. }J

CLAMP

W

SCREWS

M

\

\<^/^

:

\Yl^

SET

SCREWS

AVOIDING

ECCENTRIC

CRANK

ECCENTRIC

EDGE

Fig.

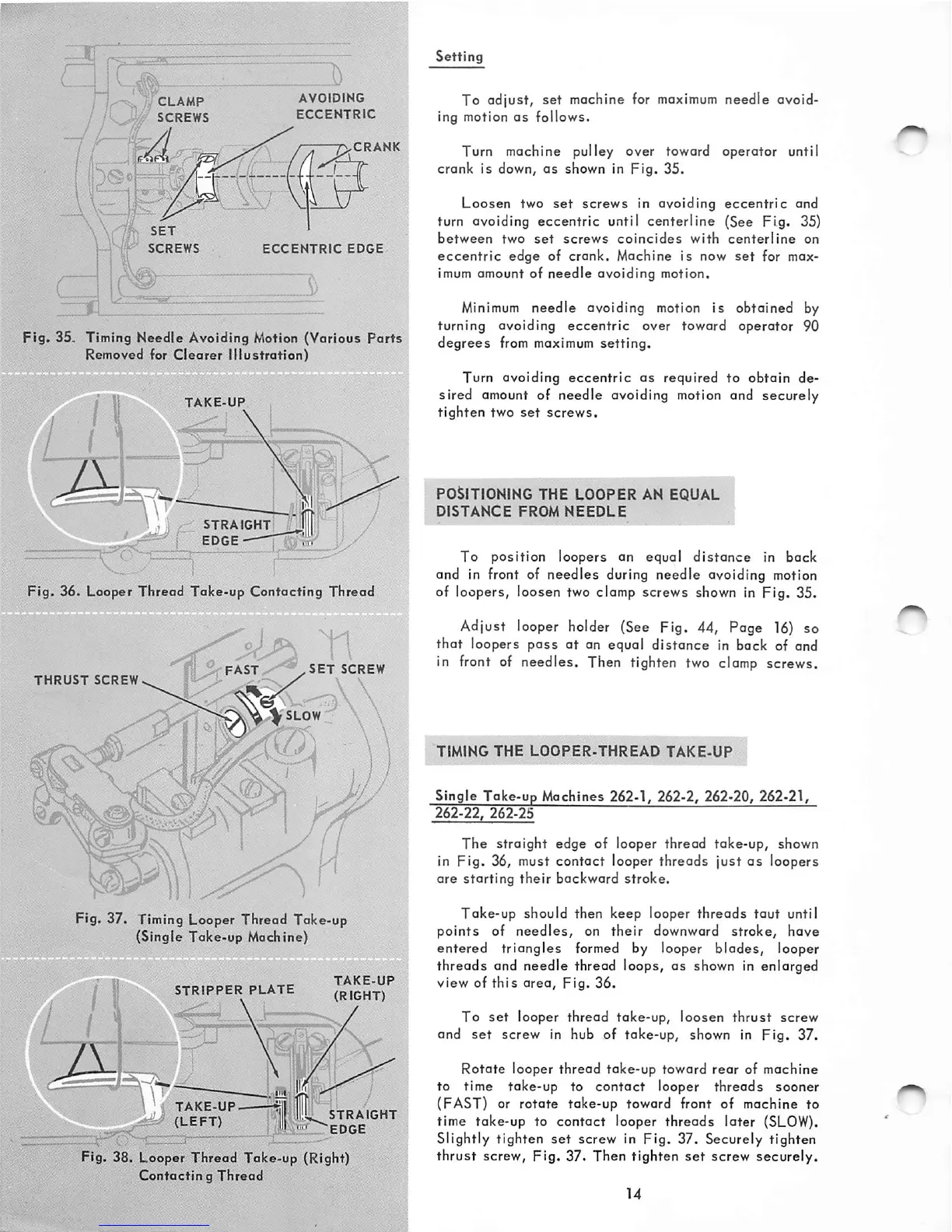

35. Timing Needle Avoiding Motion (Various

Ports

Removed

for

Clearer

Illustration)

TAKE-UP

'4

om.

iv:vxA\avrfvan

/ t

STRAIGHT

iiu.

• i /

Fig.

