From the library of Superior Sewing Machine & Supply LLC - www.supsew.com

40

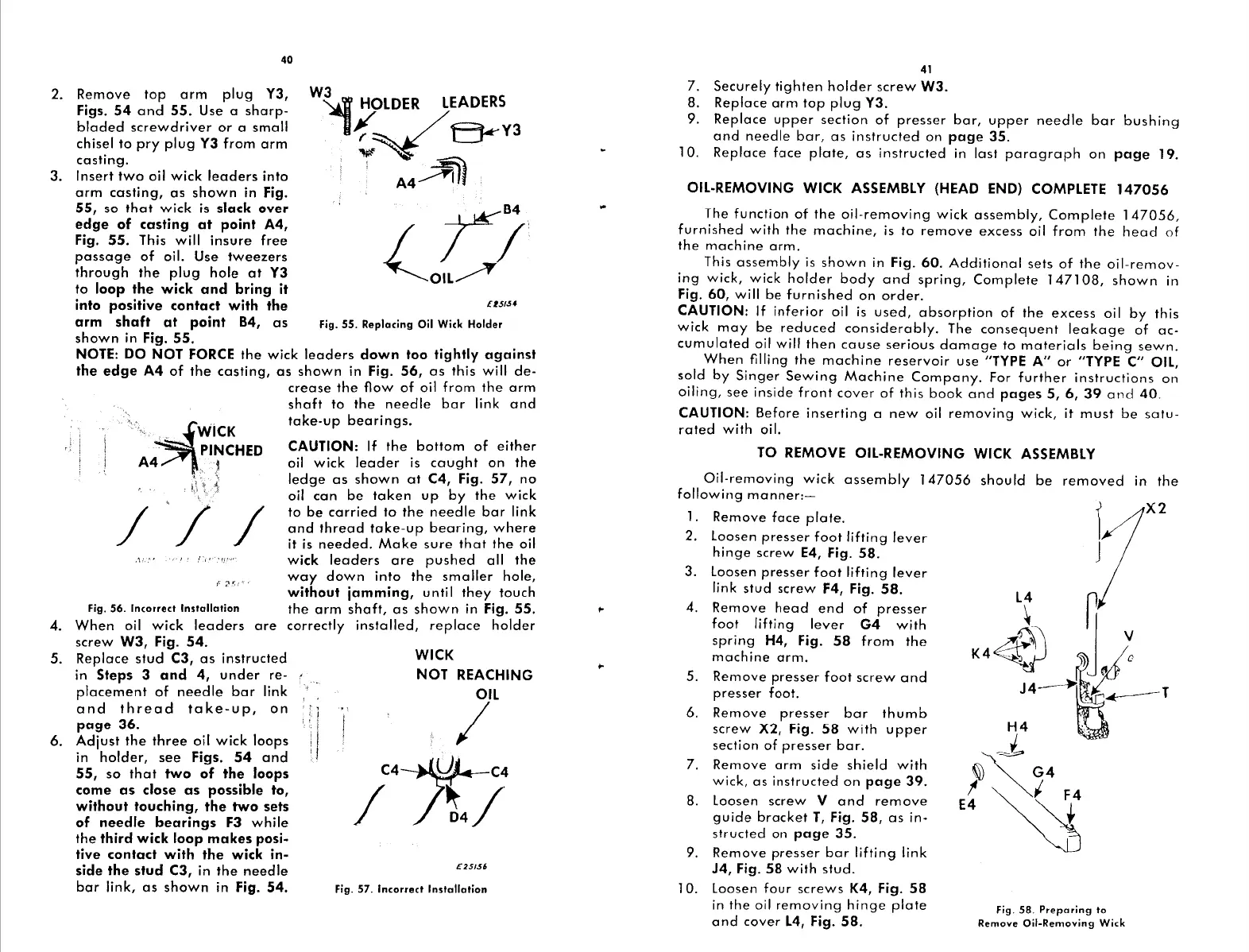

2.

Remove

top

arm

plug

Y3,

Figs.

54

and

55.

Use a

sharp-

bladed

screwdriver

or

a

small

chisel

to

pry

plug

Y3

from

arm

casting.

3.

Insert

two

oil

wick

leaders

into

arm

casting,

as

shown

in

Fig.

55,

so

that

wick

is

slack over

edge of casting

at

point A4,

Fig. 55.

