LIFTING

SCREW

LIFTING

BRACKET

Fig.

23« Setting

the

Feed

Roll

•••.

•

CEtfTERED

IN.-.r"

/®

NEEDLE

HOLE

0"""

®

4 -

I.//

/V

CENTERED IN

if

NEEDLE

HOLE

^

Fig.

24.

Centralizing

the

Needles

SETTING

THE

FEED

ROLL

AT

CORRECT

HEIGt

;|IACHINE

262.20

AND

262-32^^^ggg^^^||

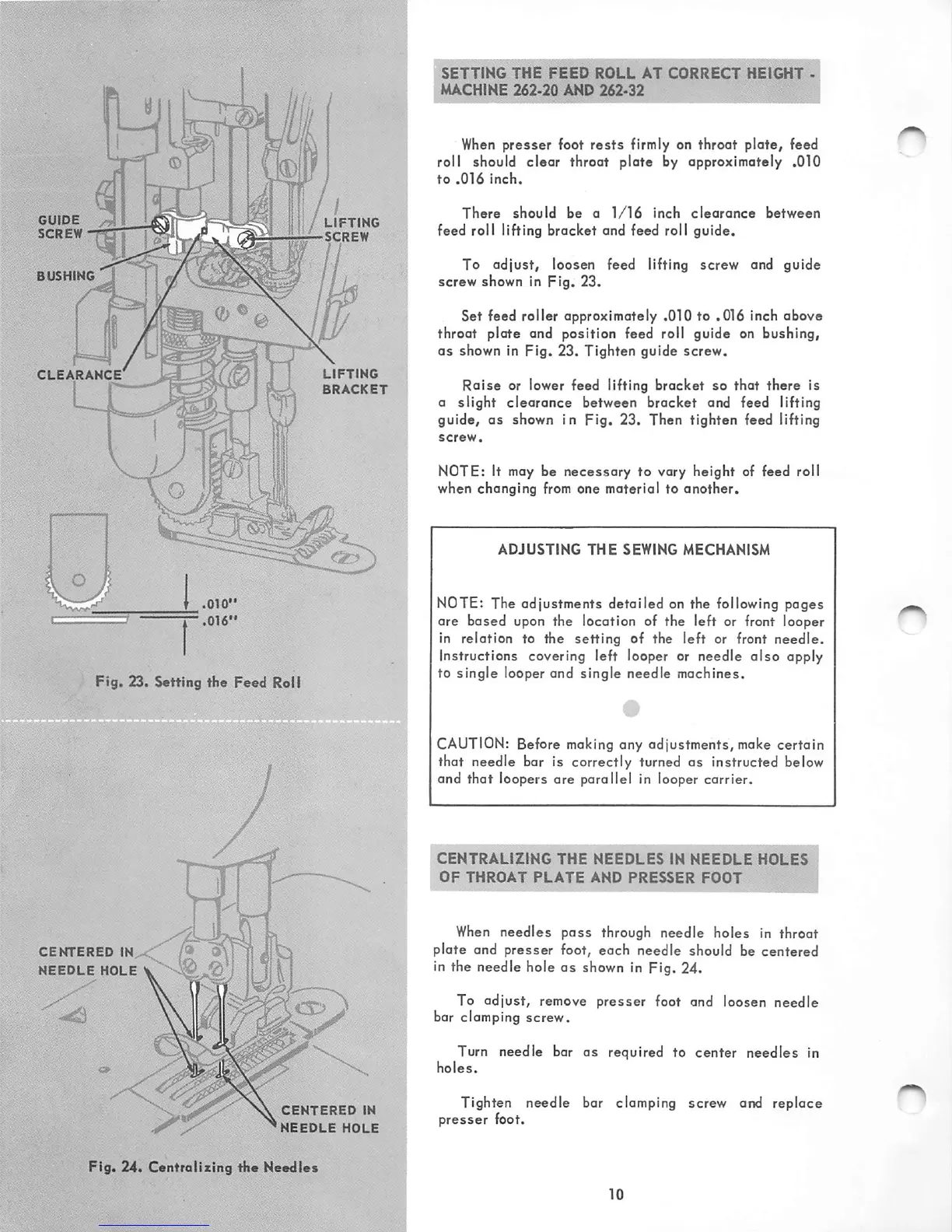

When

presser foot

rests

firmly on throat plate, feed

roll should cleor throat plate by approximotely .010

to

.016

inch.

There

should

be

a

1/16

Inch

clearance

between

feed roll lifting bracket and feed roll guide.

To adjust, loosen feed lifting screw and guide

screw shown In Fig. 23.

Set feed roller approximately .010 to .016 inch above

throat plate and position feed roll guide on bushing,

as shown in Fig. 23. Tighten guide screw.

Raise

or lower feed lifting bracket so

that

there is

a slight clearonce between bracket and feed lifting

guide,

as

shown in

Fig.

