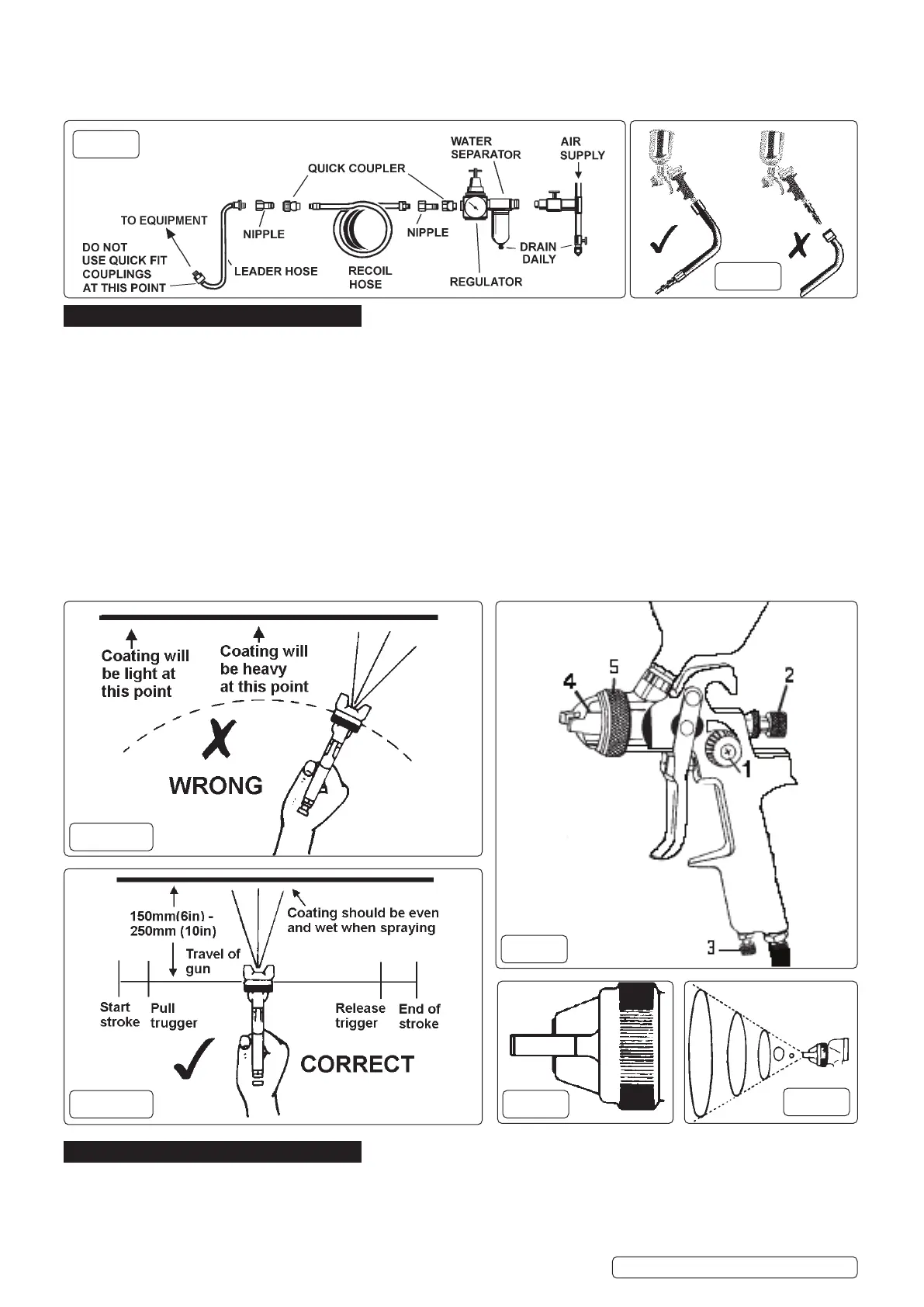

4.2. COUPLINGS

Vibration may cause failure if a quick change coupling is connected directly to the spray gun. To overcome this, connect

a leader hose to the spray gun. A quick change coupling may then be used to connect the leader hose to the air line recoil hose

(g.1 and 2).

