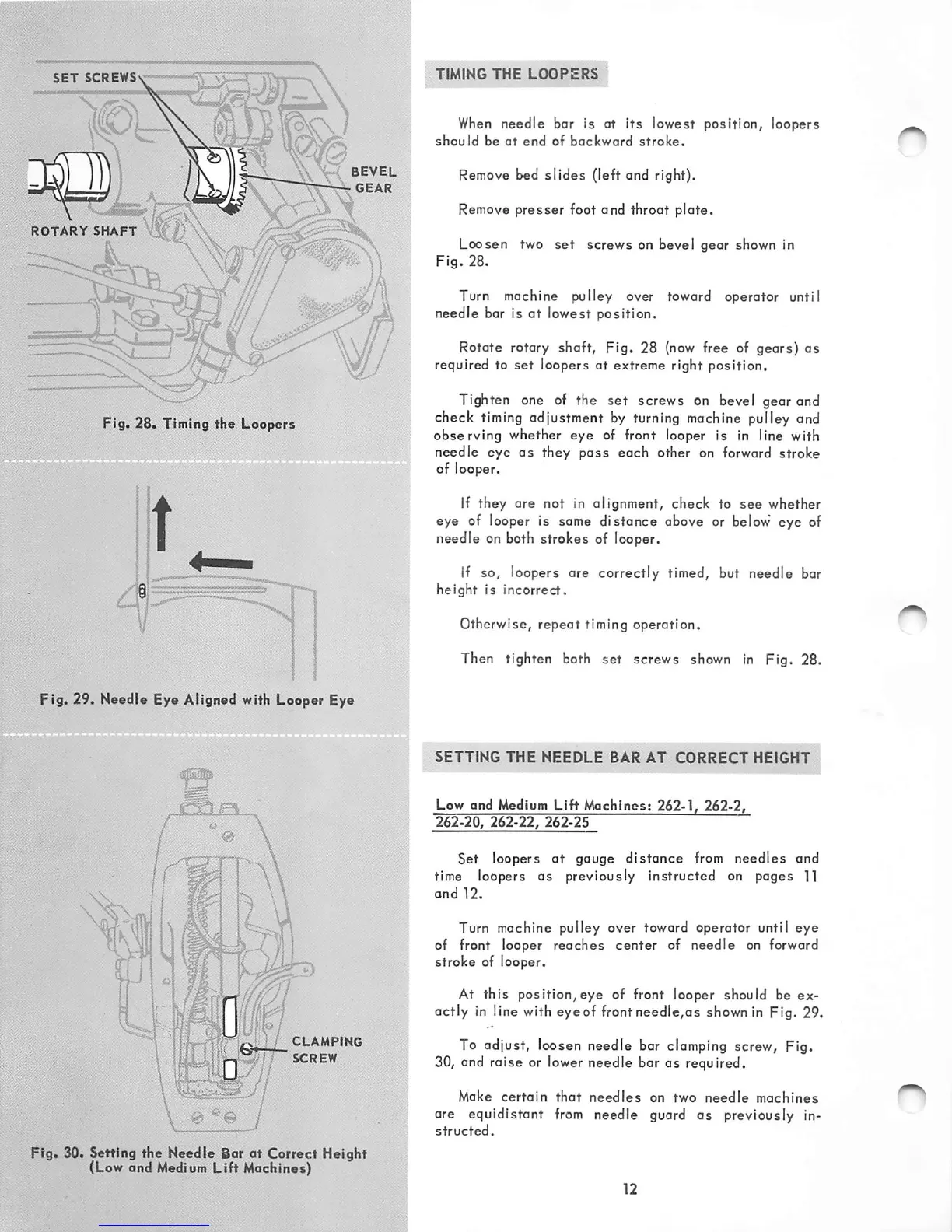

SET

SCREWSv

—

::Vr.-'

M

" ,

p.

ROTARY

SHAFT

Fig.

28.

