90

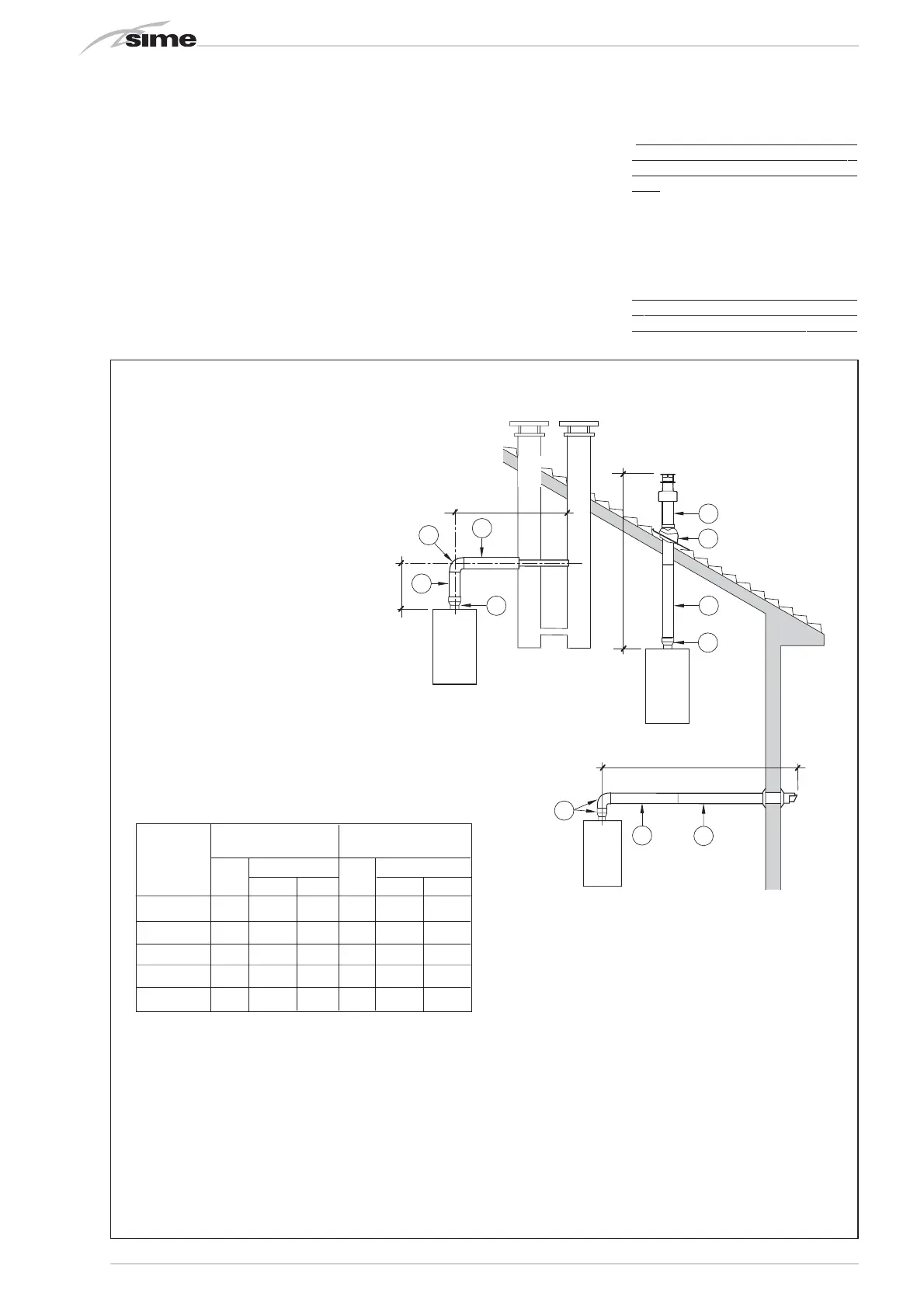

2.6 INSTALLATION OF SEPARATE

DUCTS ø 80 - ø 60

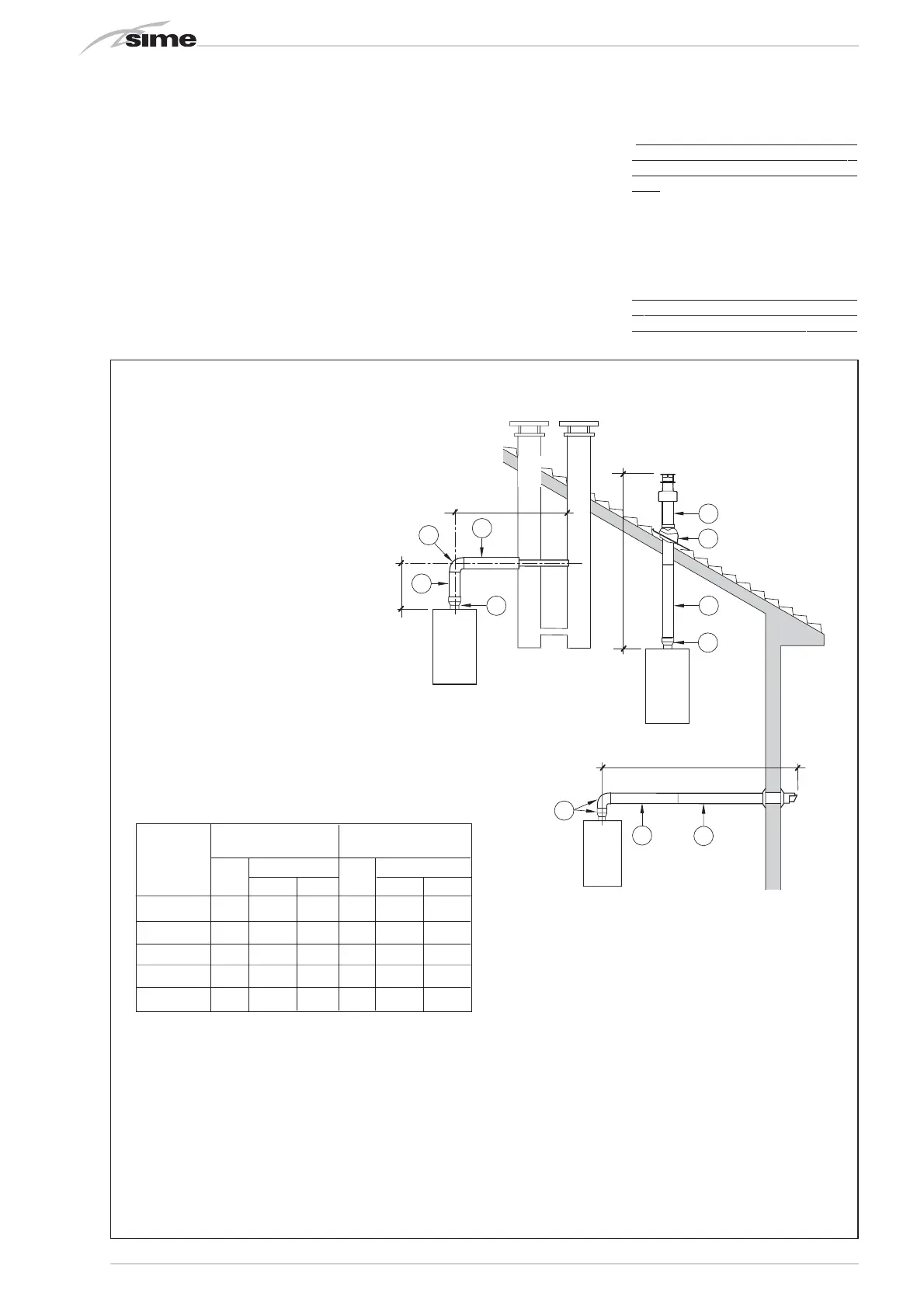

(fig. 7 - fig. 8)

The kit with dedicated pipes enables to

separate the exhaust fumes pipes from the

air suction pipes (fig. 7):

- The kit with dedicated ø 80 pipes, code.

8089912, includes a SUCTION DIAPH-

RAGM THAT IS NOT used for these

models. To be able to use the air tap, cut

its base with a tool (A) and assemble it

(B).

- The kits with dedicated ø 60 pipes, code

8089913, include a suction collar that

replaces the boiler collar (C).

It is now possible to insert an expansion or

bend in polypropylene without gaskets or

sealant.

The maximum overall length, resulting

from the sum of all the suction and

discharge pipes, is determined by the

load losses of the single connected acces-

sories and should not exceed 15 mm H2O

(ATTENTION: the total length of each pipe

should not exceed 50 m, even if the total

loss is below the maximum applicable

loss.)

See Table 1-1/a for information on the

load losses of single accessories and the

example of fig. 8 for information on how to

calculate load losses.

ATTENTION: Only the “25-30” versions

are supplied with steel diaphragm code

6028605 to be positioned on the fumes

Fig. 6

LIST OF ø 60/100 ACCESSORIES

1

Coaxial duct kit code 8096250

2a Extension L. 1000 code 8096150

2b Extension L. 500 code 8096151

