TO

SHARPEN

THE

TRIMMER

KNIVES

______________________________________

C,~Se~e~E~igi~dA6

~

--------------------------~--

--

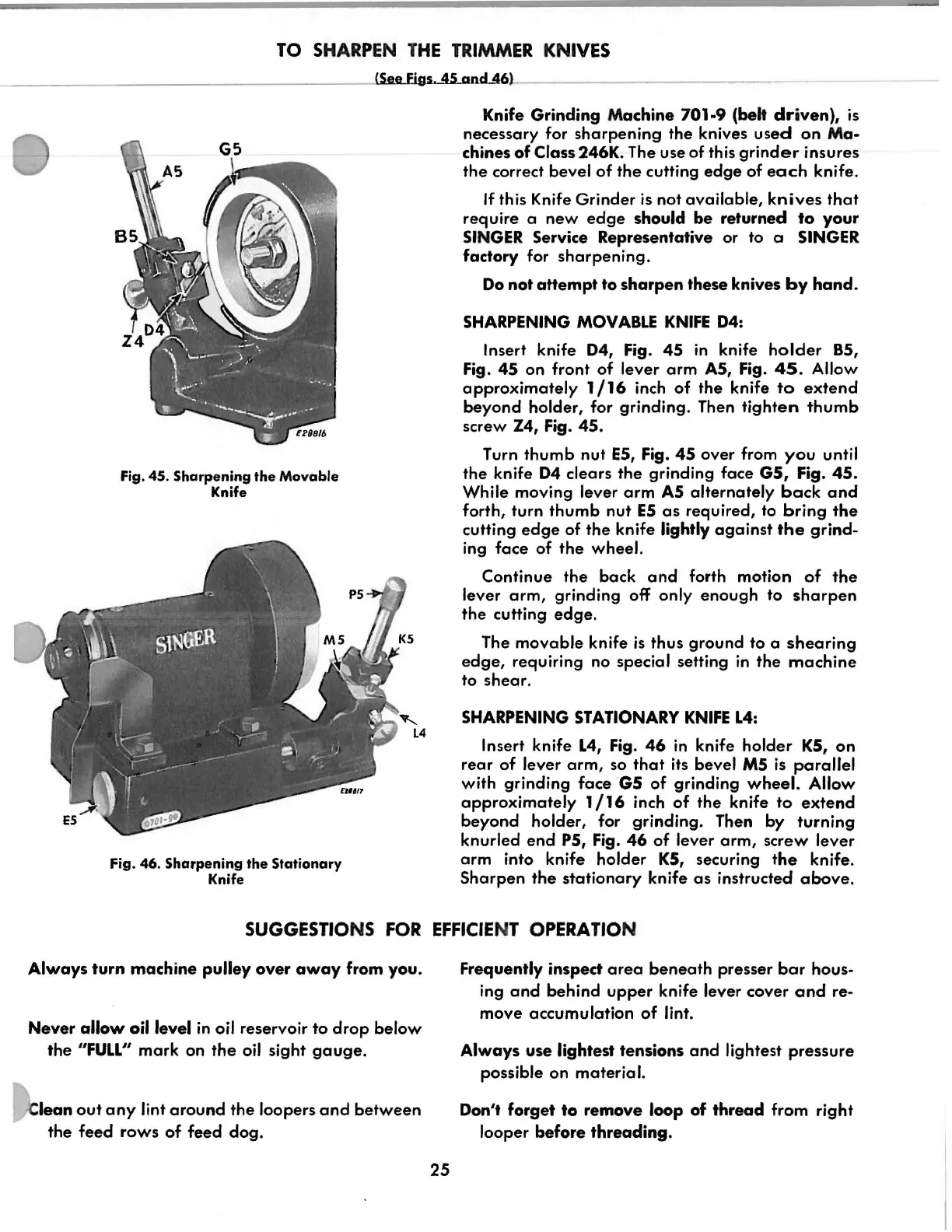

Fig. 45.

