26

CATALYTIC SELF CLEAN PANELS

Catalytic Self Clean Panels are available as an optional accessory.

Operation

Catalytic self clean panels are coated with a specially formulated enamel coating, over a base of

regular enamel. This enamel coating has a rough surface which is also porous. During normal cooking,

fats and other food spatter is partially absorbed into the surface and then oxidises away.

This oxidisation of the fat works best if the oven is set at high temperatures. Users will find that if

they do a lot of lower temperature baking, say around the normal 180°C, then the cleaning process

may not be complete. Every now and then the user should turn the oven on to 260°C for around one

hour to completely remove the soil.

Cleaning

Should the panels become heavily soiled, they will need to be taken out of the oven and cleaned

by hand. They should be soaked in warm, soapy water for at least 2 hours and then wiped clean with

a soft cloth. Solid cleaning powders, creamy cleansers, caustic oven cleaners, steel wool or other

scourers will ruin the catalytic surface and must NEVER BE USED.

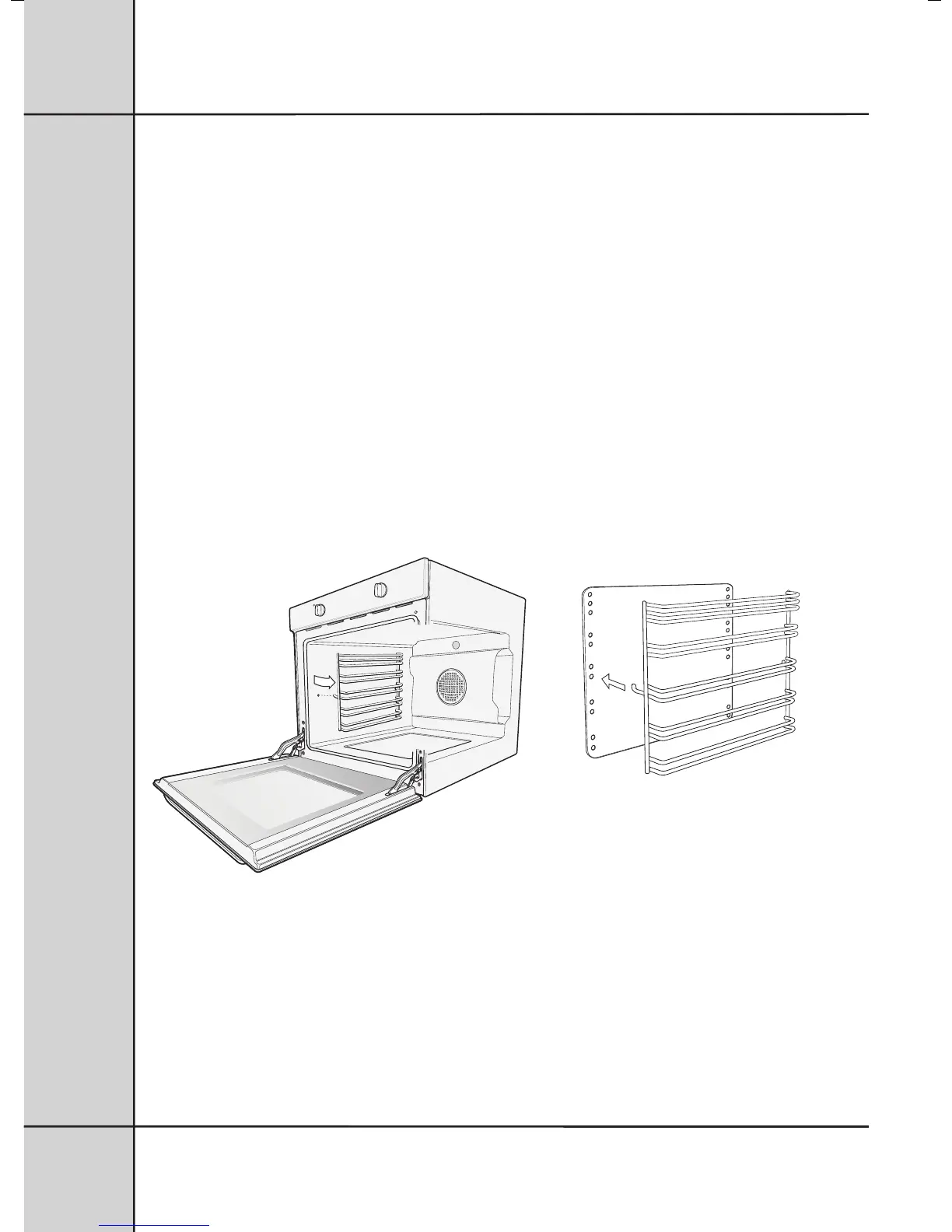

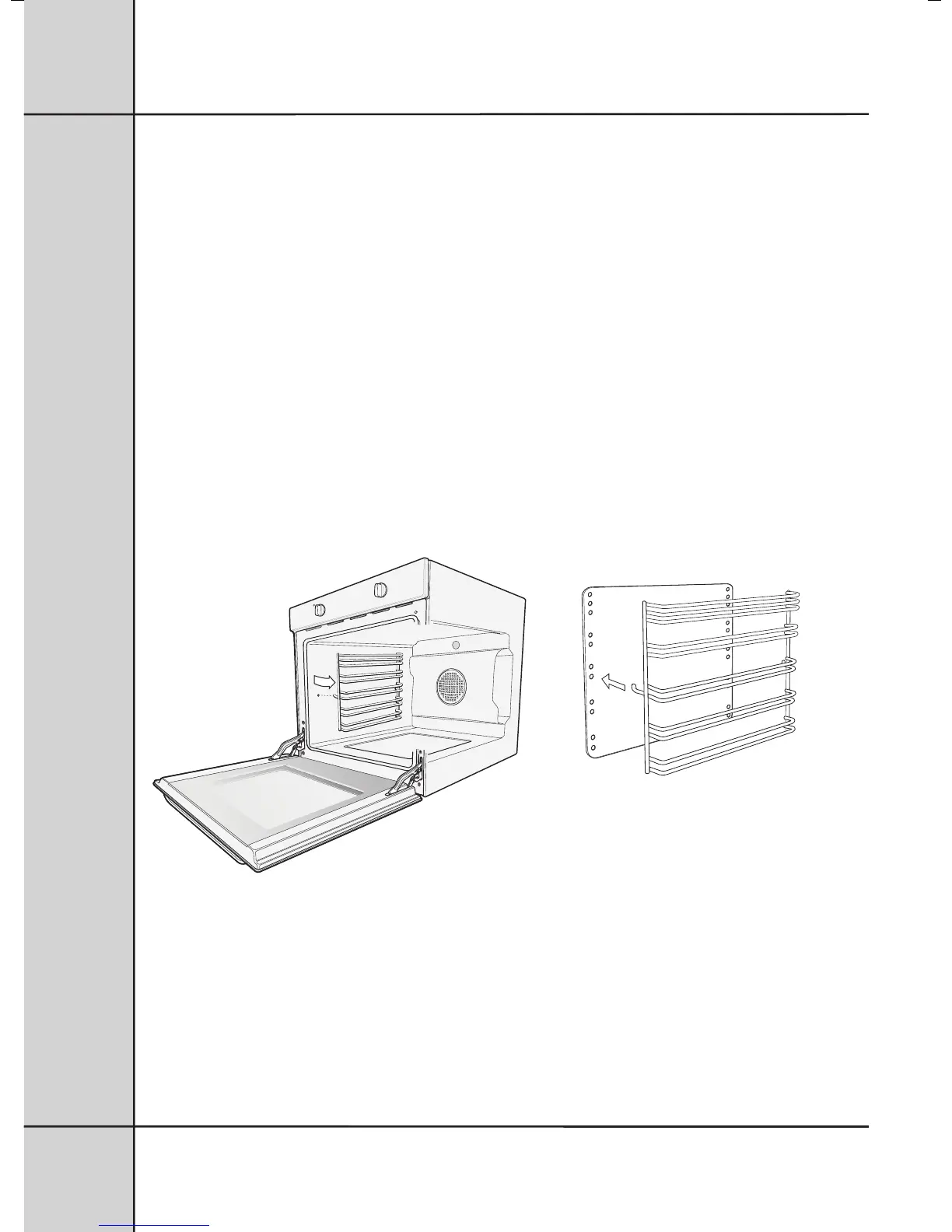

Removing the catalytic liners

• Grasp the shelf supports at the front.

• Pull them inwards.

• Separate the catalytic liners from the shelf

supports.

Installing the catalytic liners

• Align the shelf support to the catalytic liner by

aligning the rails with the corresponding holes.

• Ensure the catalytic surface is facing the shelf

support.

• Clip the shelf support to the catalytic liner.

• Fit the liner and shelf support assembly to the

oven inserting the rear hook to the rear hole in

the oven. Then locate the front peg into the front

hole and push in firmly.

• A Catalytic liner kit can be ordered under Part

No. CKCLK1.

3

Loading...

Loading...