-9-

9.;*=2707<=;>,=287<

%!" #!

#!!"&#

Your tool is equipped with a variable speed

trigger switch. The tool speed can be

controlled from the minimum to the maximum

nameplate RPM by the pressure you apply to

the trigger. Apply more pressure to increase

the speed and release pressure to decrease

speed. This accurate speed control enables

you to drill without center punching. It also

permits you to use as a power screwdriver.

Bits are available for driving screws as well as

running bolts and nuts.

!&!!%!"%!

#!!

After tool use, lock trigger in

“OFF” position to help prevent

accidental starts and accidental discharge.

Your tool is equipped with a forward/

reversing lever and trigger lock located above

the trigger (Fig. 1). This lever was designed for

changing rotation of the bit, and for locking the

trigger in an “OFF” position.

For forward rotation, (with chuck pointed away

from you) move the lever to the far left.

For reverse rotation move the lever to the far

right. To activate trigger lock move lever to the

center off position.

8 78= ,1*70.-2;.,=287 8/

;8=*=287>7=25=1.=885,86.<

=8*,8695.=.<=89Shifting during rotation of

the chuck can cause damage to the tool.

!

When the trigger switch is released it activates

the brake to stop the chuck quickly. This is

especially useful in the repetitive driving and

removal of screws.

!"#

Your tool is equipped with two separate gear

ranges, Hi-torque and High-speed. Hi-torque

provides high-torque and slower drilling speeds

for heavy duty work or for driving screws. High-

speed provides faster speeds for drilling lighter

work. To change speeds slide switch, to the

Hi-torque or High-speed position (Fig. 1).

"##™

Your tool is also equipped with a light that

turns on automatically when the switch is

activated for better visibility during operation

(Fig. 1). The Site-Light™ is maintenance free

and was designed to last the life of your tool.

