SETTING

THE

STATIONARY

NEEDLE

GUARD

When

needles

and loopers are correctly

set

in re

lation to each other, they should

pass

one another as

closely as possible without touching.

Function of

stationary

needle guard is to prevent

needles

from being sprung into path of loopers when

loopers are on forward

stroke.

Check

needles

to

see

that

they are not bent, worn

or damaged.

NOTE: On two

and

three

needle

machines,

all

needles

should be the same

distance

from

needle

guard.

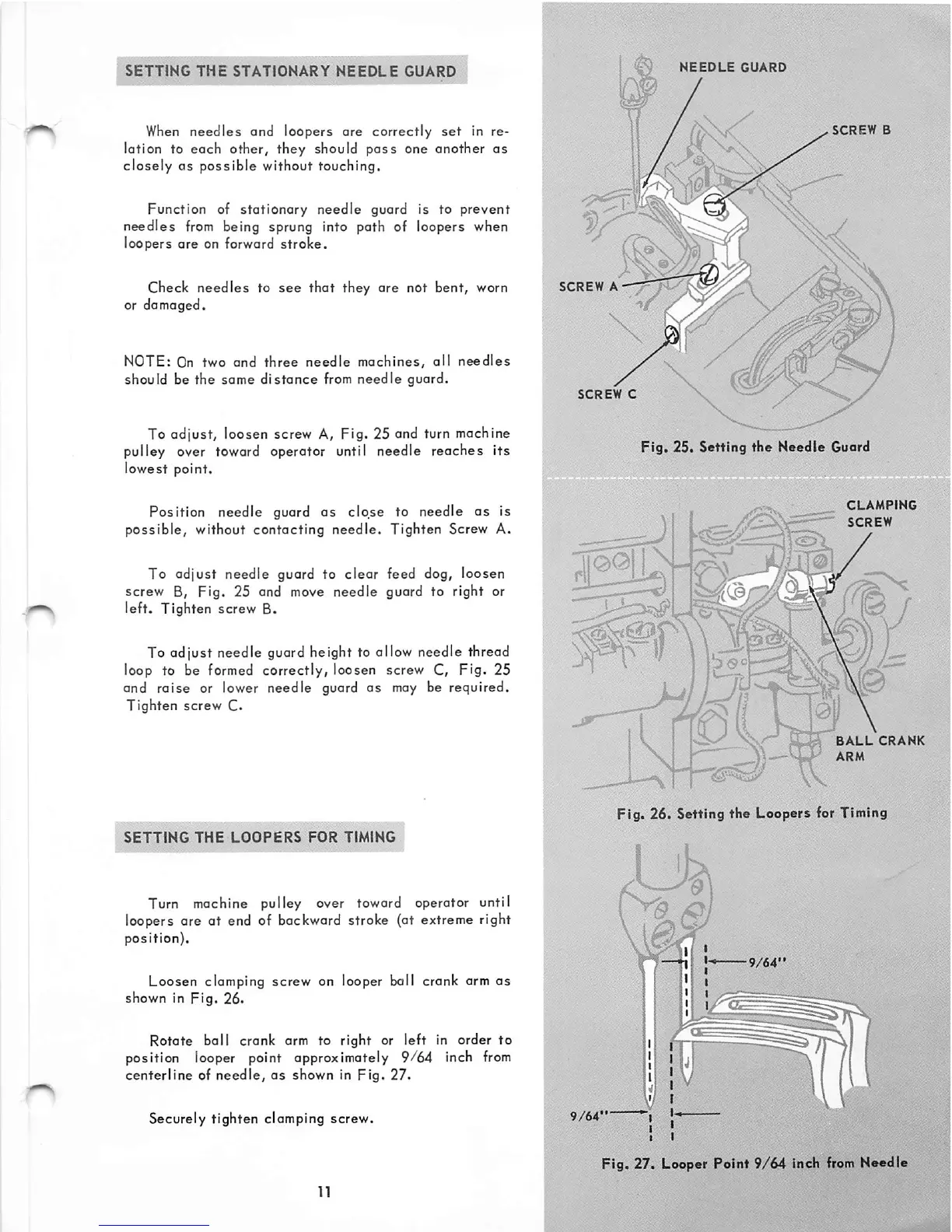

To adjust, loosen screw A, Fig. 25 and turn machine

pulley over toward operator until needle reaches

its

lowest point.

Position needle guard as close to needle as is

possible,

without

contacting

needle.

Tighten Screw A.

To adjust needle guard to clear feed dog, loosen

screw B, Fig. 25 and move needle guard to right or

left. Tighten screw B.

