14BMounting, installation

Standard motors

42 56100000002001, 02/2013

Note

Measures conforming to ISO 10816 must be taken in order to compensate any offset

between electrical machines and driven machines.

The foundation must be designed according to DIN 4024.

5.4 Alignment and fastening

General

When aligning and fastening the machine, please bear the following in mind:

● The machine must be level.

● Feet and flanges must be fastened securely.

● Alignment must be precise in the case of direct coupling.

● Fastening surfaces must be clean

● Look out for any damage to paint; this must be rectified immediately and

correctly.

● Look out for traces of anti-corrosion protection agents; these must be removed

using mineral turpentine.

● Look out for installation-related resonances with the rotating frequency and

double line frequency; these must be prevented.

● Listen for unusual noises when turning the rotor manually.

● Check the direction of rotation with the machine decoupled.

● Avoid using rigid coupling measures.

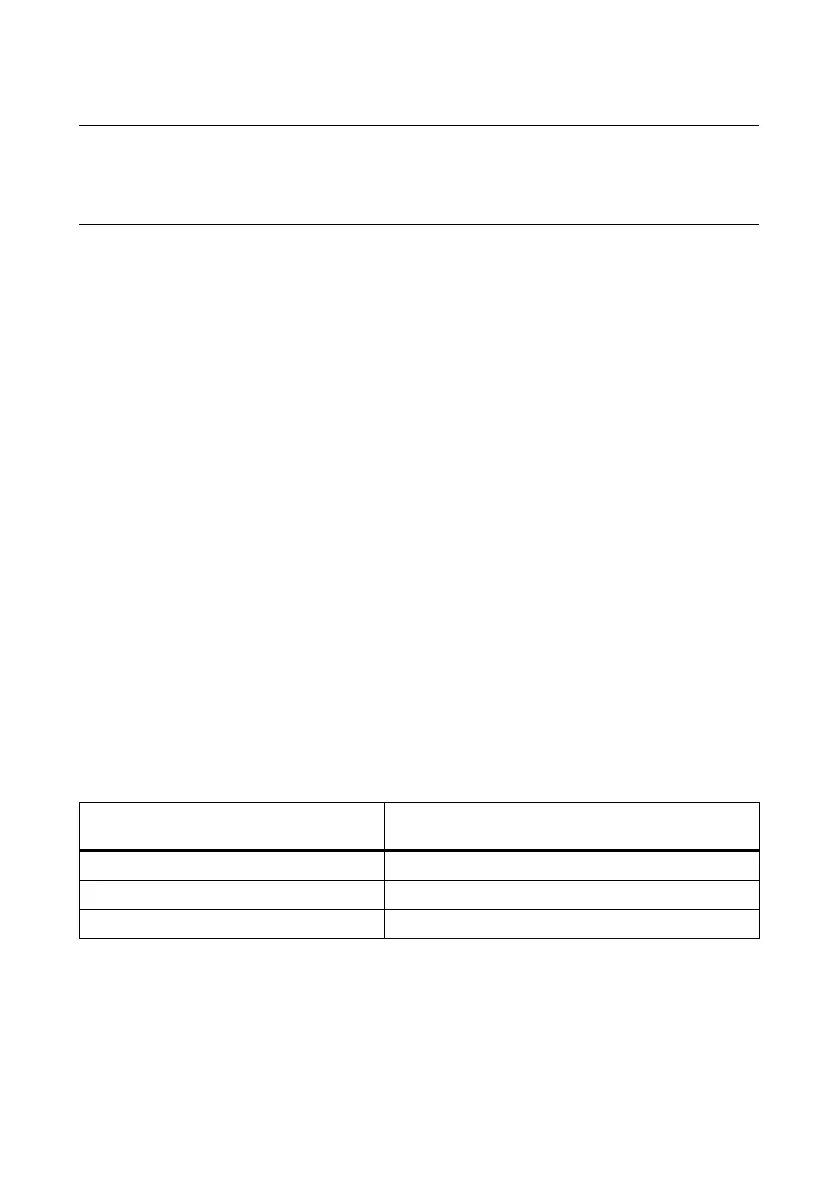

Flatness of the supporting surfaces for conventional motors

Frame size

(FS)

Flatness

mm

≤ 132 0.10

160 0.15

≥ 180 0.20

Loading...

Loading...