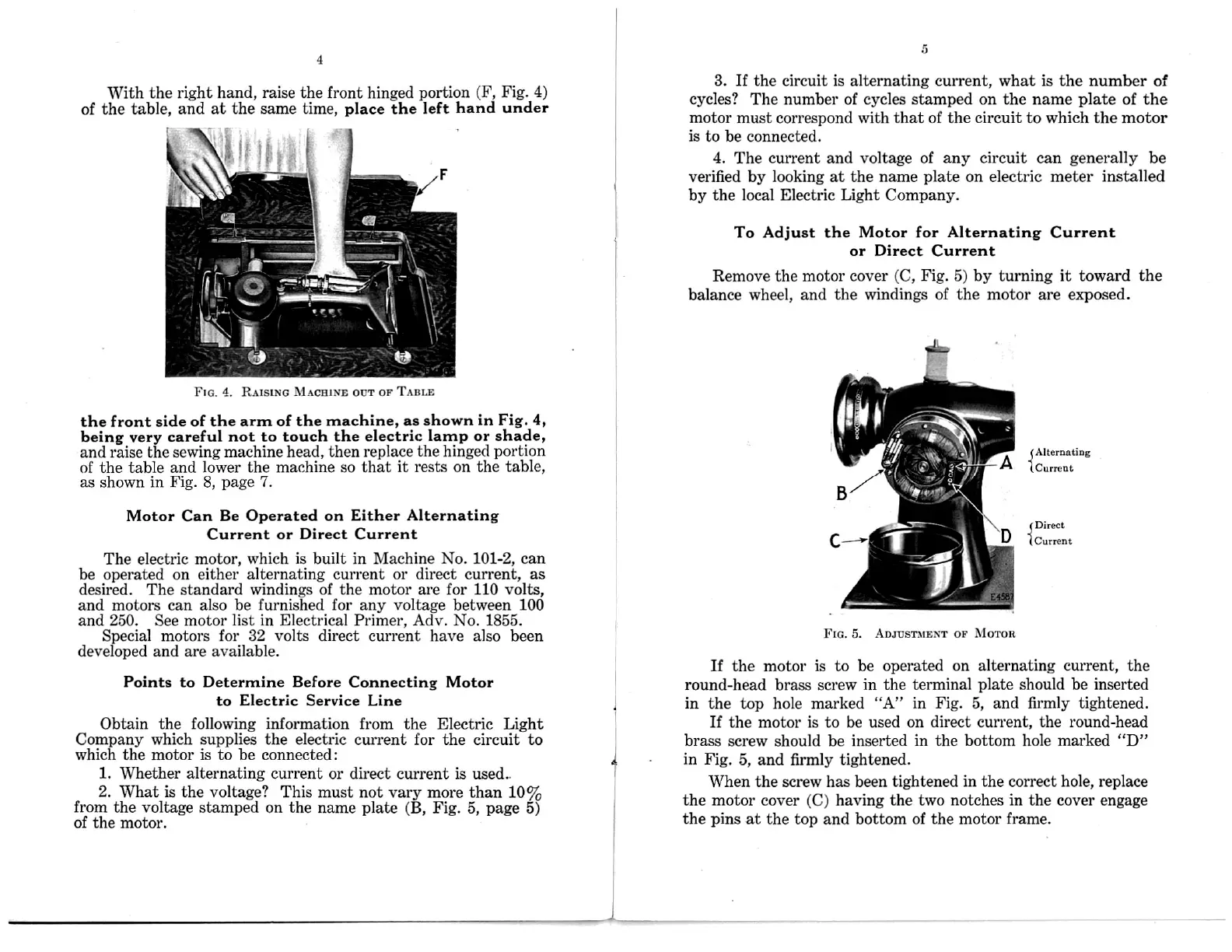

With

the right

hand,

raise

the front hinged portion

(F, Fig. 4)

of the table, and

at the same time, place the

left

hand

under

FIG. or

TABLE

the front side

of the arm

of the machine,

as shown

in Fig. 4,

being very

careful not

to

touch

the electric

lamp or shade,

and

raise the sewing

machine head, then replace

the hinged

portion

of the table and lower the

machine so that it

rests on the table,

as shown in Fig. 8, page

7.

Motor Can Be

Operated on Either

Alternating

Current

or Direct Current

The

electric motor,

which is built in Machine No. 101-2, can

be

operated on either alternating current or

direct current, as

desired.

The standard windings of the motor are for 110 volts,

and motors can

also be furnished for any voltage between 100

and 250. See motor list in Electrical

Primer, Adv. No. 1855.

Special motors for 32 volts direct current have also been

developed and are available.

Points to Determine Before Connecting

Motor

to Electric Service Line

Obtain the following information from the Electric Light

Company which supplies the electric current

for the circuit to

which the motor is to be connected:

1. Whether alternating current or

direct current is used..

