

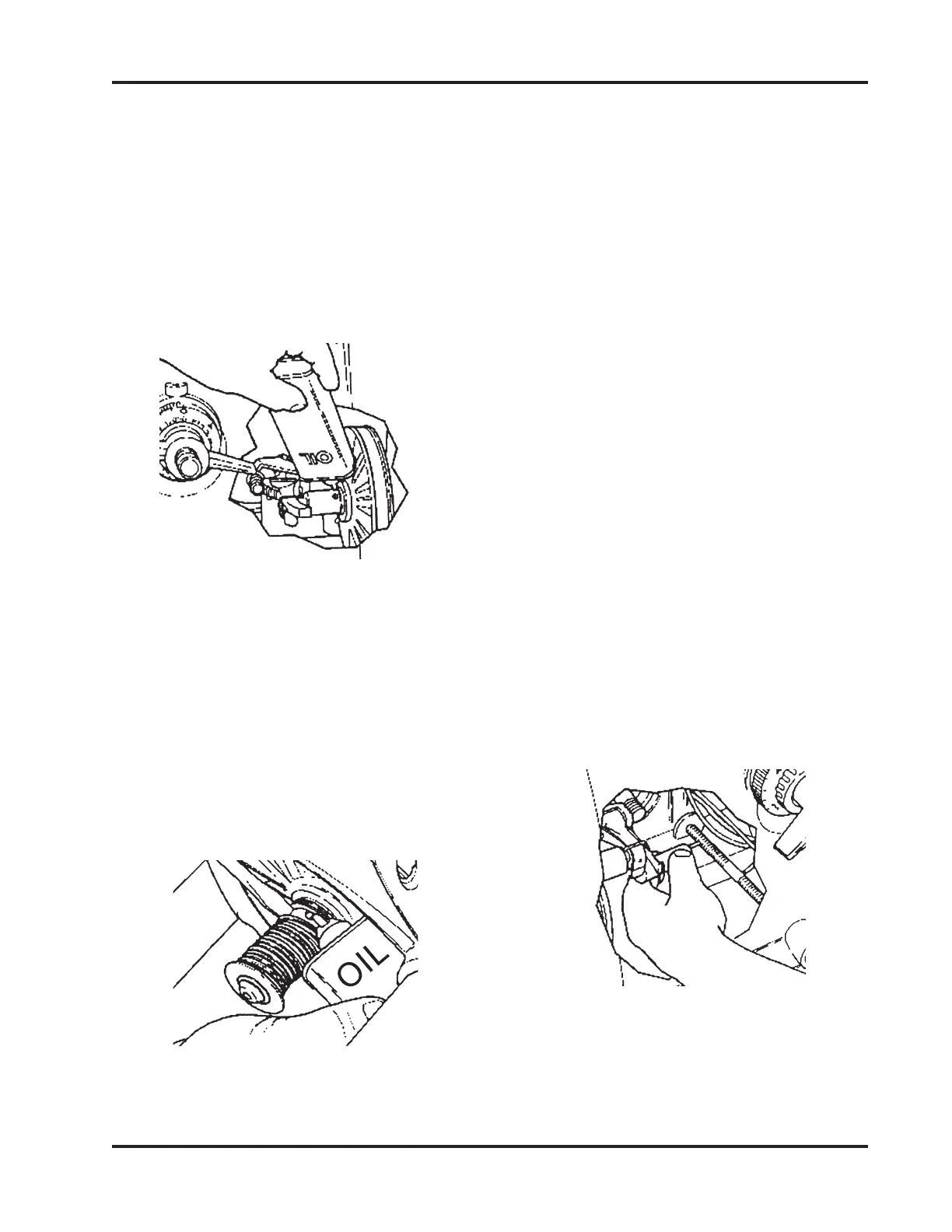

2. To lubricate the Headstock Lock, loosen

the Lock as far as possible. Then reach

inside the Access Hole opening and ap-

ply a small amount of powdered graph-

ite to the points where the Threaded Rod

screws into the Wedge Locks, as illus-

trated in Figure 115.

Figure 115

3. Replace the Logo Cover and secure the

Headstock Lock.

only time the MARK V should be turned

off at other than “Slow” speed.

