Section 2 - List of Tables

SJIII Series

General Maintenance

Before attempting any repair work, disconnect the battery by turning the emergency main power

disconnect switch to off position. Preventive maintenance is the easiest and least expensive type of

maintenance.

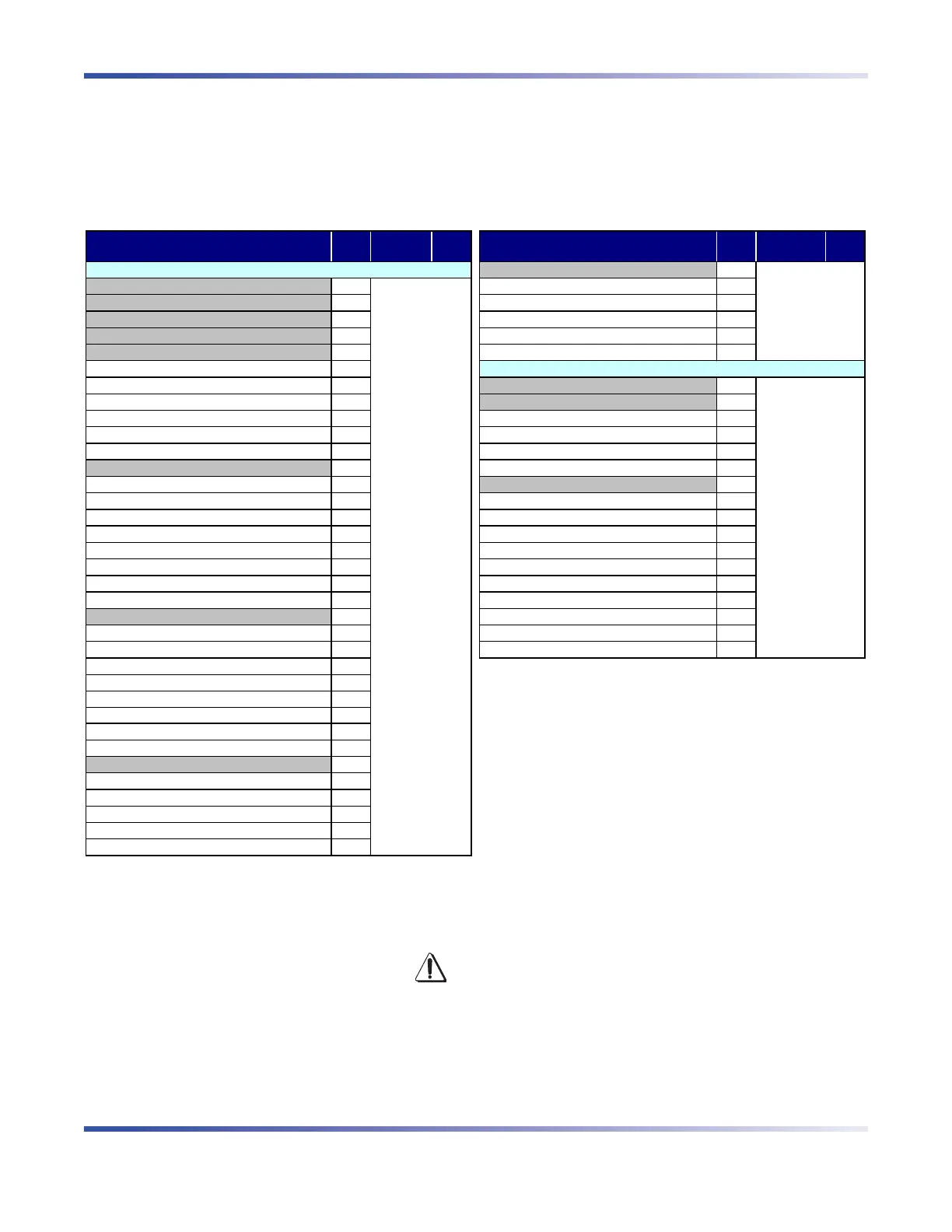

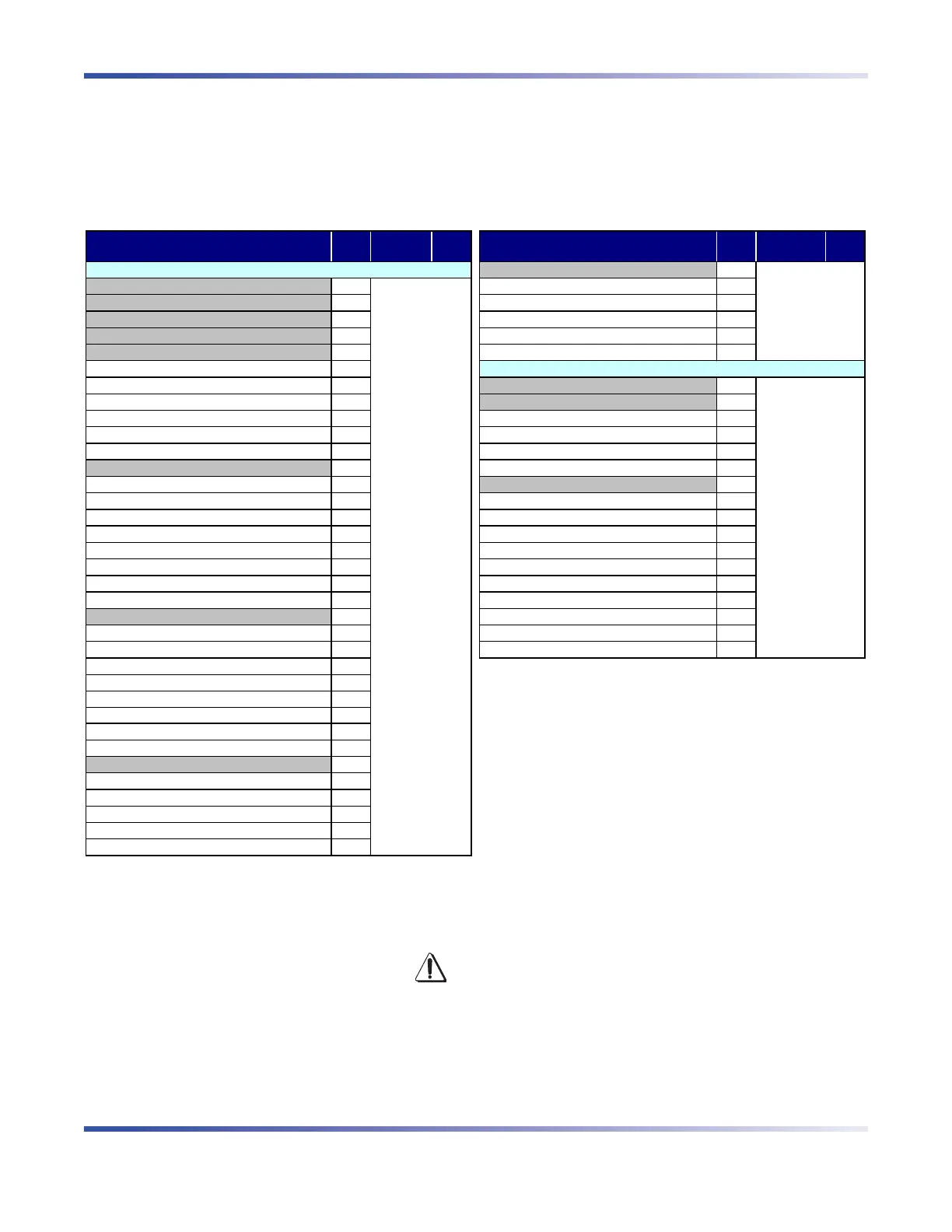

Table 2.5a Maintenance and Inspection Schedule - ANSI/CSA

Frequency

Daily

3 months or

150 hours

Yearly

Frequency

Daily

3 months or

150 hours

Yearly

Lifting Mechanism

Labels A Maintenance Support A

Electrical A Scissor Assembly A

Limit Switches A Scissor Bumpers A

Hydraulic A Rollers A

Entrance Side Lift Cylinder(s) A

Emergency Main Power Disconnect Switch A

Base Control Switches A Test Emergency Main Power Disconnect Switch A

Free-wheeling Value Knob A Base Control Console

Brakes A Test Enable Button (If Equipped) A

110V Outlet Receptacle A Test Platform Raise/Lower Switch A

Ladder A Test Emergency Lowering A

Battery Tray Side Test Free-wheeling A

Pothole Protection Device A Platform Control Console

Battery Tray A Test Platform Emergency Stop A