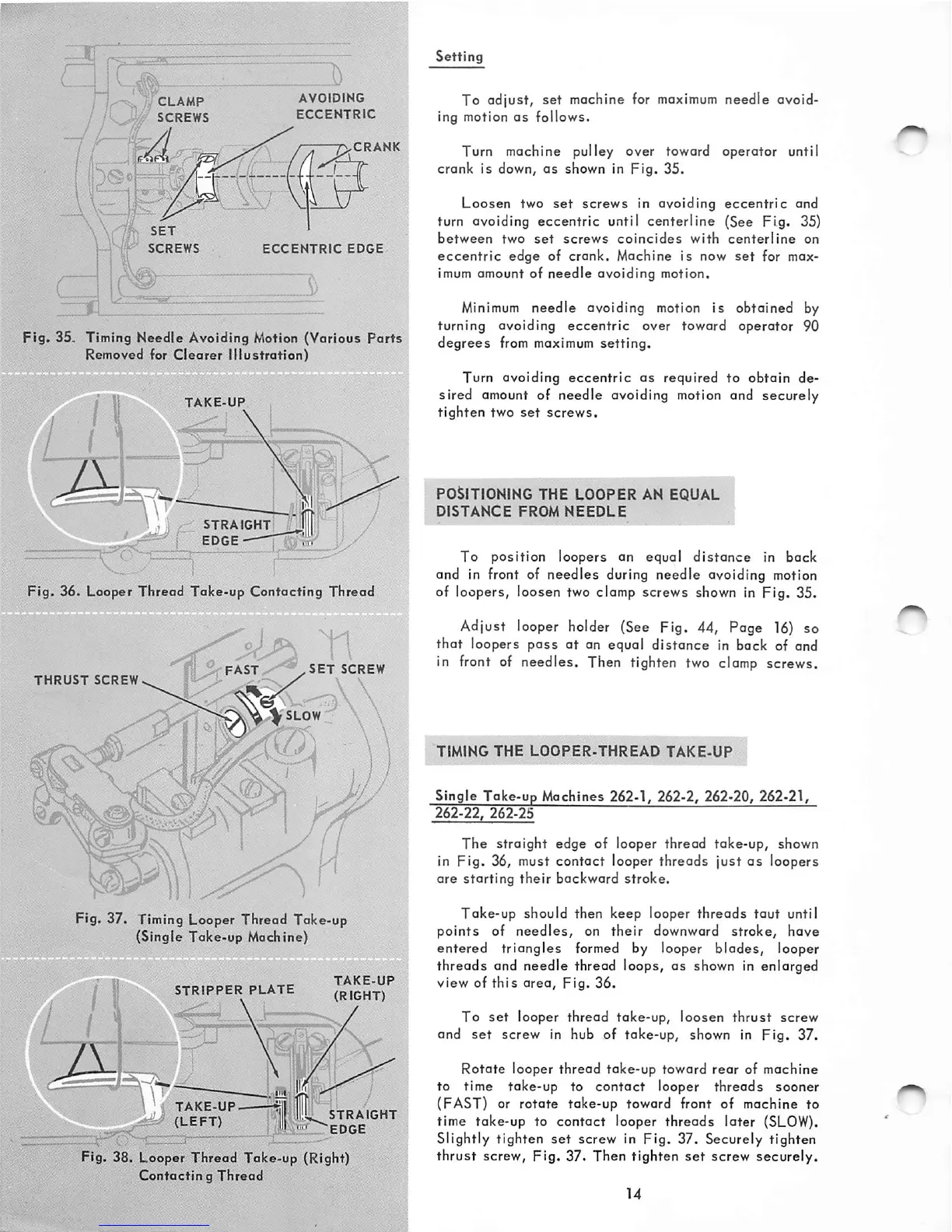

36. Looper Thread Take-up Contacting Thread

ft S-FAST-^-^^.SET

SCREW

THRUST

SCREW

V.

/

^ I l • \

Fig. 37. Timing Looper Thread Take-up

(Single Toke-up Machine)

STRIPPER

PLATE

JfiGHVT

\ ^i

TAKE-UP.

(LEFT)

STRAIGHT

'EDGE

Fig. 38. Looper Thread Take-up (Right)

Contactin

g

Thread

Setting

To adjust, set machine for

maximum

needle avoid

ing motion

as

follows.

Turn machine pulley over toward operator until

crank

is down,

as

shown in

pig.

35.

Loosen two

set

screws

in avoiding

eccentric

and

turn avoiding

eccentric

until

centerline

(See

Fig.

35)

between

two

set

screws

coincides

with

centerline

on

eccentric

edge of crank. Machine is now

set

for max

imum amount of

needle

avoiding motion.

Minimum

needle avoiding motion is obtained by

turning

avoiding

eccentric

over toward

operator

90

degrees

from

maximum

setting.

Turn avoiding

eccentric

as

required to obtain de

sired amount of needle avoiding motion and securely

tighten two

set

screws.

POSITIONING THE

LOOPER

AN EQUAL

DISTANCE

FROM

NEEDLE

To position loopers an equal

distance

in back

and in front of needles during needle avoiding motion

of loopers, loosen two clamp screws shown in Fig. 35.

Adjust looper holder (See Fig. 44, Page

16)

so

that

loopers

pass

at

an equal

distance

in back of and

in front of needles. Then tighten two

clamp

screws.

TIMING

THE

LOOPER-THREAD

TAKE-UP

Single

Take-up

Machines 262-1, 262-2, 262-20, 262-21,

262-22,

262-25

The

straight edge of looper thread take-up, shown

in Fig. 36, must contact looper threads just

as

loopers

are starting

their

backward stroke.

Take-up should then keep looper

threads

taut

until

points

of

needles,

on

their

downward stroke, have

entered triangles formed by looper blades, looper

threads and needle thread loops, as shown in enlarged

view of thi s

area.

Fig.

36.

To

set

looper thread take-up, loosen

thrust

screw

and

set

screw in hub of take-up, shown in Fig. 37.

Rotate looper thread take-up toward rear of machine

to time take-up to

contact

looper

threads

sooner

(FAST) or rotate take-up toward front of machine to

time take-up to

contact

looper

threads

later

(SLOW).

Slightly tighten

set

screw in Fig. 37. Securely tighten

thrust screw. Fig. 37. Then tighten

set

screw securely.

Loading...

Loading...