5. OPERATION

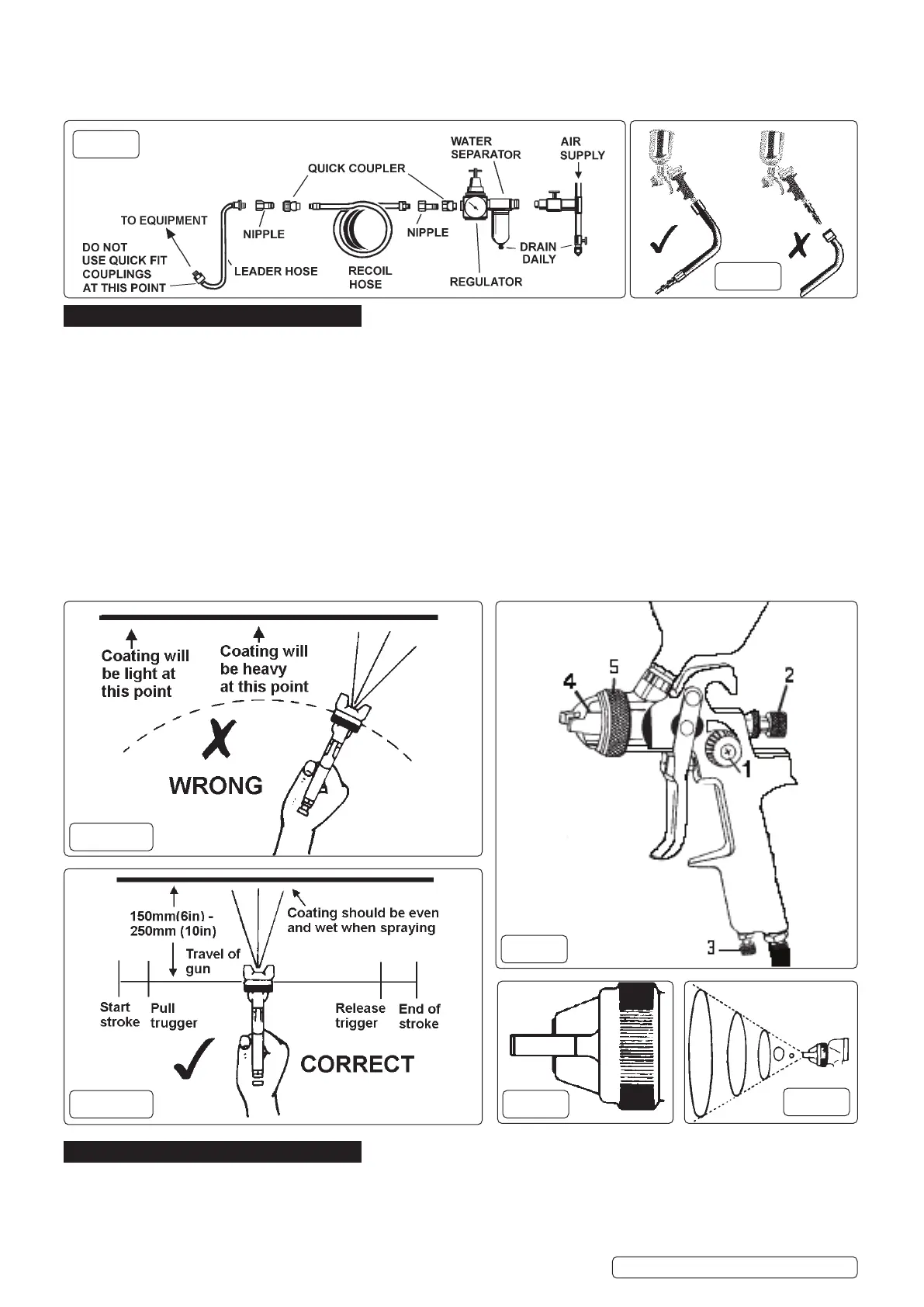

5.1. For best results, the gun should be held perpendicular to the surface being sprayed and moved parallel to it. Start the stroke before

squeezing the trigger and release the trigger before nishing the stroke. This will enable accurate control of the gun and material

(g.3B).

5.2. Spray from a distance of about 6 to 10 inches (150 to 250mm) depending on the material and the atomizing pressure. The material

deposited should always be even and wet. Each stroke must overlap the preceding stroke to obtain a uniform nish. To reduce

over-spray and obtain maximum efciency, spray with the lowest possible atomizing air pressure.

5.3. Controlling the fan spray and the uid.

a) Use the needle (paint) adjustment knob (g.4.2) to adjust the amount of paint ow.

b) The atomizing air ow is controlled by the control knob (g.4.1).

c) The volume of air input is controlled by the adjustment knob (g.4.3).

d) As width of spray is increased more material must pass through the gun to obtain the same coverage on the increased

area.

e) Turn the air nozzle (g.4.4) to achieve a horizontal or vertical fan spray. Lock the nozzle with retaining ring (g.4.5).

The spray pattern of the gun is variable from round to at with all patterns in between. In normal operation, the wings on

the nozzle are horizontal (g.5). This provides a vertical fan-shaped pattern which gives maximum, uniform and even

coverage when moving the gun back and forth, parallel to the work surface (g.6).

6. CLEANING/MAINTENANCE

FOR OPTIMUM PERFORMANCE IT IS VERY IMPORTANT TO ENSURE THE SPRAY GUN IS CORRECTLY CLEANED AFTER

EACH USE.

Disconnect from the air supply before attempting any cleaning or maintenance.

6.1. CLEANING THE GUN

6.1.1. Flush the gun through with clean solvent.

Original Language Version

© Jack Sealey Limited

g.1

g.2

g.3B

g.3A

g.4

g.5

g.6

S641G,S642G Issue 3 (H3F) 09/11/20

Loading...

Loading...