Sharpening

the

Movable

Knife

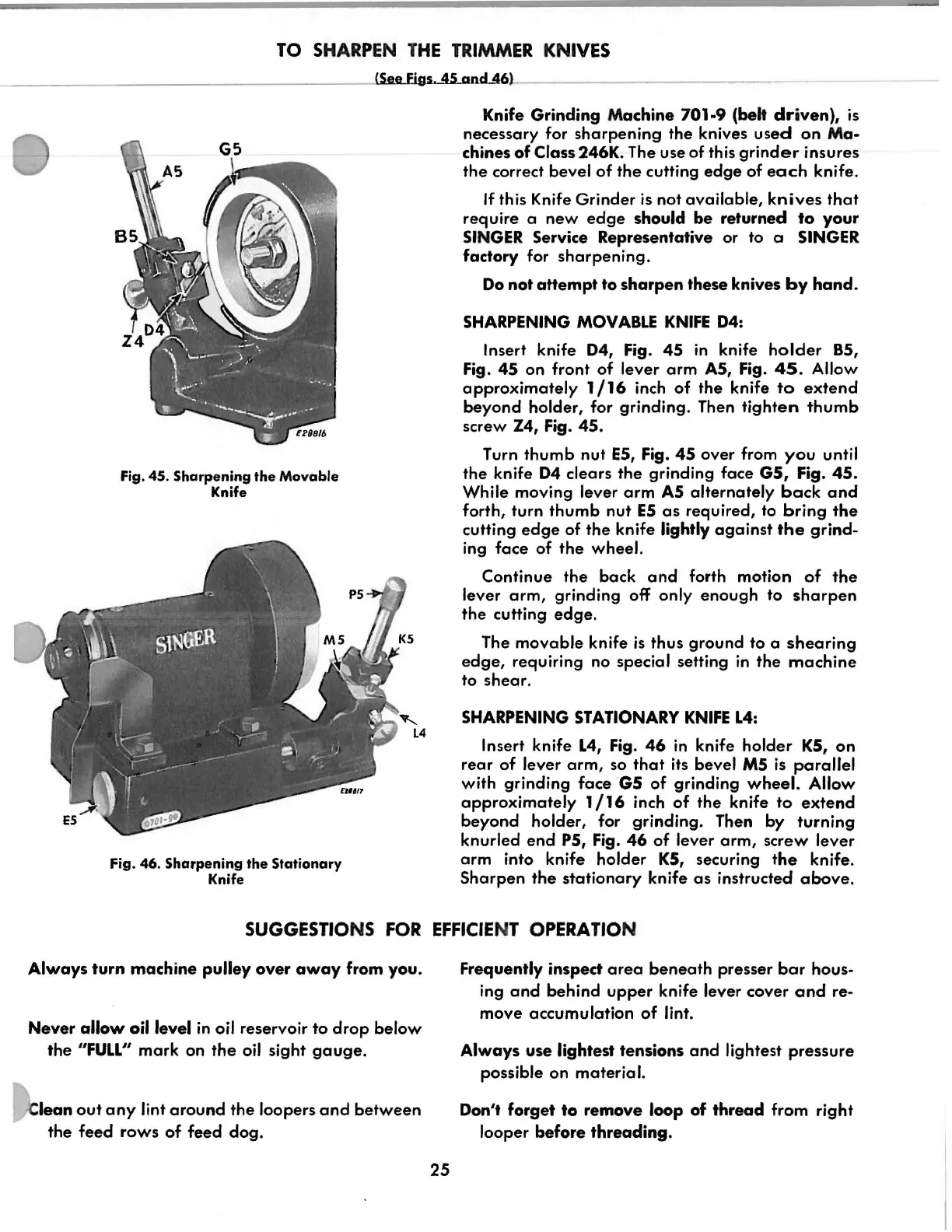

Fig. 46.

Sharpening

the

Stationary

Knife

Knife Grinding Machine

701·9

(belt

driven),

is

necessary for

sharpening

the knives

used

on

Ma·

chines

of

Class 246K. The use of this

grinder

insures

the

correct bevel

of

the

cutting

edge

of

each

knife.

If

this Knife Grinder

is

not

available,

knives

that

require a

new

edge

should

be

returned

to

your

SINGER

Service Representative or to a SINGER

factory for

sharpening.

Do

not

attempt

to

sharpen

these knives

by

hand.

SHARPENING

MOVABLE

KNIFE

D4:

Insert knife D4, Fig. 4S

in

knife

holder

BS,

Fig. 4S on front

of

lever

arm

AS, Fig.

45.

Allow

approximately

1/16

inch

of

the

knife

to

extend

beyond

holder, for grinding. Then

tighten

thumb

screw Z4, Fig. 4S.

Turn

thumb

nut

ES,

Fig.

4S

over from

you

until

the

knife

D4

clears

the

grinding face

GS,

Fig.

4S.

While moving lever

arm

AS

alternately

back

and

forth, turn

thumb

nut

ES

as

required, to

bring

the

cutting

edge

of

the knife lightly

against

the

grind-

ing

face

of

the

wheel.

Continue

the

back

and

forth motion

of

the

lever

arm,

grinding off only

enough

to

sharpen

the cutting

edge.

The

movable

knife

is

thus ground to a

shearing

edge,

requiring no special setting

in

the

machine

to

shear.

SHARPENING

STATIONARY

KNIFE

L4:

Insert knife

L4,

Fig.

46

in

knife holder

KS,

on

rear

of

lever

arm,

so

that

its bevel

MS

is

parallel

with grinding

face

GS

of

grinding

wheel.

Allow

approximately

1

/16

inch

of

the

knife

to

extend

beyond

holder, for grinding. Then by

turning

knurled

end

PS, Fig.

46

of

lever

arm,

screw lever

arm

into knife holder

KS,

securing

the

knife.

Sharpen

the

stationary

knife

as

instructed

above.

SUGGESTIONS

FOR

EFFICIE

NT

OPERATION

Always

turn

machine

pulley

over

away

from you.

Never

allow

oil level

in

oil reservoir

to

drop

below

the

11

FULL''

mark

on

the

oil sight

gauge

.

lean

out

any

lint

around

the

loopers

and

between

the

feed

rows

of

feed

dog.

25

Frequently inspect

area

beneath

presser

bar

hous-

ing

and

behind

upper

knife lever cover

and

re-

move

accumulation

of

lint.

Always

use

lightest

tensions

and

lightest

pressure

possible on material.

Don't

forget

to

remove

loop

of

thread

from right

looper

before

threading.

From the library of: Superior Sewing Machine & Supply LLC

Loading...

Loading...