Bobbin Winder Replacement & Adjustment: (continued)

wrapped around the underneath part. Note that some of these units will

hav

don

9.

10.

art will insert itself into the center post of the bobbin

11. read is wrapped lint

12.

13.

17.

19.

ow.

20. th

w.

e

ak

ed a

g

s

it

ill

is r

ll add the Bobbin Winder document that was provided as a standalone

document, at the end of this manual. Go ahead and return the Hook Removal Section, next page, bullet 11.

Clean the unit all up, and ensure no threads are

e a little plastic washer, don’t loose it, and don’t damage it during cleaning. Others may not, so if yours doesn’t,

’t worry about it.

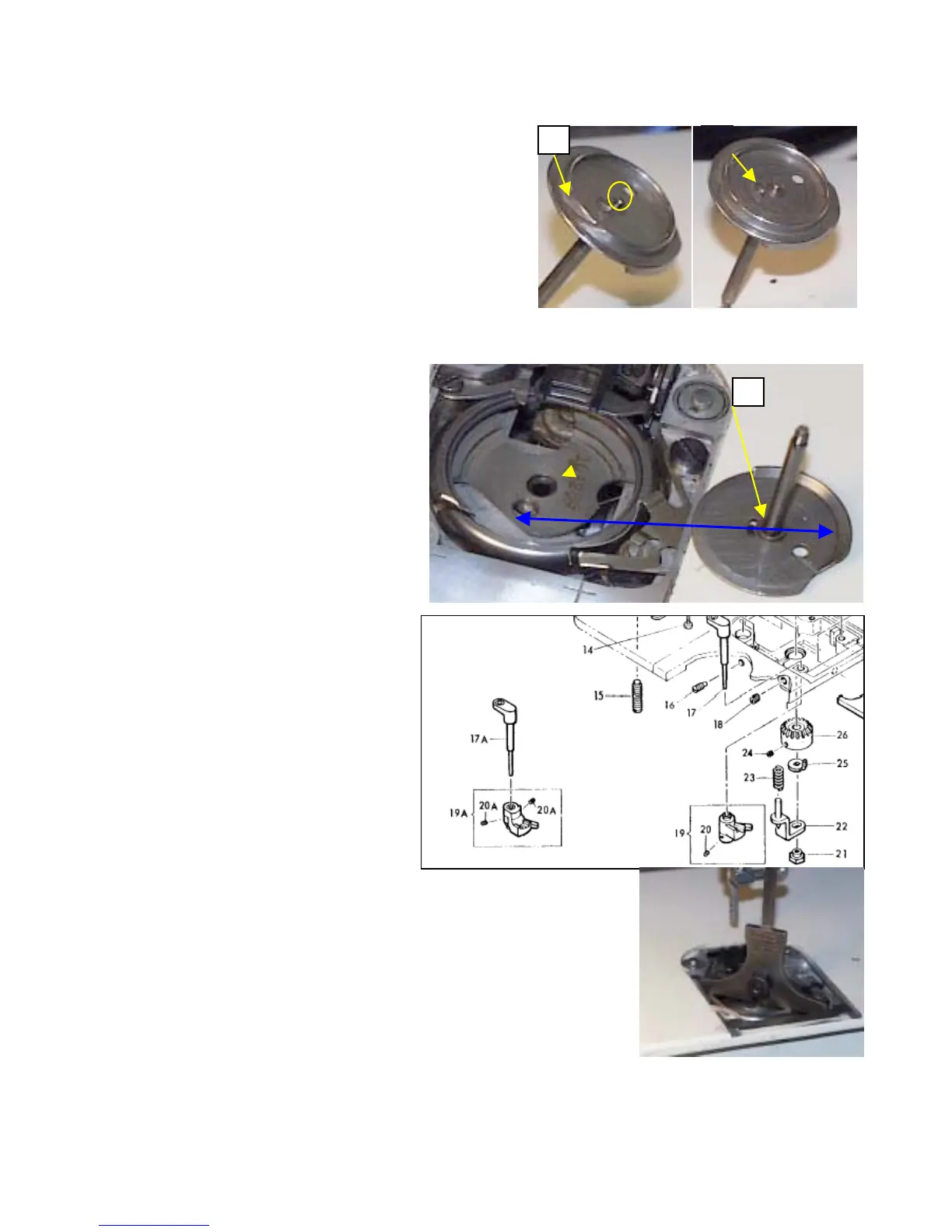

We want to inspect the thread cut off, and ensure it isn’t

broken, or damaged. Yellow arrow, Fig 1. It should

appear as shown. Now I don’t know of a way to sharpen

it, and ideally it is pretty much maintenance free.

We also want to inspect the driver tab that engages the

bobbin. Yellow arrow, Fig 2. Just ensure it isn’t

broken, or has been bent downward. Generally, it

should just fine. Also inspect the bobbin-centering pin.

Yellow circle. Ensure it hasn’t been flattened out. This

1

p

when winding.