2. Oil the Upper Control Sheave first. While

looking through the Access Hole open-

ing, turn the Main Spindle by hand (clock-

wise) until you locate the hole in the

Sleeve. With the oil can tube inside the

headstock apply 2-5 drops of oil in the

hole, as seen in Figure 113.:

Figure 113

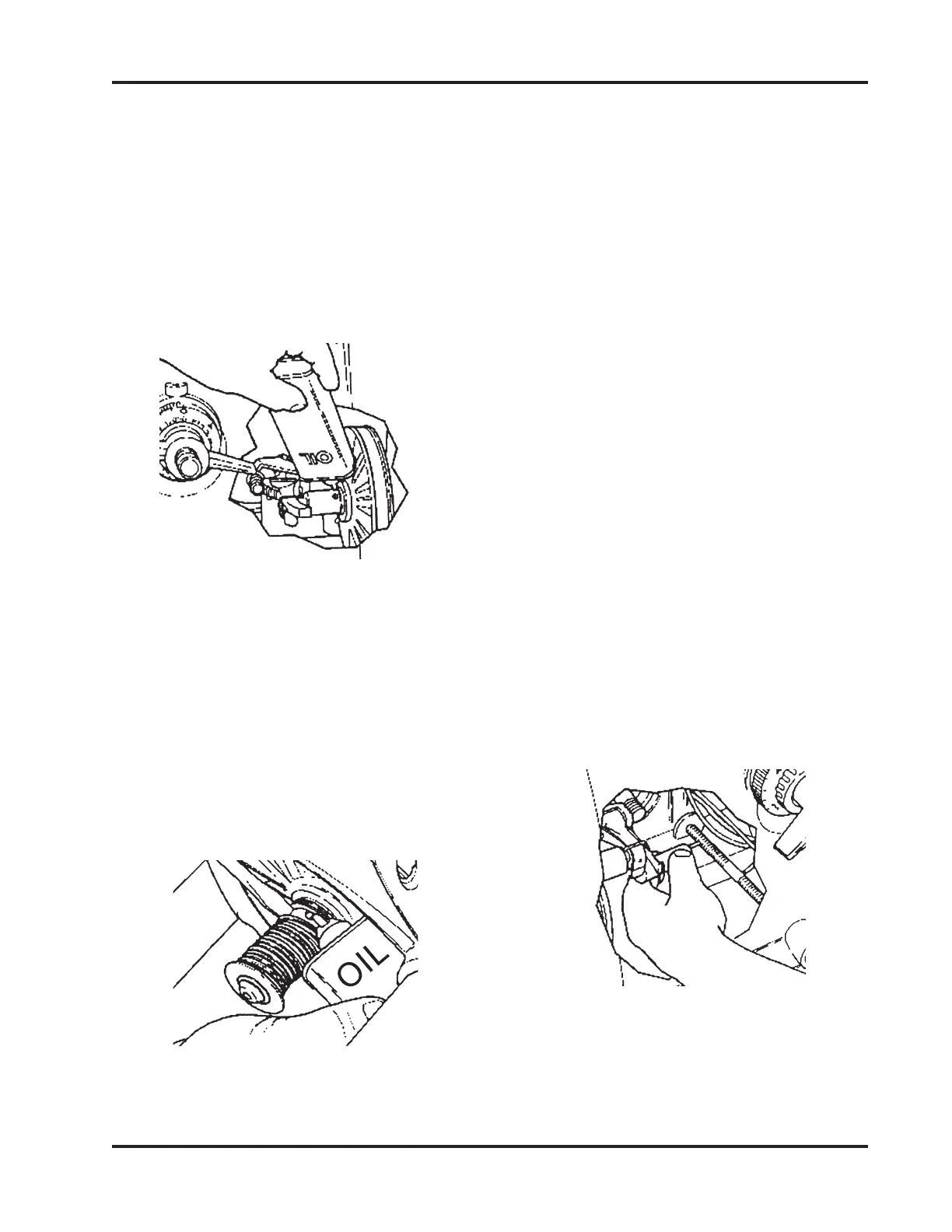

3. To oil the Lower Floating Sheaves, rotate

the Main Spindle by hand (clockwise)

until you find the hole in its Sleeve. This

hole may be difficult to find because of

the Motor Spring that fits over the Sleeve.

When you find the hole, spread the

Spring Coils that cover the hole with a

Large Straight Blade Screwdriver. Then

apply 2-5 drops of oil in the hole, as

shown in Figure 114.

Figure 114

Loading...

Loading...