AP09 Datum 04.05.2000 Art.Nr. 78091 Z.Nr. 8665013 Änd.Stand 140/00 9

ENGLISH

1. Safety information

In order to carry out installation correctly, we

strongly recommend this document is read very

carefully. This will ensure your own safety and

the operating reliability of the device.

• Your device has been quality controlled, te-

sted and is ready for use. Please respect all

warnings and information which are marked

either directly on the device or in this document.

• Warranty can only be claimed for components

supplied by SIKO GmbH. If the system is used

together with other products, the warranty for the

complete system is invalid.

• Repairs should be carried out only at our

works. If any information is missing or unclear,

please contact the SIKO sales staff.

2. Identification

Please check particular type of unit and type

number from the identification plate.Type num-

ber and the corresponding execution are indica-

ted in the delivery documentation.

e.g. AP09-0023

type number

type of unit

3. Installation

The unit should be used only according to the

protection level provided. Protect the unit, if

User Information

AP09

Absolute / Incremental Electronic

Position Indicator

necessary, against environmental influences

such as sprayed water, dust, knocks, extreme

temperatures.

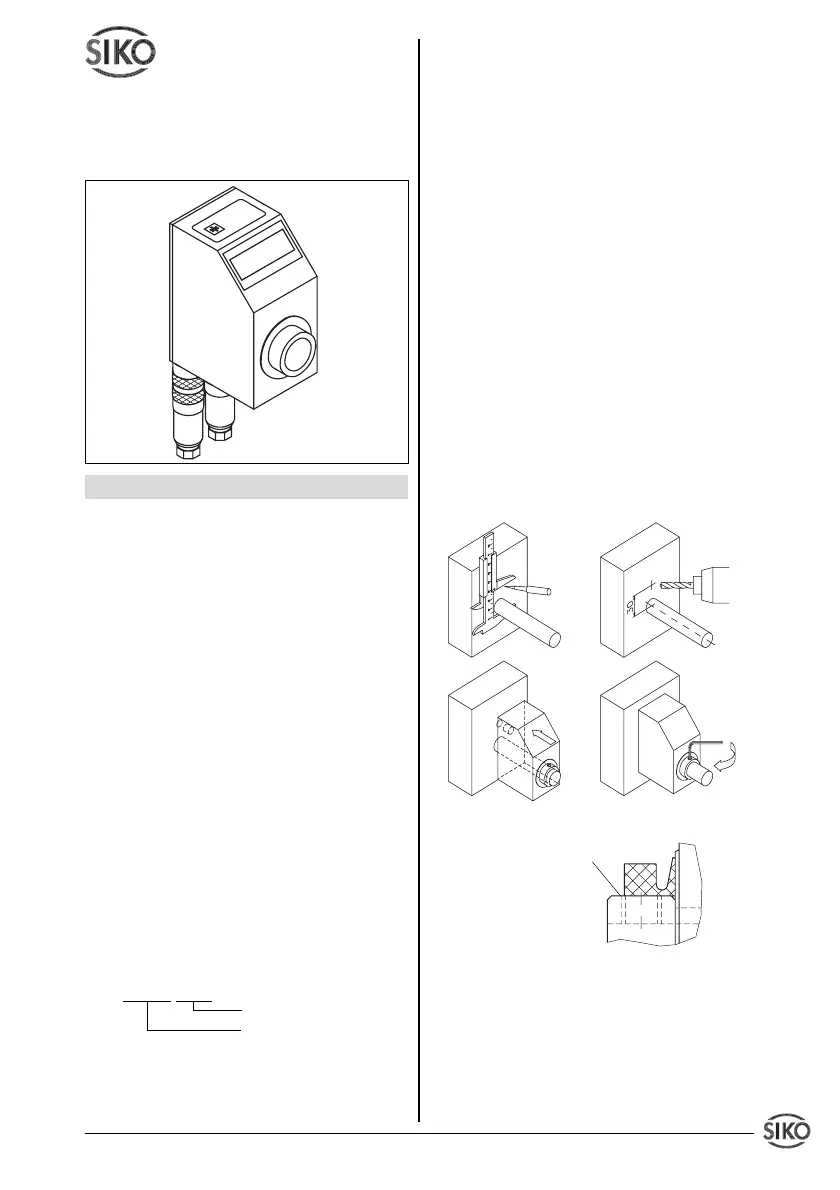

Slide AP09 onto the solid shaft, insert torque pin

into the prebored mounting hole and use grub

screw M5 to fix the AP09's hollow shaft to the

machine's solid shaft (see fig. 1).

• Ensure sliding fit between solid shaft and AP09.

• Ensure accurate shaft alignment and mount

the AP09 without force. Do not exceed the

values for the maximum axial and radial shaft

load. If the shaft is not correctly aligned, strain

on the bearings will result, which may cause

overheating and irreparable damage.

• Especially when using torque pin type A for

fixing, ensure that AP09 does not jam and that

it is mounted without strain. Please remember

this when choosing the AP09's bore diameter.

• Knocks on the unit should be avoided!

• Make sure that the axial seal is correctly

mounted ! (see fig. 2)

Fig. 1: Mounting instructions

Fig. 2: Axial seal

4. Electrical connection

• Switch power off before any plug is inserted or

removed.

• Wiring must only be carried out with power off.

• Provide standed wires with ferrules.

• Check all lines and connections before swit-

Torque pin type A : pin ø 6 h9

type B : bore ø 10 +0.8

Grub screw has to

be screwed in flush

to surface

Loading...

Loading...