LUBRICATION

AND

CLEANING

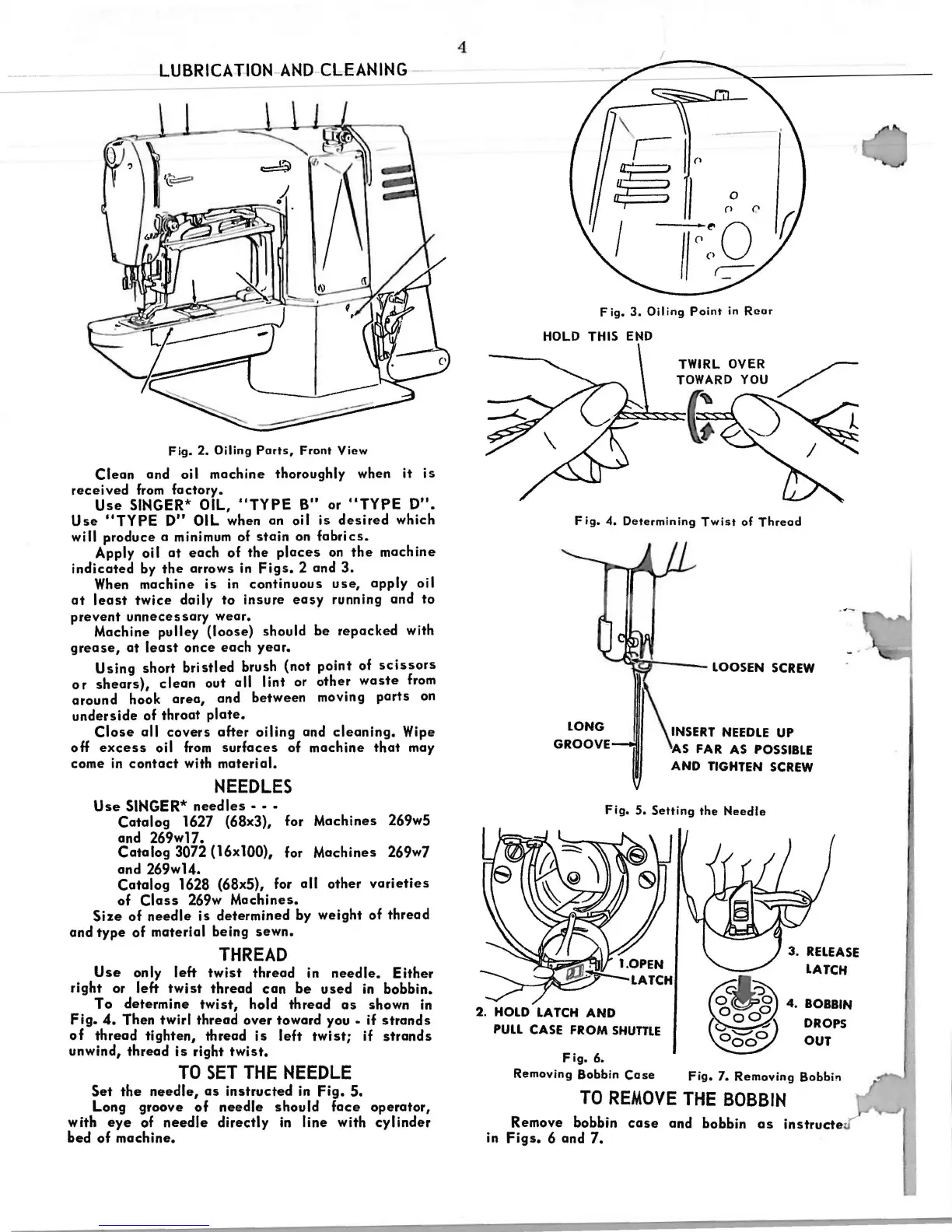

Fig.

2.

Oiling

Ports,

Front

View

Clean

and oil machine thoroughly when

it

is

received

from

factory.

Use

SIHGER* OIL,

"TYPE

B"

or

"TYPE

D".

Use

"TYPE

D"

OIL when an oil

is

desired

which

will produce a minimum of

stain

on

fabrics.

Apply oil

at

each of

the

places

on

the

machine

indicated

by

the

arrows

in

Figs.

2 and

3.

When

machine

is

in

continuous

use,

apply oil

at

least

twice

daily

to

insure

easy

running and

to

prevent

unnecessary

wear.

Machine pulley (loose) should be repacked with

grease,

at

least

once

each

year.

Using

short

bristled

brush (not

point

of

scissors

or

shears)

clean

out

all

lint

or other

waste

from

around

ho~k

area,

and between moving

parts

on

underside

of throat

plate.

Close

all

covers

after

oiling and

cleaning.

Wipe

off

excess

oil

from

surfaces

of machine

that

may

come

in

contact

with material.

NEEDLES

Use

SIHGER*

needles··

•

Catalog

1627 (68x3), for Machines 269w5

and 269w17.

Catalog

3072 (16x100), for Machines 269w7

and 269w14.

Catalog

1628 (68x5), for

all

other

varieties

of

Class

269w Machines.

