9

1.4 ERRORS

AND SOLUTIONS

When there is a functioning error, the

display shows an alarm and the blue

luminous bar becomes red.

Descriptions of the errors with the

relative alarms and solutions are given

below:

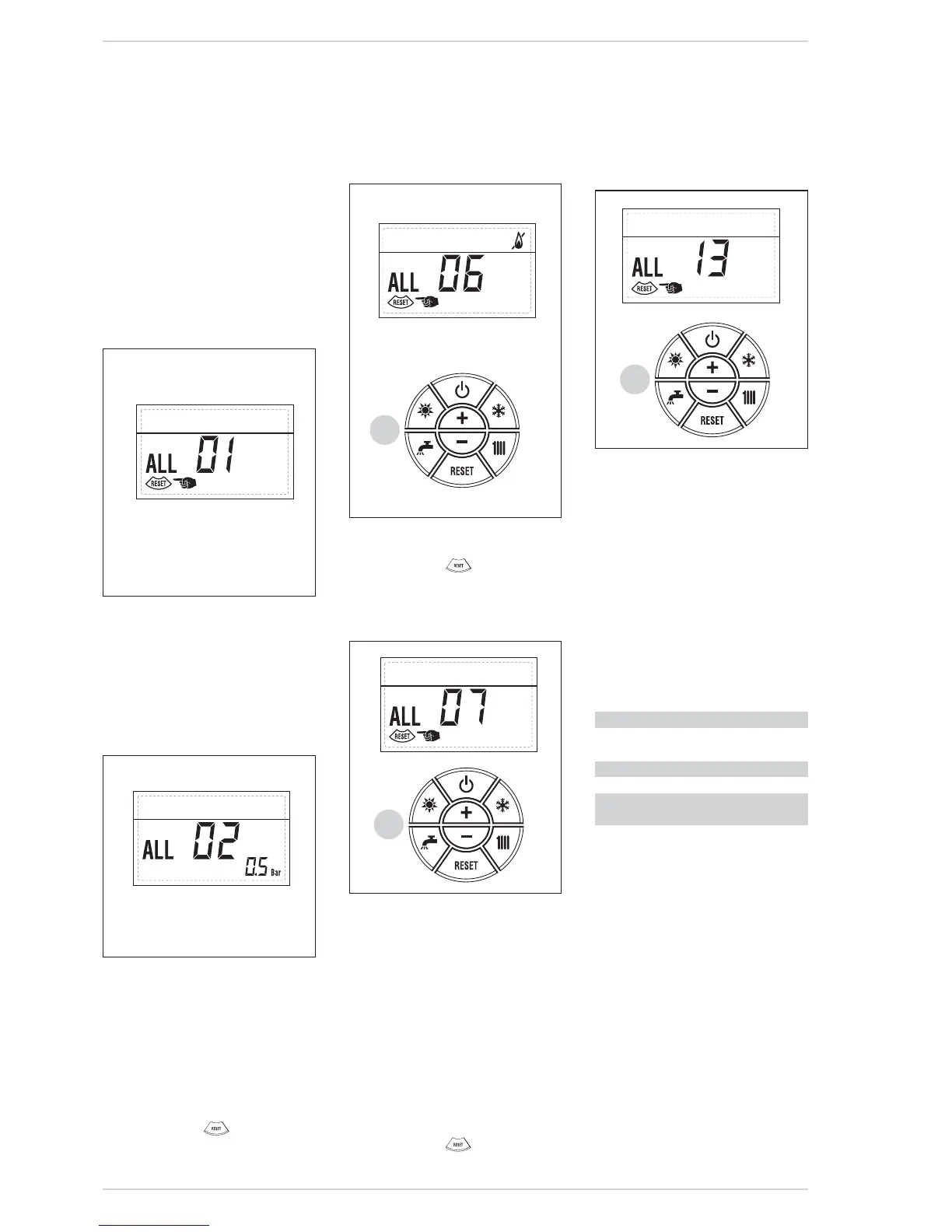

– ALL 01 (fig. 27)

Seek help and advice from a quali-

fied engineer.

– ALL 02 (fig. 27/a)

If the water pressure detected is

lower than 0.5 bar, the boiler will

stop and the display will show “ALL

02”. To proceed increase the

system pressure to between 1 and

1.5 bar.

– ALL 03

Seek help and advice from a quali-

fied engineer.

– ALL 05

Seek help and advice from a quali-

fied engineer.