3 Vertical extension L. 140 with coupling code 8086950

4a Additional 90° curve code 8095850

4b Additional 45° curve code 8095950

5 Tile for joint code 8091300

6 Terminal for roof exit L. 1285 code 8091205

IMPORTANT:

- The insertion of each additional 90° bend

with a diameter of 60/100 reduces the

available section by 1.5 meters.

- The insertion of each additional 90° bend

with a diameter of 80/125 reduces the

available section by 2 meters.

- Each additional 45° curve installed redu-

ces the available length by 1.0 metres.

- During assembly it is important to make

sure that the kit with axial pipes. (1) is

positioned horizontally.

NOTE

Before connecting accessories, it is always

advisable to lubricate the internal part of

the gaskets with silicon products. Avoid

using oils and greases.

Model Length of pipe Length of pipe

ø 60/100 ø 80/125

LH LH

Min Max Min Max

25 6 m 1.3 m 8 m 12 m 1.2 m 15 m

25 T 6 m 1.3 m 8 m 12 m 1.2 m 15 m

30 5 m 1.3 m 7 m 10 m 1.2 m 13 m

35 4 m 1.3 m 6 m 8 m 1.2 m 11 m

35 T 4 m 1.3 m 6 m 8 m 1.2 m 11 m

LIST OF ø 80/125 ACCESSORIES

1 Coaxial duct kit code 8096253

2a Extension L. 1000 code 8096171

2b Extension L. 500 code 8096170

3 Adapter for ø 80/125 code 8093150

4a Additional 90° curve code 8095870

4b Additional 45° curve code 8095970

5 Tile for joint code 8091300

6 Terminal for roof exit L. 1285 code 8091205

Loading...

Loading...