45

EN

The boiler must be installed in a fixed loca-

tion and only by specialized and qualified

firms in compliance with all instructions

contained in this manual. Furthermore, the

installation must be in accordance with cur-

rent standards and regulations.

2.1 INSTALLATION

-

In the rooms where “Type B” boilers

are installed, the air required for correct

combustion of the gas consumed by the

appliance must be able to flow in. It is

therefore necessary to make openings

that cannot be blocked in the outer walls,

which must be at least 6 cm

2

for every

kW of thermal capacity installed and with,

in any case, a minimum of 100 cm

2

.

- “Type C” appliances, with combustion

chamber and air supply sealed off from

the environment, can be installed in any

room in the house.

- “Type B and C” boilers are suitable for

functioning in a partially protected place,

as according to EN 297, with maximum

environmental temperature of 60°C and

minimum of -5°C. We recommend installa-

tion of these boilers under the protruding

slope of a roof, on a balcony, or in a pro-

tected niche, always providing they are not

directly exposed to adverse weather (rain,

hail, snow). The boilers are provided alre-

ady equipped with anti-freeze functions.

2.1.1 Anti-freeze function

The boilers are equipped with anti-freeze

function which activates the pumps and the

burner when the temperature of the water

contained inside the appliance drops to

below 6°C. The anti-freeze function is ensu-

red, however, only if:

- the boiler is correctly connected to the

gas and electricity supply circuits;

- the boiler is constantly fed;

- the boiler ignition is not blocked;

- the essential components of the

boiler are all in working order

In these conditions the boiler is protected

against frost down to an environmental

temperature of -5°C.

ATTENTION: In the case of installation in a

place where the temperature drops below

0°C, the connection pipes must be protected.

2.2 COMPLEMENTARY ACCESSORIES

To facilitate connecting the boiler to the

system, the following accessories can be

supplied on request, complete with instruc-

tions for assembly:

- Installation plate code 8075438.

- Curvette and gas taps/sanitary water

output set code 8075418.

- Taps kit code 8091806.

- Taps kit boiler BFT code 8091820.

- Hydraulic connection kit boiler BFT/

BT100 tank unit code 8091113.

- Kit of couplings for replacing wall-hung

boilers of other makes code 8093900.

- Solar kit INSOL only for heating boilers

code 8092235.

- Solar kit for the instantaneous boilers

code 8105101 in coupling to kit INSOL.

- Mixed area kit ZONA MIX code 8092234.

- Antifreeze heaters kit -15°C code

8089806 (BF-BFT models).

2.3 CONNECTING UP SYSTEM

To protect the heat system from damaging

corrosion, incrustation or deposits, before

installation it is extremely important to clean

the system using suitable products such as,

for example,

Sentinel X300 (new systems),

X400 and X800 (old systems) or Fernox

Cleaner F3

. Complete instructions are pro-

vided with the products but, for further infor-

mation, you may directly contact

SENTINEL

PERFORMANCE SOLUTIONS LTD or FERNOX

COOKSON ELECTRONICS

. For long-term pro-

tection agains corrosion and deposits, the

use of inhibitors such as

Sentinel X100 or

Fernox Protector F1

is recommended after

cleaning the system. It is important to check

the concentration of the inhibitor after each

system modification and during maintenan-

ce following the manufacturer’s instructions

(specific tests are available at your dealer).

The safety valve drain must be connected to

a collection funnel to collect any discharge

during interventions. If the heating system is

on a higher floor than the boiler, install the

on/off taps supplied in kit optional on the

heating system delivery/return pipes.

WARNING: Failure to clean the heat

system or add an adequate inhibitor inva-

lidates the device’s warranty.

Gas connections must be made in accor-

dance with current standards and regula-

tions. When dimensioning gas pipes from

the meter to the module, both capacity volu-

me (consumption) in m

3

/h and gas density

must be taken into account.

The sections of the piping making up the

system must be such as to guarantee a

supply of gas sufficient to cover the maxi-

mum demand, limiting pressure loss betwe-

en the gas meter and any apparatus being

used to not greater than:

– 1.0 mbar for family II gases (natural gas);

– 2.0 mbar for family III gases (butane or

propane).

An adhesive data plate is sticked inside the

front panel; it contains all the technical data

identifying the boiler and the type of gas for

which the boiler is arranged.

2.3.1 Filter on the gas pipe

The gas valve is supplied ex factory with an

inlet filter, which, however, is not adequate

to entrap all the impurities in the gas or in

gas main pipes. To prevent malfunctioning

of the valve, or in certain cases even to cut

out the safety device with which the valve is

equipped, install an adequate filter on the

gas pipe.