23. Then

tighten

feed lifting

NOTE: it may be necessary to vary height of feed rol

when changing from one material to

another.

ADJUSTING

THE

SEWING

MECHANISM

NOTE: The adjustments detailed on the following pages

ore based upon the location of the left or front looper

in relation to the

setting

of the left or front

needle.

Instructions covering left looper or needle

also

apply

to

single

looper and

single

needle machines.

CAUTION: Before making any adjustments, make certain

that needle bar is correctly turned as Instructed below

and

that

ioopers

are

parallel in looper carrier.

CENTRALIZING

THE

NEEDLES

IN

NEEDLE

HOLEI

OF

THROAT

PLATE

AND

PRESSER

FOOT

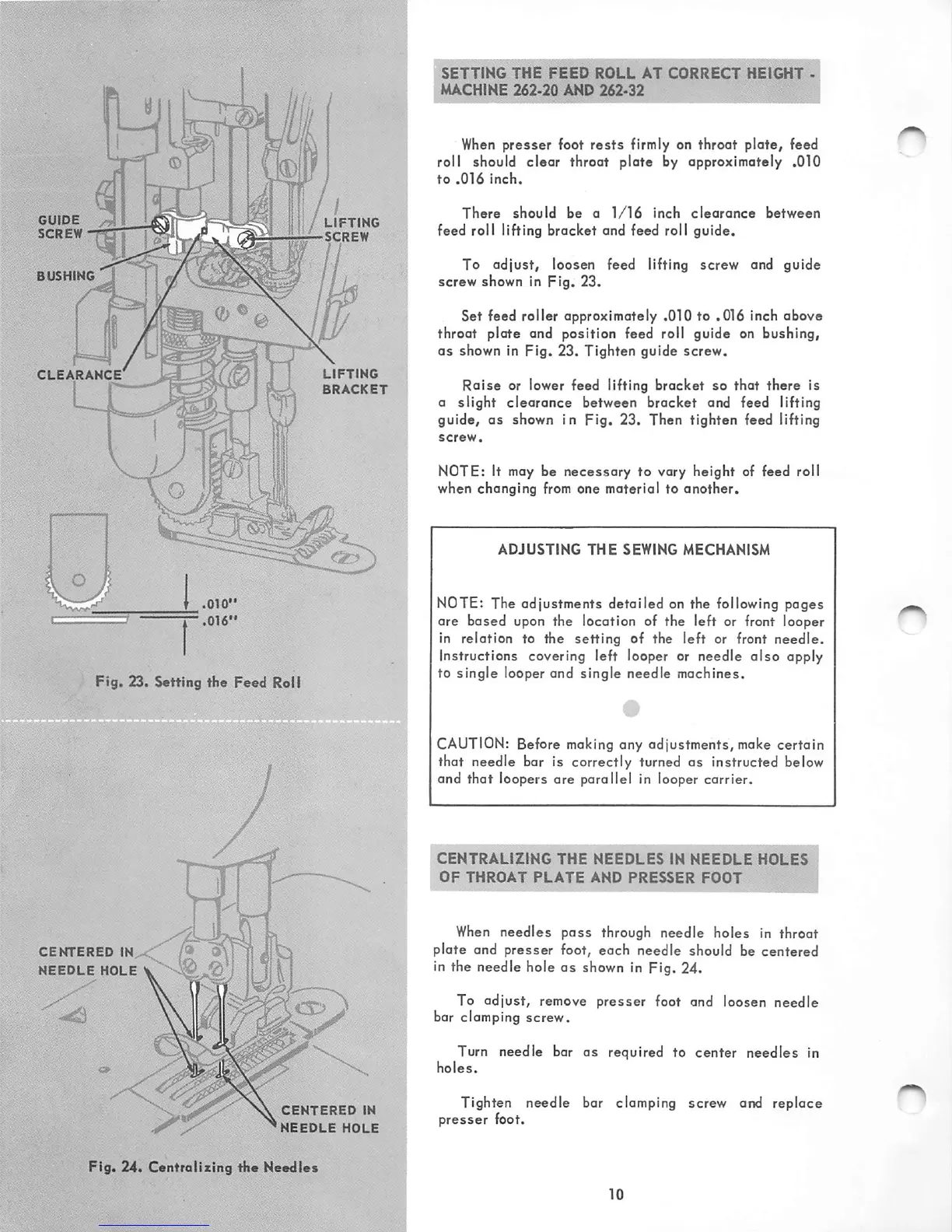

When

needles pass through needle holes in throat

plate and

presser

foot,

each

needle should be

centered

in the needle hole as shown in Fig. 24.

To

adjust,

remove

presser

foot and loosen

needle

bar clamping

screw.

Turn needle bar

as

required to

center

needles

in

holes.

Tighten needle bar clamping screw and replace

presser

foot.

Loading...

Loading...