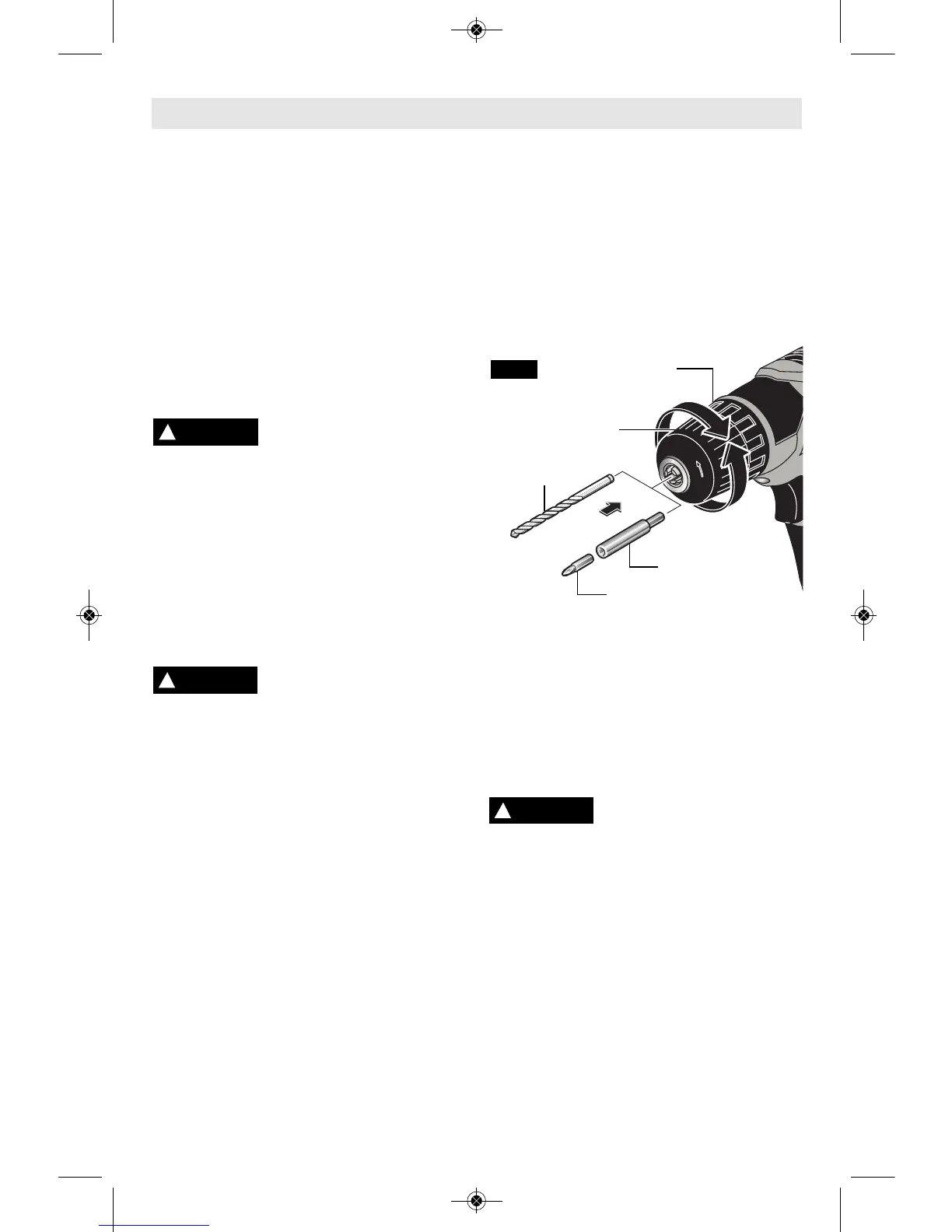

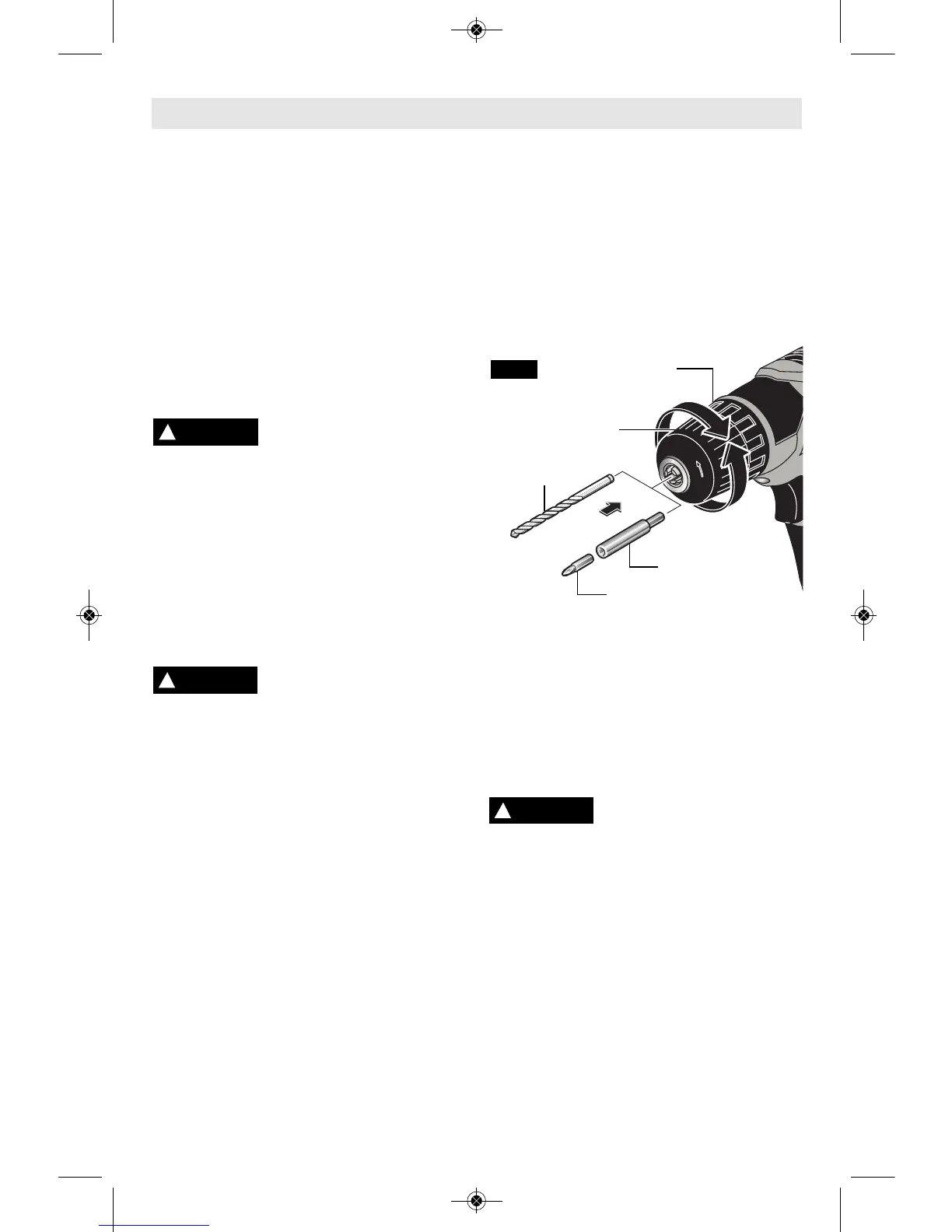

"!##

Move reverse switch lever to the center “OFF”

position. Disconnect battery pack from tool.

Viewing from chuck end, hold the chuck collar

firmly with one hand and rotate the chuck

sleeve counter-clockwise with the other hand

and open chuck to approximate bit diameter

(Fig. 2).

For small bits, open jaws enough to insert the

bit up to the flutes. For large bits, insert the bit

as far as it will go. Center the bit as you close

the jaws by hand. This positions the bit

properly, giving maximum contact between the

chuck jaws and the bit shank.

To tighten, hold the chuck collar firmly with one

hand and se curely tighten the chuck sleeve

clockwise with the other hand (Fig. 2).

8 78= ><. =1. 98@.; 8/

=1. -;255 @125. 0;*<9270

,1>,4=8588<.78;=201=.7+2= Friction burn

or hand injury is possible if attempting to

grasp the spinning chuck.

"!#!"

##!(

Release battery pack from tool by pressing

on both sides of the battery release tabs and

pull downward (Fig. 1).

To insert battery, align battery and slide

battery pack into tool until it locks into position.

Do not force.

!

WARNING

!

CAUTION

!

WARNING

BIT HOLDER

SCREWDRIVER BIT

DRILLBIT

CHUCK SLEEVE

Clockwise

Counter

clockwise

CHUCK COLLAR

FIG. 2

SM 1619X06384 06-11:SM 1619X06384 06-11.qxp 6/30/11 10:00 AM Page 9

Loading...

Loading...