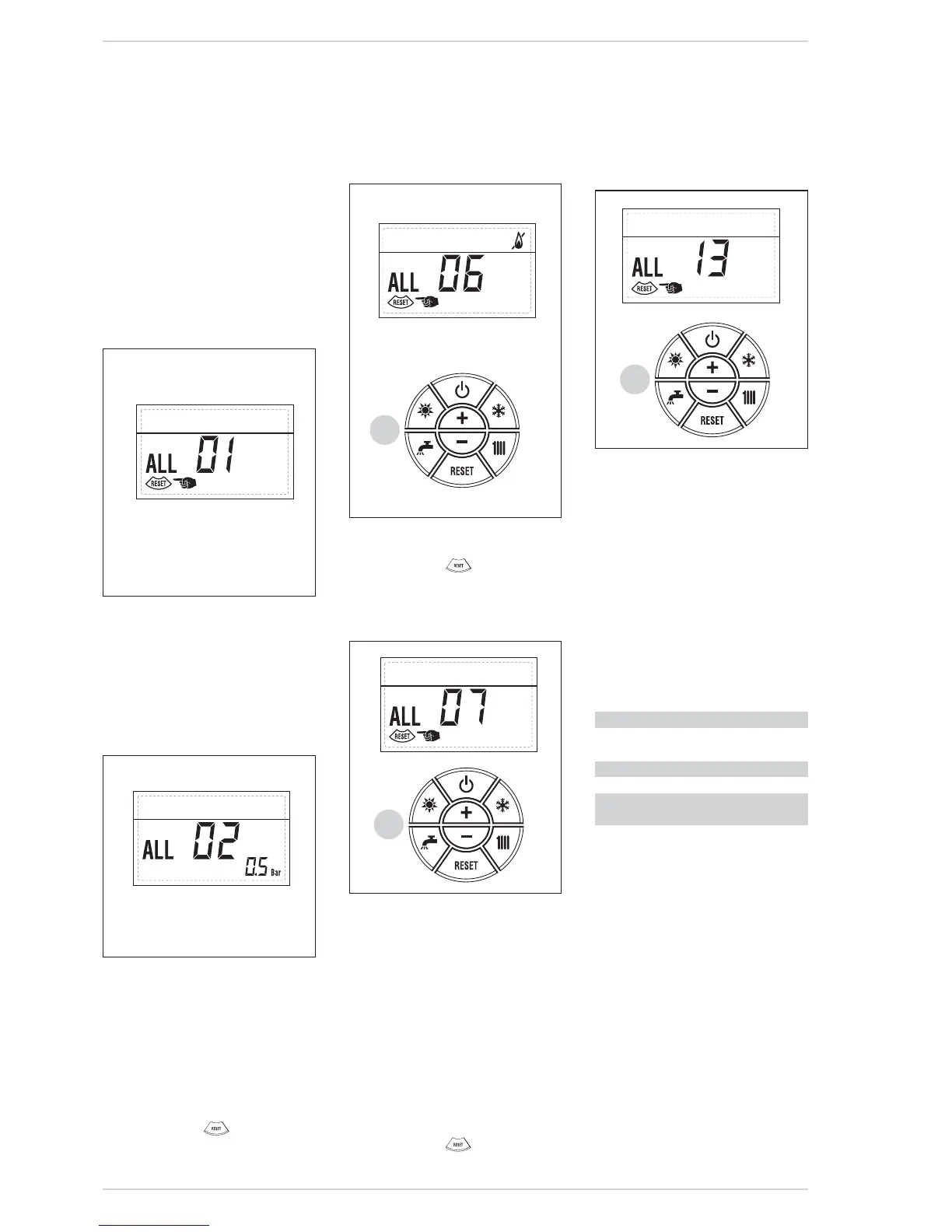

– ALL 06 (fig. 27/c)

Press the key f the controls

(2) to re-start the boiler.

If the error persists seek help and

advice from a qualified engineer.

– ALL 07 (fig. 27/d)

Press the key of the controls

(2) to re-start the boiler.

If the error persists seek help and

advice from a qualified engineer.

– ALL 08

Seek help and advice from a quali-

fied engineer.

– ALL 09

Seek help and advice from a quali-

fied engineer.

– ALL 10

Seek help and advice from a quali-

fied engineer.

– ALL 13 (fig. 27/e)

Press the key of the controls

(2) to re-start the boiler.

If the error persists seek help and

advice from a qualified engineer.

– ALL 14

Seek help and advice from a quali-

fied engineer.

– ALL 15

Seek help and advice from a quali-

fied engineer.

1.5 MINIMUM CLEARANCES

The following MINIMUM CLEARANCES

must be available for servicing the

appliance:

1.6 ROUTINE SERVICING

To ensure continued efficient opera-

tion of the appliance, it is recommend-

ed that it is checked and serviced as

necessary at regular intervals.

The frequency of servicing will depend

upon the particular installation condi-

tions and usage but in general once a

year should be adequate. It is the law

that any service work must be carried

out by a registerd person (C.O.R.G.I.).

Loading...

Loading...