Size

of

needle

is

determined by weight of

thread

and

type

of material being sewn.

THREAD

Use

only left

twist

thread

in

needle.

Either

right or

left

twist

thread

can

be

used

in

bobbin.

To

determine

twist,

hold

thread

as

shown

in

Fig.

4. Then twirl

thread

over toward you -

if

strands

of

thread

tighten, thread

is

left

twist;

if

strands

unwind,

thread

is

right

twist.

TO

SET

THE

NEEDLE

Set

the

needle,

as

instructed

in

Fig.

5.

Long groove

of

needle

should

face

operator,

with

eye

of

needle

directly

in

line with

cylinder

bed

of

machine.

4

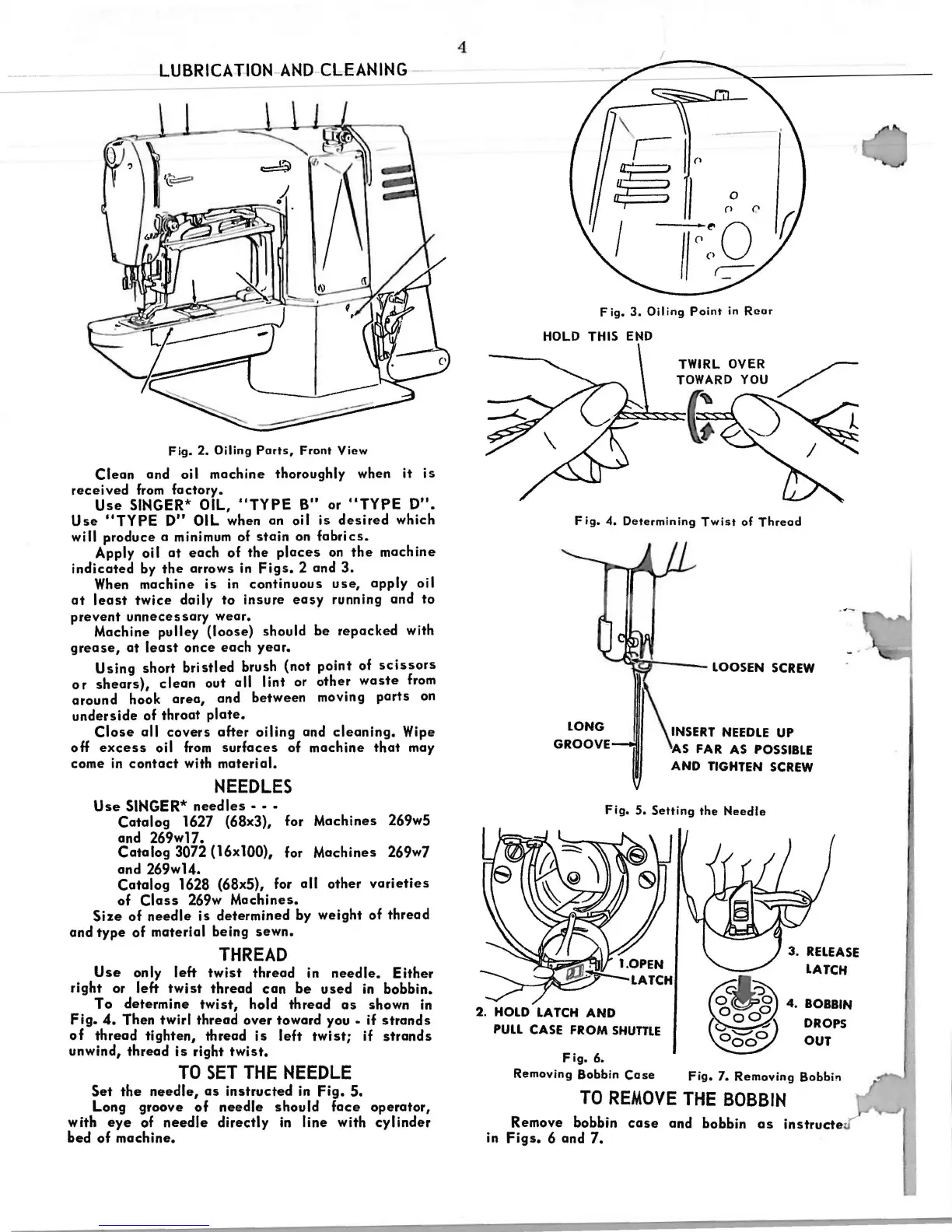

Fig.

3.

Oiling

Point

in

Rcor

HOLD THIS

END

Fig.

4.

Determining

Twist

of

Thread

~S

F~R

AS POSSIBLE

AND TIGHTEN SCREW

Fig,

5.

Setting

the

Needle

PULL

CASE FROM SHUnLE

Fig.

6.

Removing Bobbin

Cose

3.

RELEASE

LATCH

4.

BOBBIN

DROPS

our

Fig,

7.

Removing

Bobbin

TO

REMOVE

THE

BOBBIN

Remove bobbin

case

and bobbin

as

instructe

d"'

in

Figs.

6 and

7.

From the library of: Superior Sewing Machine & Supply LLC

Loading...

Loading...