5.0 - INSTALLATION

5.1

-INSTALLING

THE

GEAR UNIT

I.\

The entire installation process must be planned as early as the general design phase

of

the ma-

~

chine. The person authorised to do the

work

must,

if

necessary, set out a safety plan to protect

• the health and safety

of

all persons directly involved and apply all applicable legislation.

1.

Carefully remove all packaging and protective produet residue from the gear unit.

Pay particular attention to the mating surfaces.

2.

Check that the data

on

the nameplate correspond to those specified in the purehase arder.

3.

Ensure that the structure to which the gear unit is to be mounted is sufficiently robust and rigid to support

its weight and operating stresses.

4. Check that the machine to which the gear unit is to be installed is switched off and cannot be accidentally

switched

on

again.

5.

Make sure all mating surfaces are flat.

6.

Make sure the shafUshaft or shafU bore are perfectly aligned for coupling.

7.

Fit suitable guards

to

protect against the gear unit's external moving parts.

8.

lf

the work environment is corrosive for the gear unit or any of its parts, follow the special precautions re-

quired for aggressive environments.

In

this case, contact the BONFIGLIOLI TRASMITAL sales service.

9.

We recommend applying a protective paste to all gear unit/motor mating surfaces and other parts

(Kluberpaste 46 MR

401

or other produet with similar properties and application range) to ensure optimal

coupling and protection against fretting corrosion.

10.

In

the case of outdoor installations fitted with

an

electric motor, protect the latter from direct sunlight and

the weather by means of guards or a casing. Also make sure that the assembly is properly ventilated.

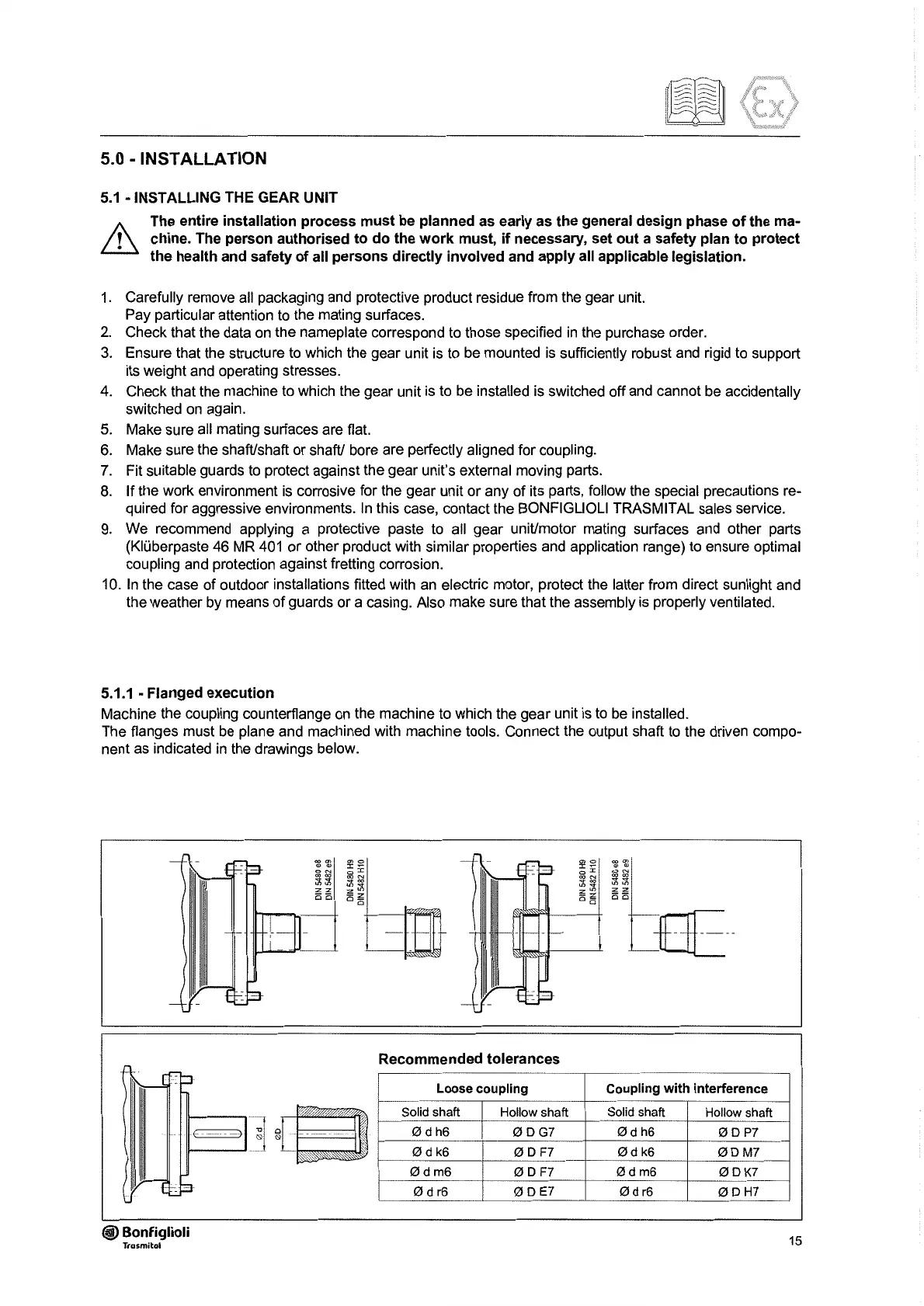

5.1.1

• Flanged execution

Machine the coupling counterflange

on

the machine to which the gear unit is to

be

installed.