To adjust needle guard height to allow needle thread

loop to be formed correctly, loosen screw C, Fig. 25

and

raise

or lower needle guard

as

may be required.

Tighten screw C.

SETTING

THE

LOOPERS

FOR

TIMING

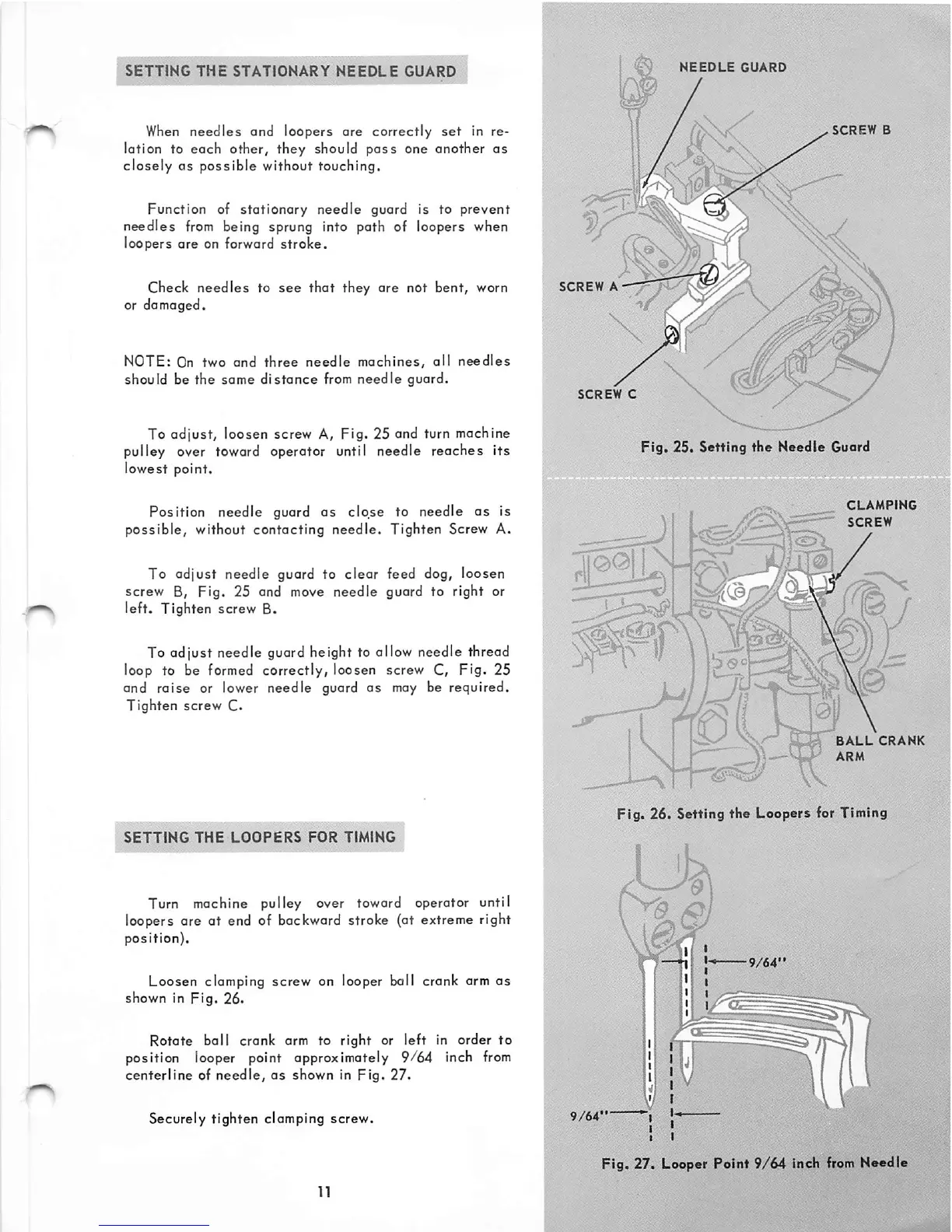

Turn machine pulley over toward operator until

loopers are at end of backward stroke (at extreme right

position).

Loosen clamping screw on looper ball crank arm as

shown in

Fig.

26.

Rotate ball crank arm to right or left in order

to

position looper point approximately

9/64

inch

from

centeriine

of

needle,

as shown in Fig. 27.

Securely tighten clamping screw.

NEEDLE

GUARD

SCREW

B

SCREW

SCREW

C

Fig.

25. Setting

the

Needle

Guard

i

i

•—

Fig. 26. Setting the Loopers for Timing

^

Pi

9/64"

1

!-•

9/64'

Ml

Fig. 27. Looper Point

9/64

inch

from

Needle

Loading...

Loading...