MORE

^ I;

PRESSURE^vil

LESS

PRESSURE

LOCK

NUT

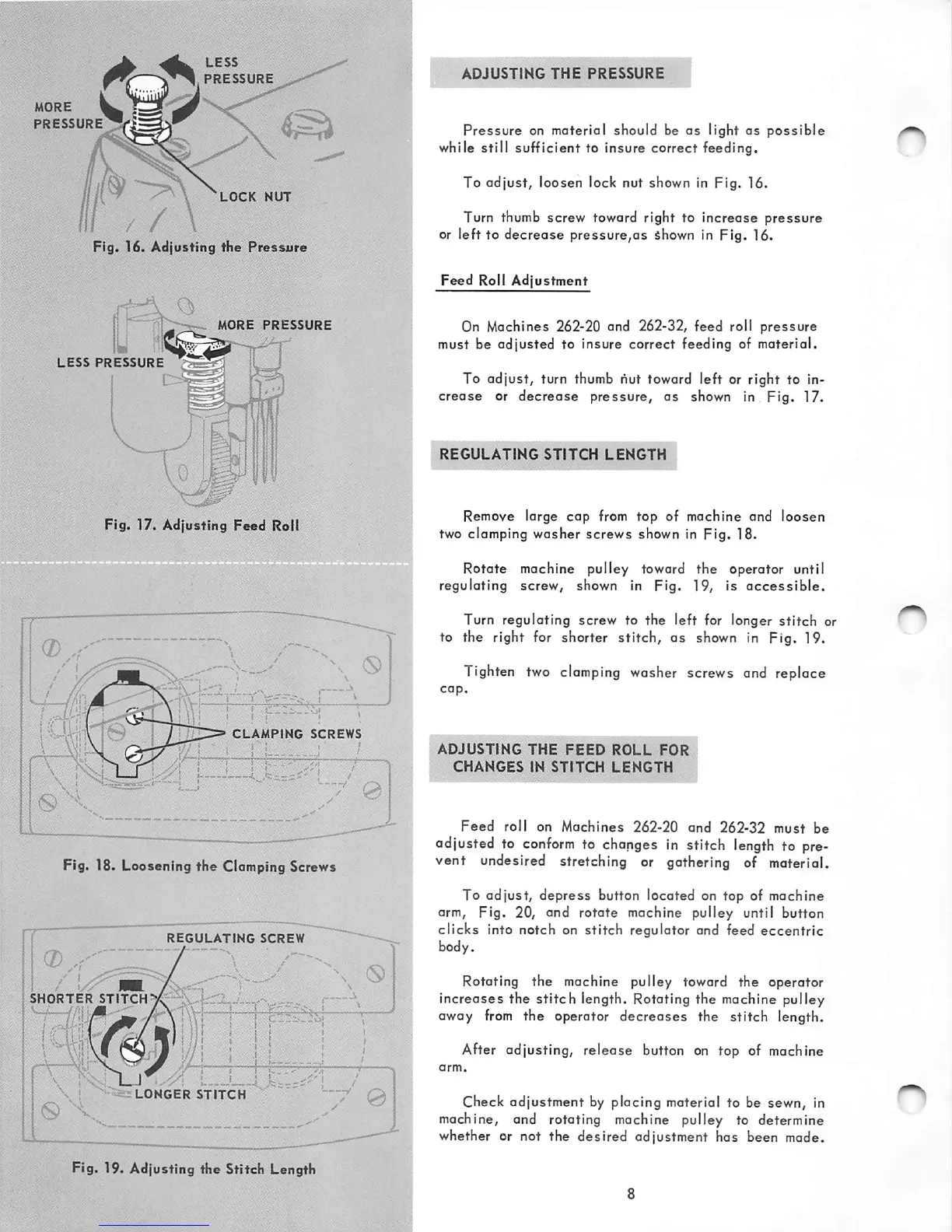

Fig. 16. Adjusting

the

Pressure

MORE

PRESSURE

LESS

PRESSURE

Fig. 17. Adjusting

Feed

Roll

/ » ^

CLAMPING

SCREWS

//

> '

Fig. 18. Loosening the Clamping Screws

REGULATiNG

SCREW

SHORTER

STITCH

(L:¥,

\\

^\{li

jiii

1

!

);

i »

..

1—I

. i J 1

LONGER

STITCH

Fig. 19. Adjusting the Stitch Length

•s

(5

ADJUSTING

THE

PRESSURE

Pressure

on material should be

as

light

as

possible

while still sufficient to insure correct feeding.

To

adjust,

loosen lock nut shown in Fig. 16.

Turn thumb screw toward right to increase

pressure

Or

left to decrease pressure,as shown in Fig. 16.

Feed

Roll Adjustment

On Machines 262-20 and 262-32, feed roll

pressure

must be

adjusted

to insure correct feeding of material.

To adjust, turn thumb hut toward left or right to in

crease

or

decrease

pressure, as shown in Fig. 17.