This will

insure

free

passage

of

oil. Use

tweezers

through

the

plug

hole

at

Y3

to

loop the wick

and

bring it

W~

HOLDER

LEADERS

lt~E}<-Y3

i:

A4~

r

B4

I

I

'OIL~

into positive contact with the

u

5

,~•

arm shaft

at

point

B4,

as

Fig.

55.

Replacing

Oil Wick

Holder

shown

in

Fig. 55.

NOTE: DO

NOT

FORCE

the

wick

leaders

down

too tightly against

the edge

A4

of

the

casting,

as

shown

in

Fig. 56,

as

this

will

de-

crease

the

flow

of

oil

from

the

arm

shaft

to

the

needle

bar

link

and

-~WICK

PINCHED

take-up

bearings.

A4

l

'

'

Fig.

56.

Incorrect

Installation

4.

When

oil

wick

leaders

are

screw

W3,

Fig. 54.

CAUTION:

If

the

bottom

of

either

oil

wick

leader

is

caught

on

the

ledge

as

shown

at

C4, Fig. 57,

no

oil

can

be

taken

up

by

the

wick

to

be

carried

to

the

needle

bar

link

and

thread

take-up

bearing,

where

it is

needed.

Make

sure

that

the

oil

wick

leaders

are

pushed

all

the

way

down

into

the

smaller

hole,

without

jamming,

until

they

touch

the

arm

shaft,

as

shown

in

Fig. 55.

correctly

installed,

replace

holder

5.

Replace

stud

C3,

as

instructed

in

Steps

3

and

4,

under

re-

placement

of

needle

bar

link

and

thread

take-up,

on

page 36.

6.

Adjust

the

three

oil

wick

loops

in

holder,

see

Figs.

54

and

55,

so

that

two

of

the loops

come

as

close

as

possible to,

without touching, the two

sets

of needle bearings

F3

while

the

third wick loop makes posi-

tive contact

with

the wick in-

side the stud C3,

in

the

needle

bar

link,

as

shown

in

Fig. 54.

WICK

NOT

REACHING

OIL

I

;·JV

£25156

Fig.

57.

Incorrect

Installation

...

41

7.

Securely

tighten

holder

screw

W3.

8.

Replace

arm

top

plug

Y3.

9.

Replace

upper

section

of

presser

bar,

upper

needle

bar

bushing

and

needle

bar,

as

instructed

on

page 35.

l 0.

Replace

face

plate,

as

instructed

in

last

paragraph

on

page

19.

OIL-REMOVING WICK ASSEMBLY (HEAD END) COMPLETE

147056

The

function

of

the

oil-removing

wick

assembly,

Complete

147056,

furnished

with

the

machine,

is

to

remove

excess

oil

from

the

head

of

the

machine

arm.

This

assembly

is

shown

in

Fig. 60.

Additional

sets

of

the

oil-remov-

ing

wick,

wick

holder

body

and

spring,

Complete

147108,

shown

in

Fig. 60,

will

be

furnished

on

order.

CAUTION:

If

inferior

oil

is

used,

absorption

of

the

excess

oil

by

this

wick

may

be

reduced

considerably.

The

consequent

leakage

of

ac-

cumulated

oil will

then

cause

serious

damage

to

materials

being

sewn.

When

filling

the

machine

reservoir

use

"TYPE

A"

or

"TYPE

C"

OIL,

sold

by

Singer

Sewing

Machine

Company.

For

further

instructions

on

oiling,

see

inside

front

cover

of

this

book

and

pages 5, 6,

39

and

40.

CAUTION:

Before

inserting

a

new

oil

removing

wick,

it

must

be

satu-

rated

with

oil.

