11

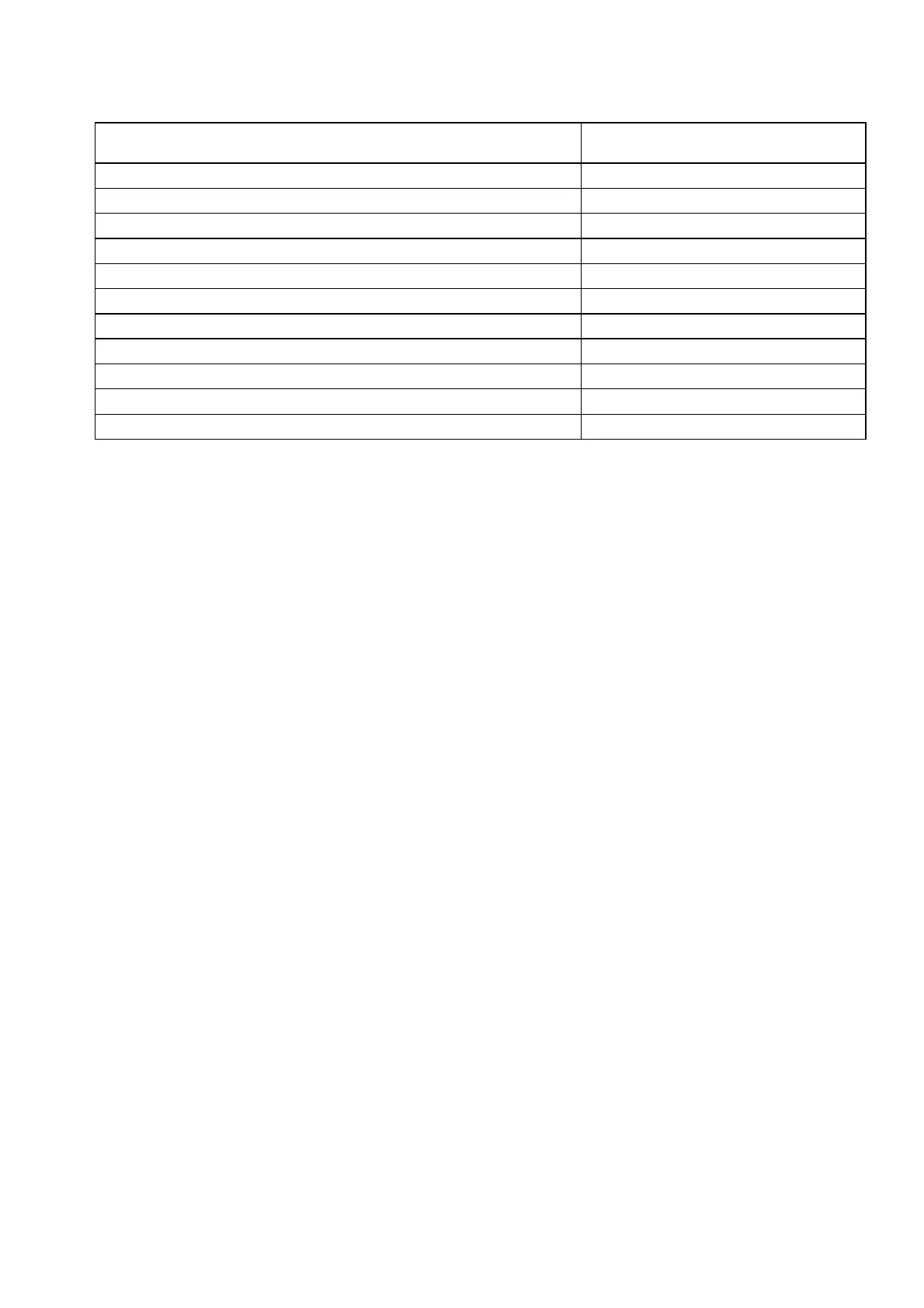

Fault Analysis

FAULT SYMTOMS

Possible Cause

Pumping Oil 1, 6, 8, 10, 18, 19

Knocks and Rattles 14, 15, 16, 17

Reduced air delivery 1, 4, 15, 18, 19

Motor tripping out or drawing excess current 7, 12, 13, 15, 17, 19, 23

Rusting Cylinders 10,11

Excessive stopping and starting 2,4,5

Compressor running very hot 3,5,9,15

Compressor not coming up to speed 12,21,27

Lights flicker when compressor runs 12,13

Abnormal piston, ring or cylinder wear 6,9,10, 20

Motor will not run 12,13,21,22,23,24

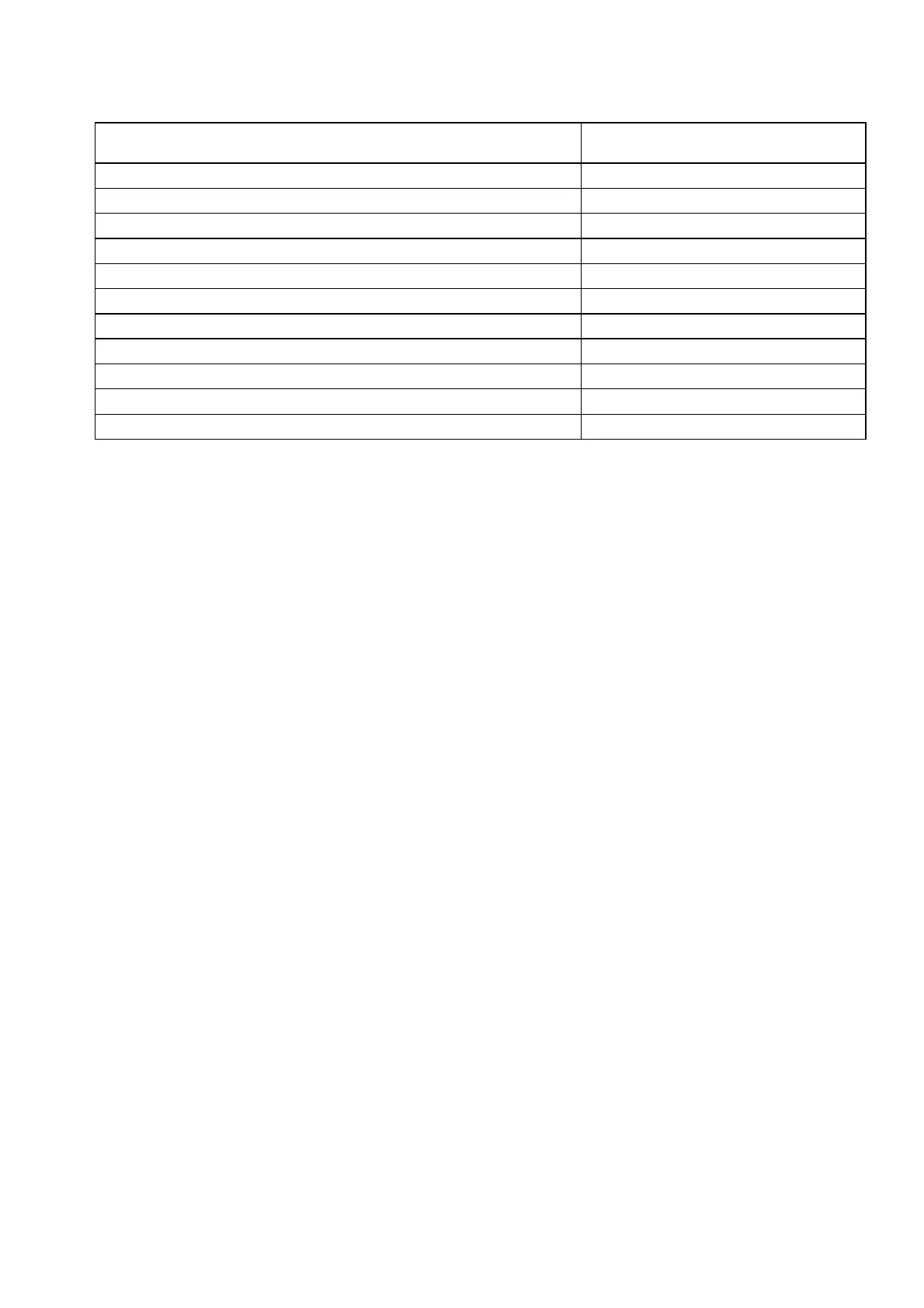

FAULT CHART

1. Clogged air intake filter.

2. Receiver needs draining.

3. Fan blocked or obstructed.

4. Air leaks in pipe work on or off compressor.

5. Receiver safety valve leaking.

6. Oil viscosity too low.

7. Oil Viscosity too high.

8. Oil Level too high.

9. Oil level too low.

10. Incorrect oil being used. Try SIP Compressor oil.

11. Extremely light duty use, or located in damp environment.

12. Check for good connections and voltages at motor terminals and starter box.

13. Poor power regulation.

14. Carbon on top of piston.

15. Leaking, broken, carbonised or loose valves or restricted airways.

16. Worn or scored connecting rod bearings.

17. Loose motor fan, defective bearings on crankshaft.

18. Broken piston rings.

19. Cylinders scratched or worn.

20. Dusty atmosphere, dirty inlet filter.

21. Faulty motor capacitors

22. Faulty pressure switch.

23. Faulty non-return valve.

24. Overload tripped.

Loading...

Loading...