Timing

the

Loopers

BEVEL

GEAR

—"v-A

"r3

W-

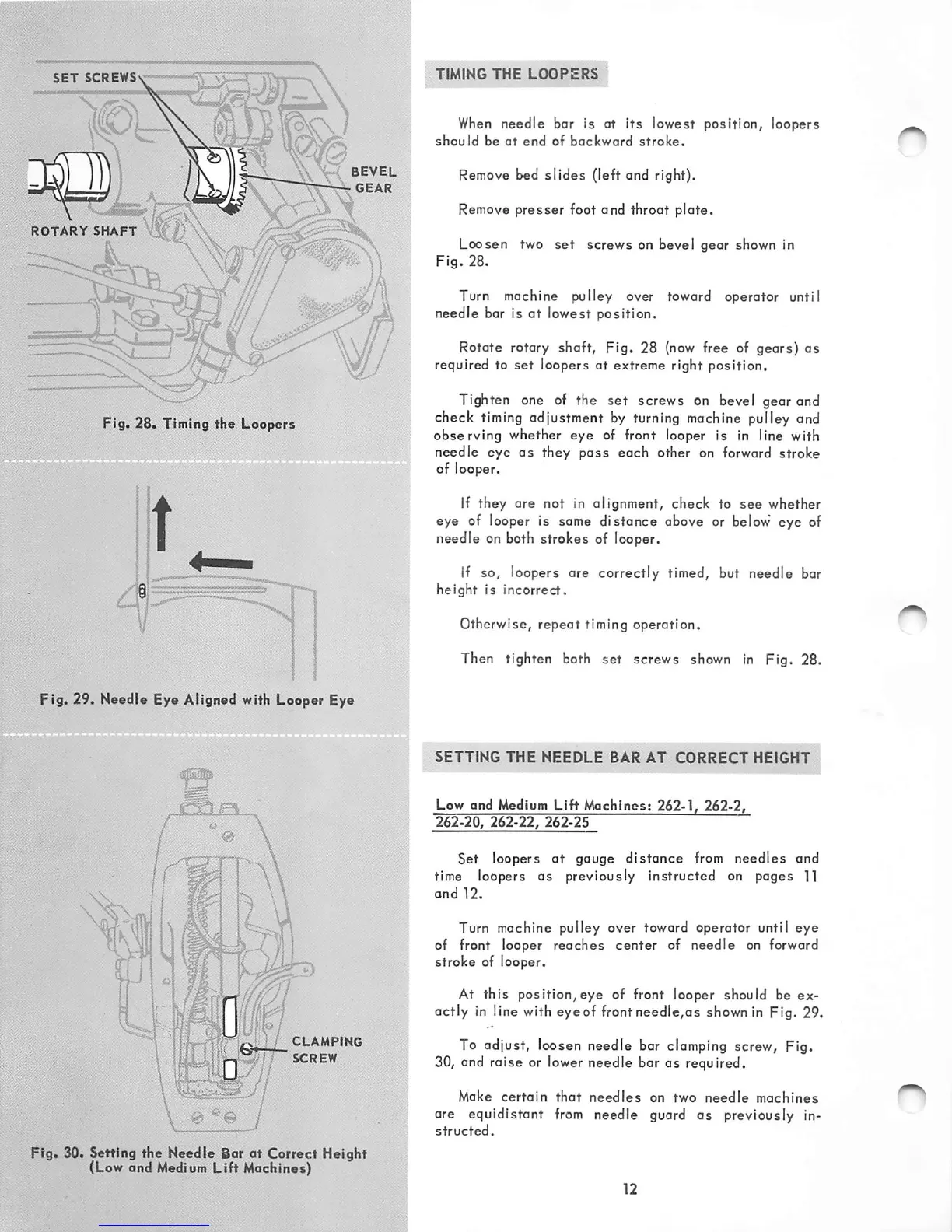

Fig. 29. Needle Eye Aligned with Looper Eye

' /

CLAMPING

\ f //

SCREW

Fig. 30. Setting

the

Needle Bor

at

Correct Height

(Low and

Medium

Lift Machines)

TIMING

THE

LOOPERS

When

needle bar is at its lowest position, loopers

should

be

at

end

of

backward

stroke.

Remove bed

slides

(left and right).

Remove

presser

foot and throat

plate.

Loosen two

set

screws on bevel gear shown in

Fig.

28.

Turn machine pulley over toward operator until

needle bar is at lowest position.

Rotate rotary shaft, Fig, 28

(now

free of gears) as

required to

set

loopers at extreme right position.

Tighten one of the

set

screws on bevel gear and

check timing adjustment by turning machine pulley and

observing

whether

eye

of front looper is in line with

needle eye as they pass each other on forward stroke

of looper.

If they ore not in alignment, check to

see

whether

eye of looper is some

distorKre

above or below eye of

needle on both

strokes

of looper.

if so, loopers are correctly timed, but needle bar

height is incorrect.

Otherwise, repeat timing operation.

Then tighten both set screws shown in Fig. 28.

SETTING

THE

NEEDLE

BAR

AT

CORRECT

HEIGHT

Low

and

Medium

Lift

Machines:

262-1,

262-2,

262-20,

262-22,

262-25

Set loopers at gouge

distance

from needles and

time loopers as previously instructed on pages 11

and

12.

Turn machine pulley over toward operator until

eye

of front looper

reaches

center

of needle on forward

stroke of looper.

At

this

position,eye

of front looper should be ex

actly in line with eyeof front needle,as shown in Fig. 29.

To adjust, loosen needle bar clamping screw. Fig.

30, and raise or lower needle bar as required.

Make

certain

that

needles

on two

needle

machines

are equidistant

from

needle

guard

as previously in

structed.

Loading...

Loading...