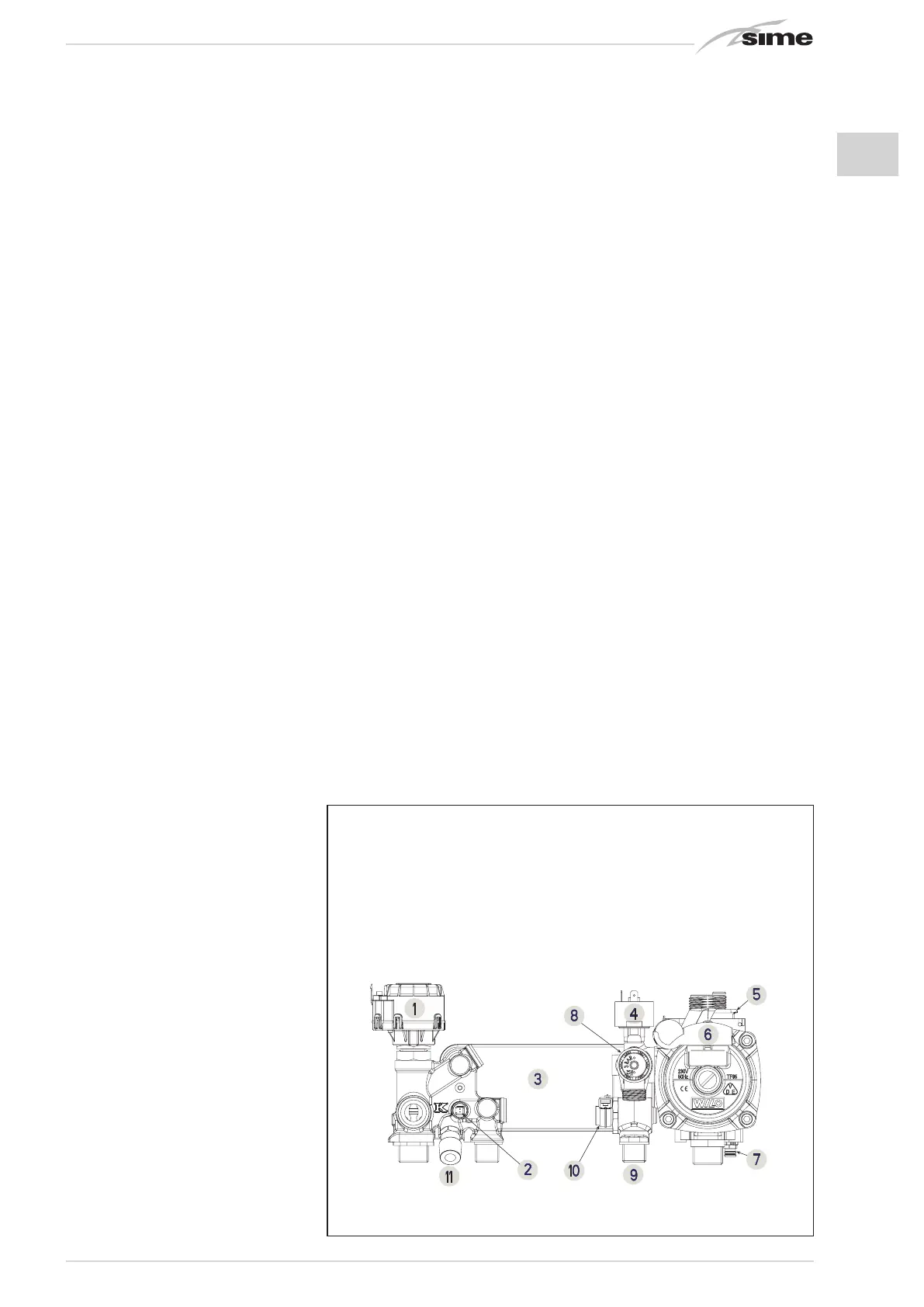

2.5 SYSTEM FILLING (fig. 4)

Filling of the boiler and the system is done by

the system filling (11). The charge pressure,

2 INSTALLATION

Fig. 4

45

KEY

1 Diverter valve (VD)

2 D.H.W. sensor (SS)

3 D.H.W. exchanger with plates

4 Water pressure transducer (TPA)

5 Air release vent

6 Circulator (PI)

7 Boiler discharge

8 3 BAR safety valve

9 D.H.W. filter

10 D.H.W. flowmeter sensor

11 System loading

Loading...

Loading...