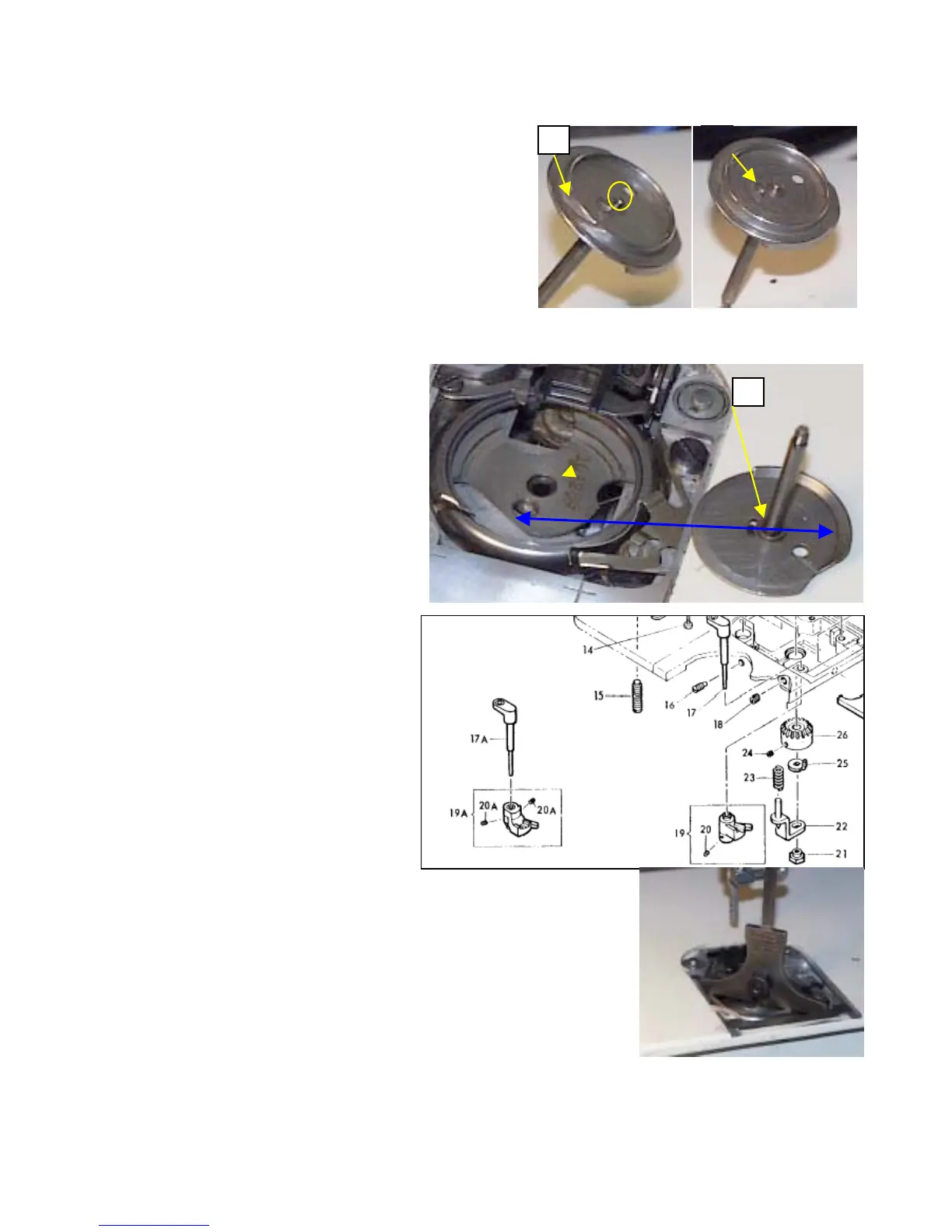

As mentioned before bullet 9, ensure no th

stuck inside the hook area. Fig 3,

yellow arrows.

Go ahead and clean up the other

bobbin winder parts. Then inspect for

thread underneath the hook. If you

need to remove the hook, go ahead and

around the shaft, and you don’t have any thread, or

3

skip to that section, and we’ll return to

this part for installing the hook driver.

Note before you install the hook

driver, that it only fits back into the

machine two ways, but only one is

correct. And that is with it seated

down as far as it’ll go. Note the items

shown by the blue arrows, it fits this

way correctly.

14. Reinstall the spring, item 23

15. Reinstall the positioner, item 25. Do

not that the hook driver has a notched

area that this part must fit onto

properly before tightening up the nut.

16. Reinstall item 22

Reinstall item 21, the lock nut. Don’t

wrench it down, just good and snug.

18. Ensure the unit moves up and down

freely. Do this by pushing up on item

22, where the lift cam, item 19, or

19A would fit.

Reinstall item 17, or 17A. Also

ensure the part is broken, or have any

cracks in the plastic. If so, replace it n

Reinstall item 19, or 19A. Also ensure

e it no

e part is broken, or have any

The crack is most noticeable

stment will not remain

r failure. Just install the lift

e contact with item 22.

depth gauge here. Lets adjust

you’ll have to repeat it a few

e to approximately 5/64 to

shown, and activate the lever.

h the depth gauge. Adjust until

it correct, and all the parts are in good condition, along with either a good

wind correctly at the point. The depth gauge has to lay flat across the

from a 600, on the 700, you’ll need to position the gauge across the othe

cracks in the plastic. If so, replac

in the plastic sleeve. If it is cracked, adju

accurate, and you will have bobbin wind

cam on the lever, until it just starts to m

21. Now for the tricky part, and you do ne

for proper lift height, and more than likely

times before it is right. Set the depth gau

3/16 of an inch. Place the depth gauge a

The hook drive will just make contact w

you achieve the proper lift. If you have

bobbin, or new bobbin – preferred, it w

surface of the hook. The picture shown

way, by the lever and thread pull off. I’

Loading...

Loading...