911-352 Rev. H 10/99 Page: 2 of 2

SANITIZING

Potable water systems require periodic maintenance to deliver a consistent

flow of fresh water. Depending on use and the environment the system is

subject to, sanitizing is recommended prior to storing and before using the

water system after a period of storage. Systems with new components, or

ones that have been subjected to contamination, should also be disinfected

as follows:

NOTE:

The sanitizing procedure is in conformance with the approved

procedures of RVIA ANSI A119.2 and the U.S. Public Health Service.

1.

Use one of the following methods to determine the amount of common

household bleach needed to sanitize the tank.

A

) Multiply "gallons of tank capacity" by 0.13; the result is the ounces of

bleach needed to sanitize the tank.

B

)

Multiply "Liters of tank capacity" by 1.0; the result is the milliliters of

bleach needed to sanitize the tank.

2.

Mix into solution the proper amount of bleach within a container of water.

3.

Pour the solution

(water/bleach)

into the tank and fill the tank with potable water.

4.

Open

all

faucets

(Hot&Cold)

allowing the water to run until the distinct

odor of chlorine is detected.

5.

The standard solution must have four (4) hours of contact time to

disinfect completely. Doubling the solution concentration allows for

contact time of one

(1)

hour.

6.

When the contact time is completed, drain the tank. Refill with potable

water and purge the plumbing of all sanitizing solution.

WINTERIZING

If water is allowed to freeze in the system, serious damage to the plumbing

and the pump may occur. Failures of this type will void the warranty. The

best guarantee against damage is to completely drain the water system.

NOTE:

When used per the manufacturers recommendations

non-toxic

antifreeze for potable water

is safe for use with SHURflo pumps.

Refer to the coach manufacturer and other equipment

manufactures for their specific winterizing & drainage instructions.

CAUTION

:

Do not

use Automotive Antifreeze

to winterize potable water

systems. Such solutions are highly toxic. Ingestion may cause

serious injury or death.

To properly drain the system perform the following:

1.

Drain the water tank. If the tank doesn't have a drain valve, open all

faucets allowing the pump to operate

(15 min. ON / 15 min. OFF)

until the

tank is empty.

2.

Open all the faucets

(including the lowest valve or drain in the plumbing)

and allow the pump to purge the water from the plumbing, then turn the

pump OFF.

3.

Using a pan to catch the remaining water, remove the plumbing at the

pump's inlet/outlet ports. Turn the pump ON, allowing it to operate until the

water is expelled. Turn OFF power to the pump once the plumbing is

emptied. Do not reconnect pump plumbing. Make a note at tank filler as a

reminder: "Plumbing is Disconnected".

4.

All faucets must be left open to guard against any damage.

TROUBLESHOOTING

Vibration induced by road condition can cause plumbing or pump hardware to loosen. Check for system components that are loose. Many symptoms can

be resolved by simply tightening the hardware. Check the following items along with other particulars of your system.

PUMP WILL NOT START/ BLOWS CIRCUIT:

!

Electrical connections, fuse or breaker, main switch, and ground connection.

!

Is the motor hot? Thermal breaker may have triggered; it will reset when cool.

!

Is voltage present at the switch? Bypass the pressure switch. Does the

pump operate?

!

Charging System for correct voltage

(±10%)

and good ground.

!

For an open or grounded circuit, or motor; or improperly sized wire.

!

For seized or locked diaphragm assembly

(water frozen?)

.

WILL NOT PRIME/SPUTTERS:

(No discharge/Motor runs)

!

Is the strainer clogged with debris?

!

Is there water in the tank, or has air collected in the hot water heater?

!

Is the inlet tubing/plumbing sucking in air at plumbing connections

(vacuum leak)

?

!

Is inlet/outlet plumbing severely restricted or kinked?

!

Proper voltage with the pump operating

(±10%)

.

!"

For debris in pump inlet/outlet valves or swollen/dry valves.

!"

Pump housing for cracks or loose drive assembly screws.