TO REMOVE OIL-REMOVING WICK ASSEMBLY

Oil-removing

wick

assembly

147056

should

be

removed

in

the

following

manner:-

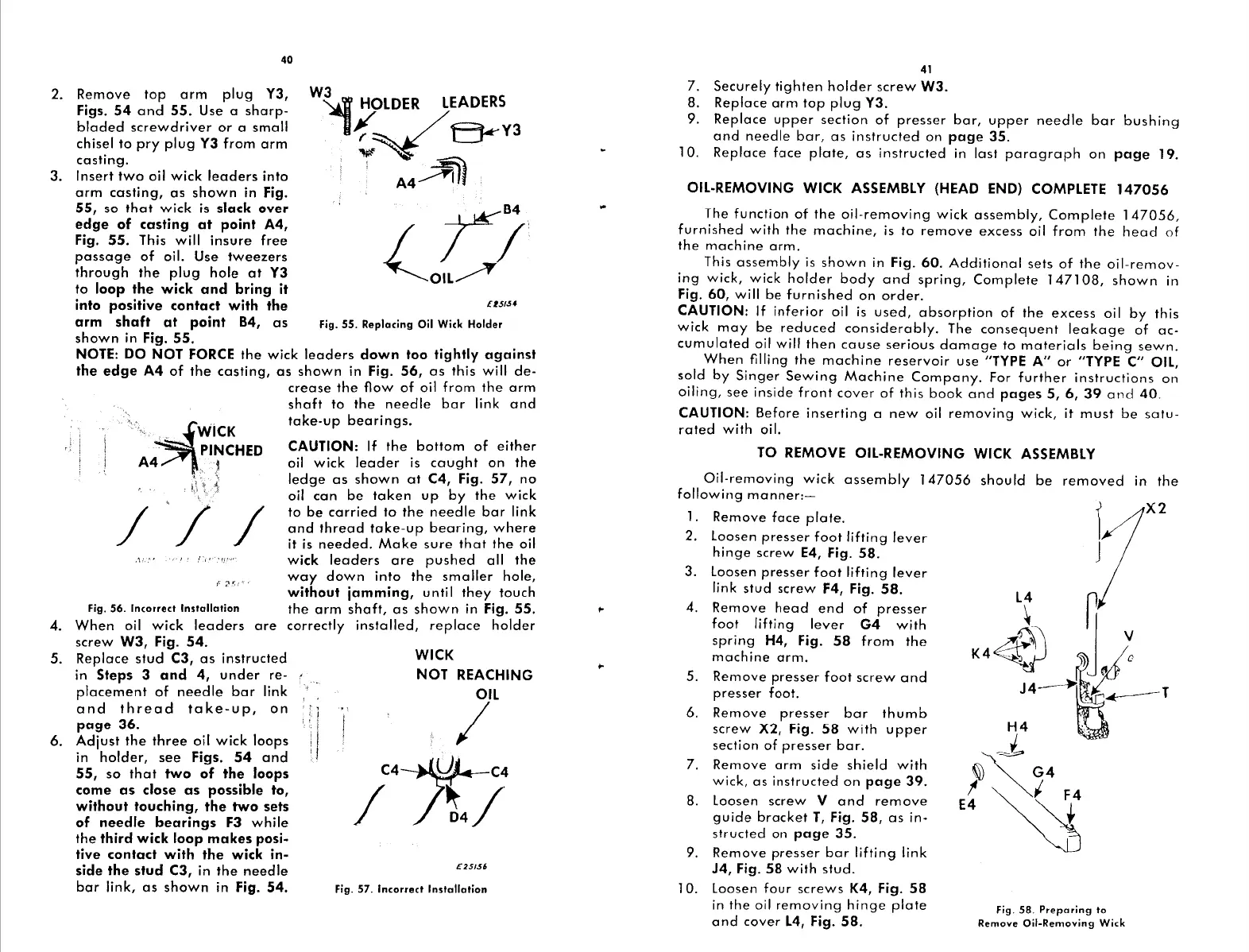

].

Remove

face

plate.

2. Loosen

presser

foot

lifting

lever

hinge

screw

E4,

Fig. 58.

3. Loosen

presser

foot

lifting

lever

link

stud

screw

F4, Fig.

58.

4.

5.

6.

7.

8.

9.

10.

Remove

head

end

of

presser

foot

lifting

lever

G4

with

spring

H4, Fig.

58

from

the

machine

arm.

Remove

presser

foot

screw

and

presser

foot.

Remove

presser

bar

thumb

screw

X2,

Fig. 58

with

upper

section

of

presser

bar.

Remove

arm

side

shield

with

wick,

as

instructed

on

page

39.

Loosen

screw

V

and

remove

guide

bracket

T,

Fig. 58,

as

in-

structed

on

page

35.

Remove

presser

bar

lifting

link

J4, Fig. 58

with

stud.

Loosen

four

screws

K4, Fig. 58

in

the

oil

removing

hinge

plate

and

cover

L4,

Fig. 58.

t

X2

J

Lt

n

i~

V

J

4~

_

..--T

H4

°'

~

ij

G4

I

~(~4

E4

~1

Fig.

58.

Preparing

lo

Remove

Oil-Removing

Wick

Loading...

Loading...