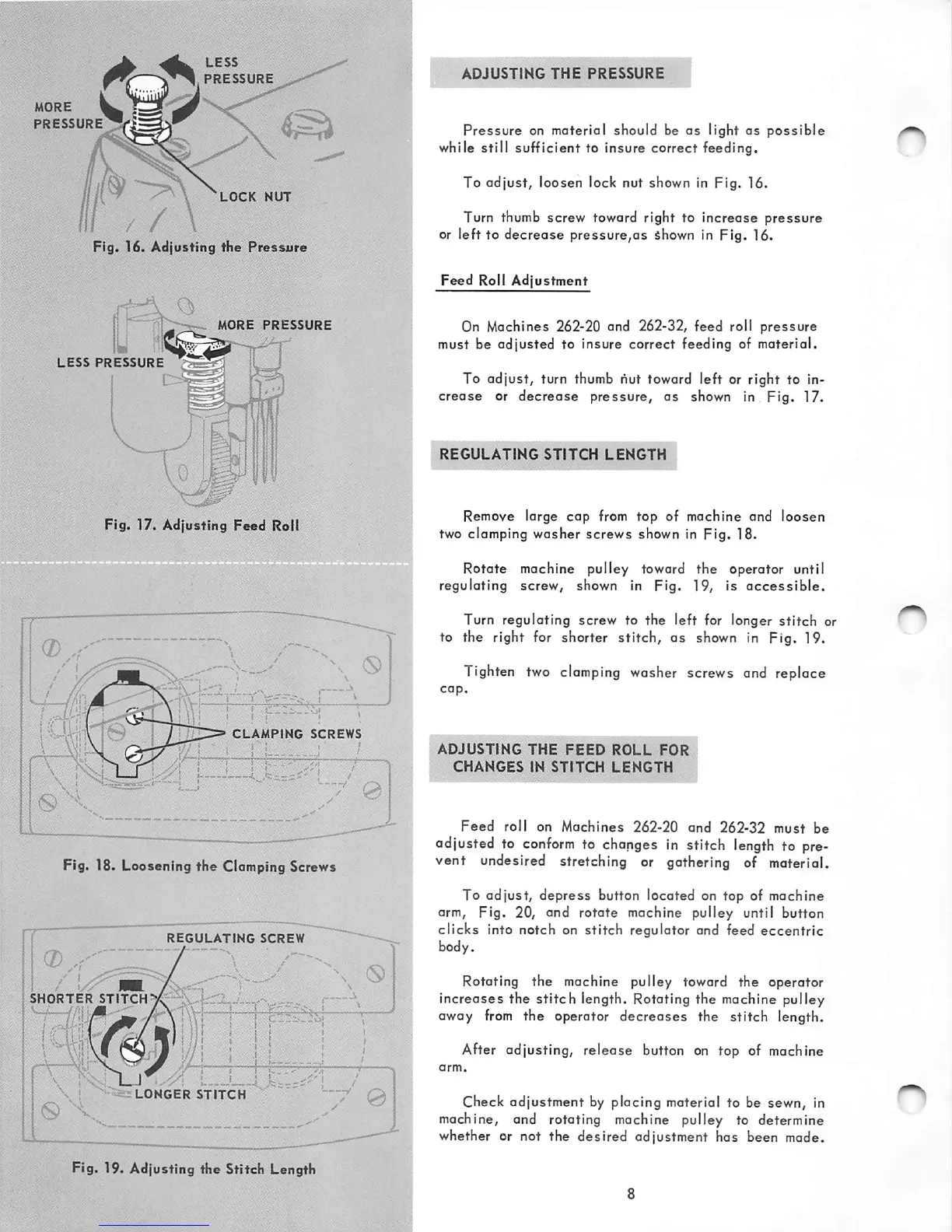

REGULATING

STITCH

LENGTH

Remove large

cap

from

top

of machine and

loosen

two clamping

washer

screws

shown in Fig. 18.

Rotate machine pulley toward the operator until

regulating screw, shown in Fig. 19, is

accessible.

Turn regulating screw to the left for longer

stitch

or

to the right for shorter stitch, as shown in Fig. 19.

Tighten two clamping washer screws and replace

ADJUSTING

THE

FEED

ROLL

FOR

^g^ANGES

IN

STITCH

LENGTH

Feed

roll on

Machines

262-20 and 262-32

must

be

adjusted to

conform

to changes in stitch

length

to pre

vent undesired stretching or gathering of material.

To

adjust,

depress

button located on top of machine

arm. Fig. 20, and rotate machine pulley until button

clicks into notch on stitch regulator and feed eccentric

body.

Rotating the machine pulley toward the operator

Increases the stitch length. Rotating the machine pulley

away

from

the operator decreoses the stitch length.

After adjusting, release button on top of machine

Check adjustment by placing material to be sewn, in

machine, and rotating machine pulley to determine

whether or not the

desired

adjustment has been made.

Loading...

Loading...