SINAMICS G120

Standard inverters 0.37 kW to 250 kW (0.5 hp to 400 hp)

Supplementary system components

Safe Brake Relay

4/110

Siemens D 11.1 · 2009

4

■

Overview

The Safe Brake Relay allows the Power Module to be safely con-

nected to an electromechanical motor brake, allowing the brake

to be directly and safely controlled by the Control Unit in accor-

dance with EN 954-1 Safety Category 3 and IEC 61508 SIL 2.

■

Selection and ordering data

■

Integration

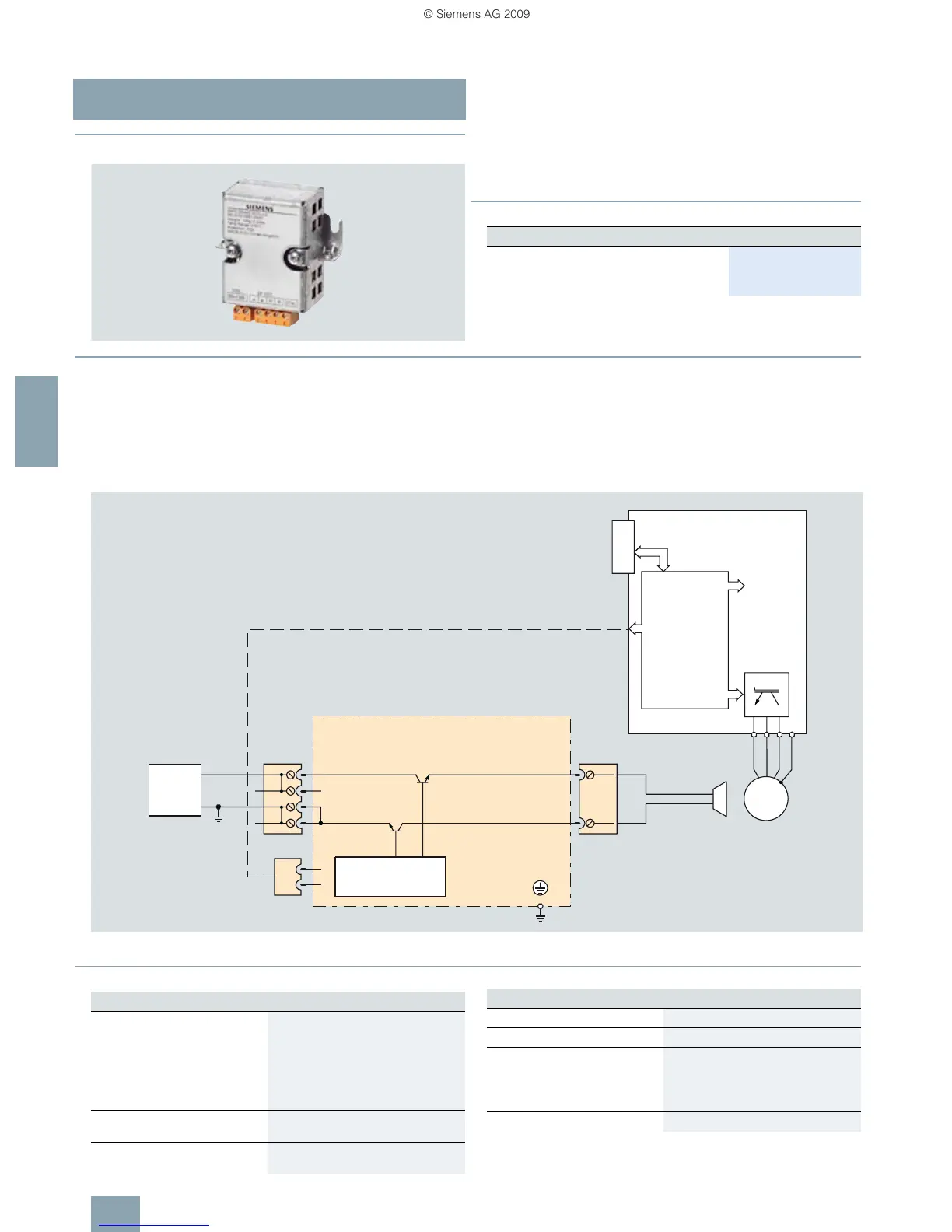

The Safe Brake Relay has the following interfaces:

• A two-channel transistor output stage to control the motor

brake solenoid

• A connection for a 24 V DC power supply

• A connection for the cable harness (CTRL) for connection to

the Power Module

The Safe Brake Relay can be mounted on the shield bonding

plate near the power terminals of the Power Module.

The supplied Safe Brake Relay includes the cable harness for

connection with the Power Module.

The 24 V DC solenoid of the motor brake is directly connected to

the Safe Brake Relay. External surge suppressors are not re-

quired.

Connection example of a Safe Brake Relay

■

Technical specifications

Order No.

Safe Brake Relay

Including cable harness for connection to the

Power Module

6SL3252-0BB01-0AA0

U2

V2

W2

PE

M

3 ~

Power

Module

Safe Brake Relay

CTRL

M

+

M

+

M

+

BR-

BR+

G_D211_EN_00071

ext.

24 V

PM-IF interface

Cable harness

Safe Brake Relay

Supply voltage 20.4 … 28.8 V DC

Recommended rated value of the

26 V DC supply voltage

(to equalize and compensate for the

voltage drop along the feeder cable

to the 24 V DC solenoid of the motor

brake)

Max. current requirement of

motor brake

2A

Current requirement at

24 V DC, max.

0.005 A + the current requirement of

motor brake

Max. conductor cross-section 2.5 mm

2

Degree of protection IP20

Dimensions

• Width 68 mm

•Height 63 mm

•Depth 33 mm

Weight, approx. 0.17 kg

Safe Brake Relay

Loading...

Loading...