The flanges must

be

plane and machined with machine tools. Connect the output shaft

to

the driven compo-

nent

as

indicated

in

the drawings below.

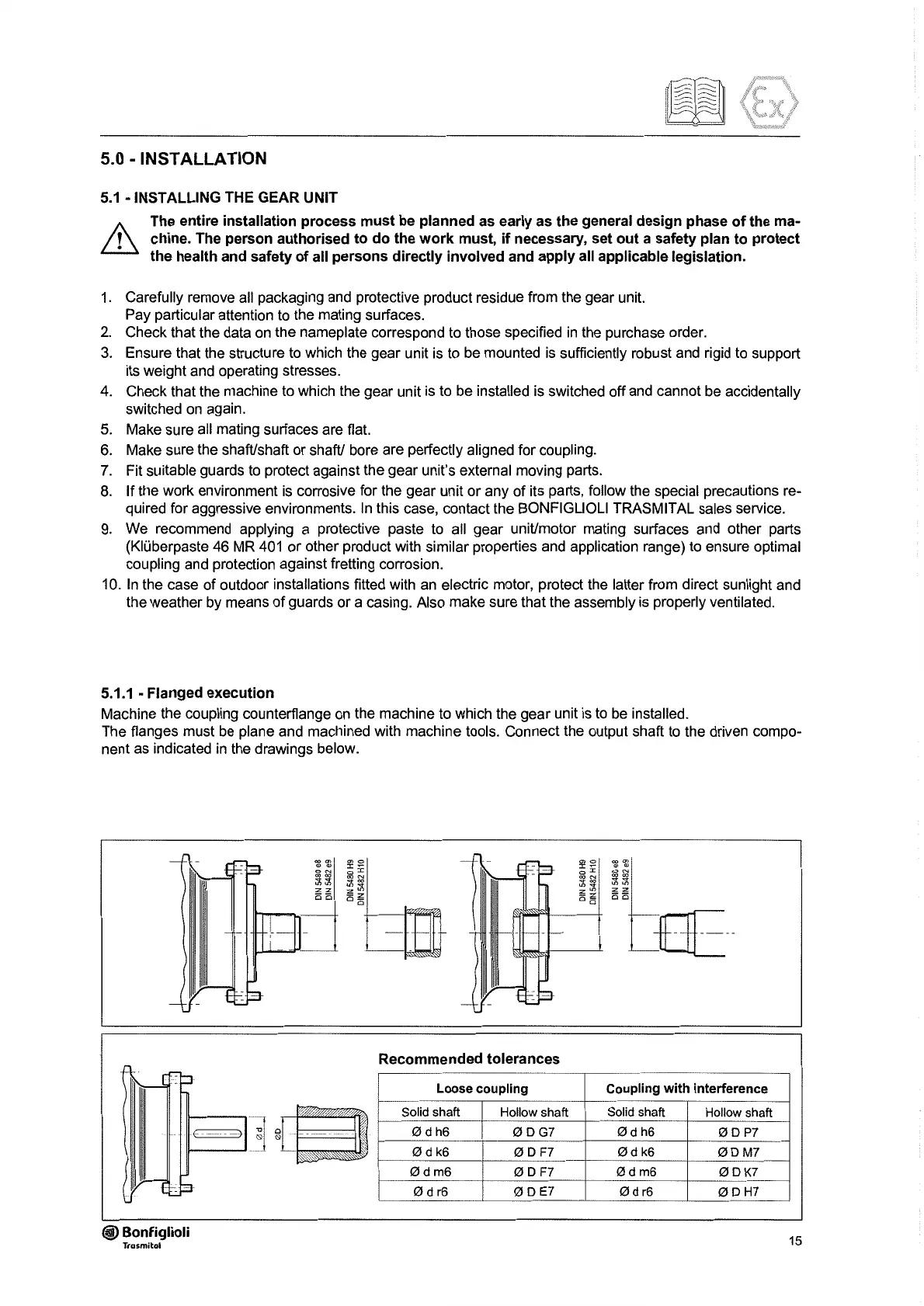

Recommended tolerances

Loose coupling Coupling

with

interference

Solid shaft Hollow shaft Solid shaft

Hollow shaft

Ødh6

ØDG7

Ød

h6

ØDP7

Ød

k6

ØD

F7

Ød

k6

ØDM7

e

~>1g

'

Ødm6

ØD

F7

Ødm6

ØDK7

ød

r6

ØDE?

ød

r6

ØDH7

@ Bonfiglioli

Trasmitol

15

Loading...

Loading...