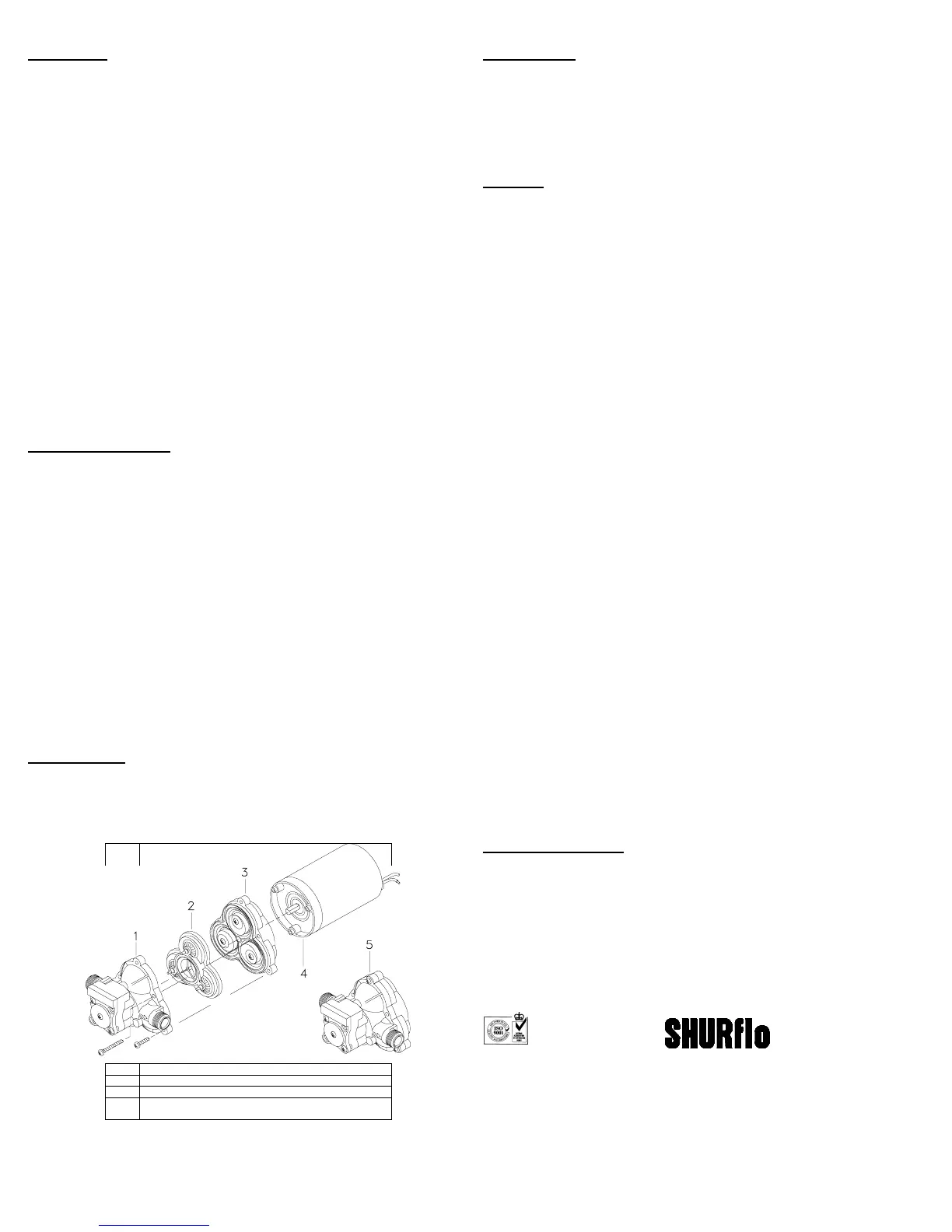

SERVICE KITS

To insure the correct service kit, order by the complete model number,

date of manufacture and other name plate data. Part kits come with

complete repair instructions. Pump illustrations may not be representative

of all SHURflo potable water pump models and are only for depiction of the

various parts kit assemblies.

1

Switch / Check valve and Upper Housing Kit

(Replaces all previous switch designs)

2

Valve plate assembly

3

Diaphragm / Drive assembly

4

Motor

5

Complete Pump Head assembly (includes parts

#

1, 2, 3)

(Replaces all previous switch designs)

PUMP WILL NOT SHUT-OFF / RUNS WHEN FAUCET IS CLOSED:

!

!!

!

Output side

(pressure)

plumbing for leaks, and inspect for leaky valves or toilet.

!

!!

!

For air trapped in outlet side

(water heater)

or pump head.

!

!!

!

For correct voltage to pump

(±10%)

.

!

!!

!

For loose drive assembly or pump head screws.

!

!!

!

Are the valves or internal check valve held open by debris or is rubber swollen?

!

!!

!

Pressure switch operation/adjustment, refer to shut-off adjustment for switch.

NOISY OR ROUGH OPERATION:

!

For plumbing which may have vibrated loose.

!

Is the pump plumbed with rigid pipe causing noise to transmit?

!

Does the mounting surface multiply noise

(flexible)

?

!

For mounting feet that are loose or are compressed too tight.

!

For loose pump head to motor screws.

(3 long screws)

!"

The motor with pump head removed. Is noise from motor or pump head?

RAPID CYCLING:

!

For restrictive plumbing, flow restrictors in faucets/shower heads.

!

Water filter/purifier should be on separate feed line.

!

Pressure switch shut-off adjustment.

LEAKS FROM PUMP HEAD OR SWITCH:

!

For loose screws at switch or pump head.

!

Switch diaphragm ruptured or pinched.

!"

For punctured diaphragm if water is present in the drive assembly.

LIMITED WARRANTY

SHURflo warrants its Potable Water pumps to be free from material and workmanship

defects under normal use and service for a period of two (2) years from the date of

manufacture indicated on the motor name plate.

The limited warranty will not apply to pumps that were improperly installed, misapplied, or

are incompatible with components not manufactured by SHURflo. Pump failure due to

foreign debris is not covered under the terms of this limited warranty. SHURflo will not

warrant any pump that is physically damaged, or altered outside the SHURflo factory.

Warranty claims may be resolved by an authorized dealer service center, or by a SHURflo

service center. Returns are to be shipped with charges pre-paid. Package all returns carefully.

SHURflo will not be responsible for freight damage incurred during shipping to a service center.

For complete Limited Warranty details consult Service Bulletin

#

1050

#

ISO Certified Facility

SHURflo reserves the right to update specifications, prices, or make substitutions.

SHURflo

#

##

#

12650 Westminster Ave.

Santa Ana, CA 92706-2100

(800) 854-3218 (714) 554-7709

FAX (714) 554-4721

Shipping/UPS:

12650 Westminster Ave.

Garden Grove, CA 92843

SHURflo East

52748 Park Six Court

Elkhart, IN 46514-5427

(800) 762-8094 (219) 262-0478

FAX (219) 264-2169

http://www.shurflo.com

© 1999 Printed in USA

SHURflo Ltd.

Unit 5 Sterling Park

Gatwick Road, Crawley

West Sussex, RH10 2QT

United Kingdom

+44 1293 424000

FAX +44 1293 421880

Loading...

Loading...