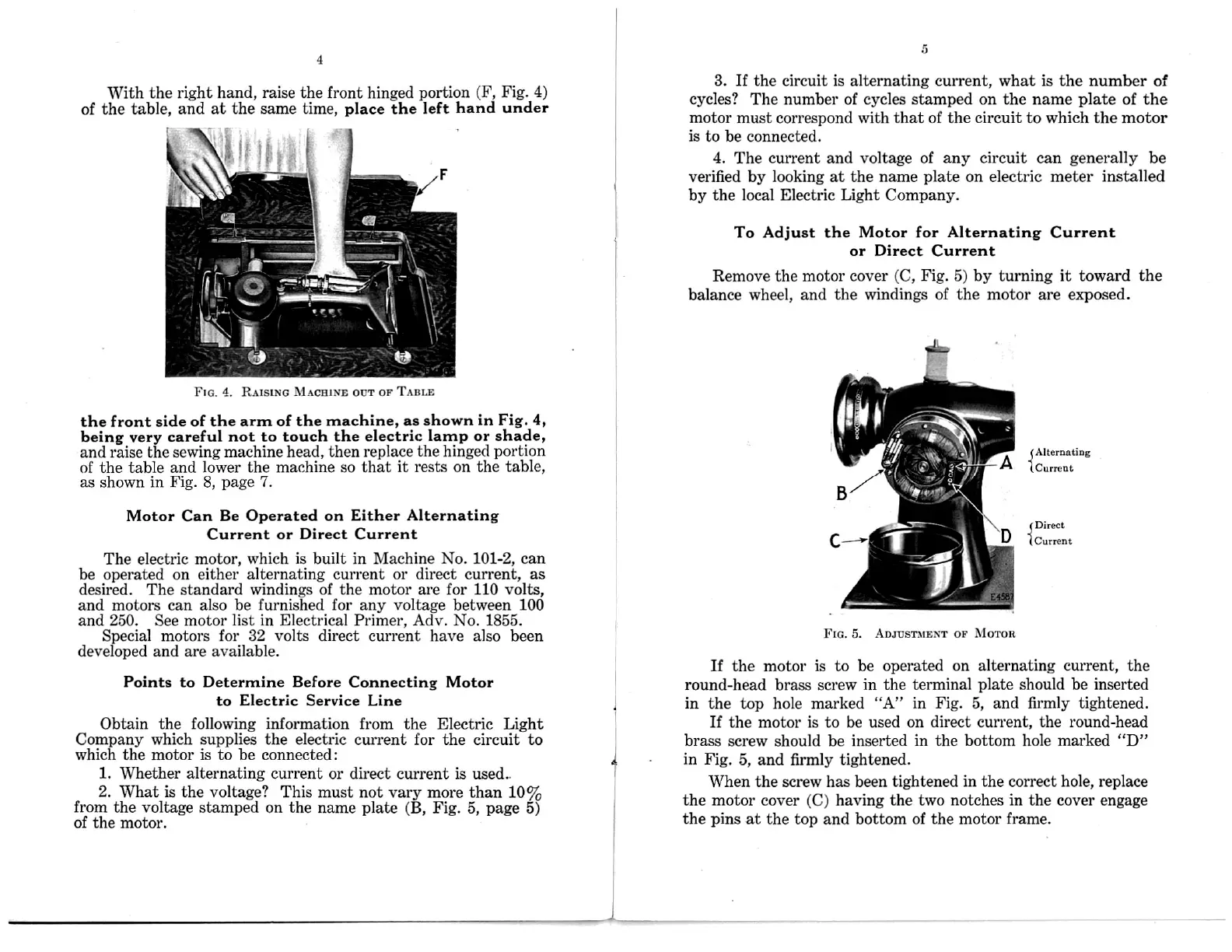

2. What is

the voltage? This must

not vary more than 10%

from

the voltage stamped on the

name plate (B, Fig.

5, page 5)

of the motor.

3. If the circuit is alternating current, what is the number of

cycles?

The number of cycles stamped on the name plate of the

motor must correspond with that of the circuit to which the motor

is to

be connected.

4. The current and voltage of any circuit can generally be

verified by looking at the name plate on electric meter

installed

by the local

Electric Light Company.

To

Adjust the

Motor for Alternating

Current

or Direct

Current

Remove the motor

cover (C, Fig. by turning it toward the

balance wheel, and the

windings of the motor are exposed.

Current

FIG. 5.

or

If the motor is to

be operated on alternating current,

the

round-head

brass screw in

the terminal plate should be inserted

in

the

top

hole marked “A"

in Fig. 5, and firmly tightened.

If the motor is to be used on direct

current, the round-head

brass screw should be inserted in the bottom hole marked

“D”

in Fig.

5, and firmly

tightened.

When the screw has been tightened in the correct hole, replace

the motor cover (C) having the two notches in the cover engage

the pins at the top and bottom of the motor frame.

4

4.

Rusmc MACHiNE our

.')

5)

{Alternating

Current

\D {Direct

ADJUSTMENT

Moron

Loading...

Loading...