Battery Charger A Test Enable Trigger Switch A

Battery A Test Steering A

Steer Cylinder Assembly A Test Driving A

Wheel/Tire Assembly A Test Brakes A

Tie Rod (Conventionals) A Test Platform Raising/Lowering A

Greasing Points A Test Horn A

Hydraulic/Electric Tray Side Test Pothole Sensor A

Pothole Protection Device A Test Speed Limit A

Hydraulic Tank A Test Tilt Sensor A

Hydraulic Oil A

60598AA-ANSI

Hydraulic Pump and Motor A

Electrical Panel A

Proportional and Main Manifolds A

Tilt Sensor A

Emergency Lowering Access Rod (If Equipped) A

Platform Assembly A

Lanyard Attachment Anchors A

AC Outlet on Platform A

Platform Control Console A

Manuals A

Powered Extension Control Console (If Equipped) A

A - Perform Visual and Daily Maintenance Inspections & Functions Test. Refer to Section 2.8 and Section 2.9 of the operating manual.

B - Perform Scheduled Maintenance Inspection. Refer to Service & Maintenance manual.

* - Maintenance must be performed only by trained and competent personnel who are familiar with mechanical procedures.

Visual and Daily Maintenance Inspections

Function Tests

B*

B*

B*

WARNING

Loading...

Loading...