Donot operate when

tank is empty

Donot use flammable

solution

Caution pollution when

disposal this product.

Please use the ground

wire correctly

WARNINGS

Regularly use high-pressure wind blown away dust for electrical parts Clean the tank at least

once a week

Maintenance

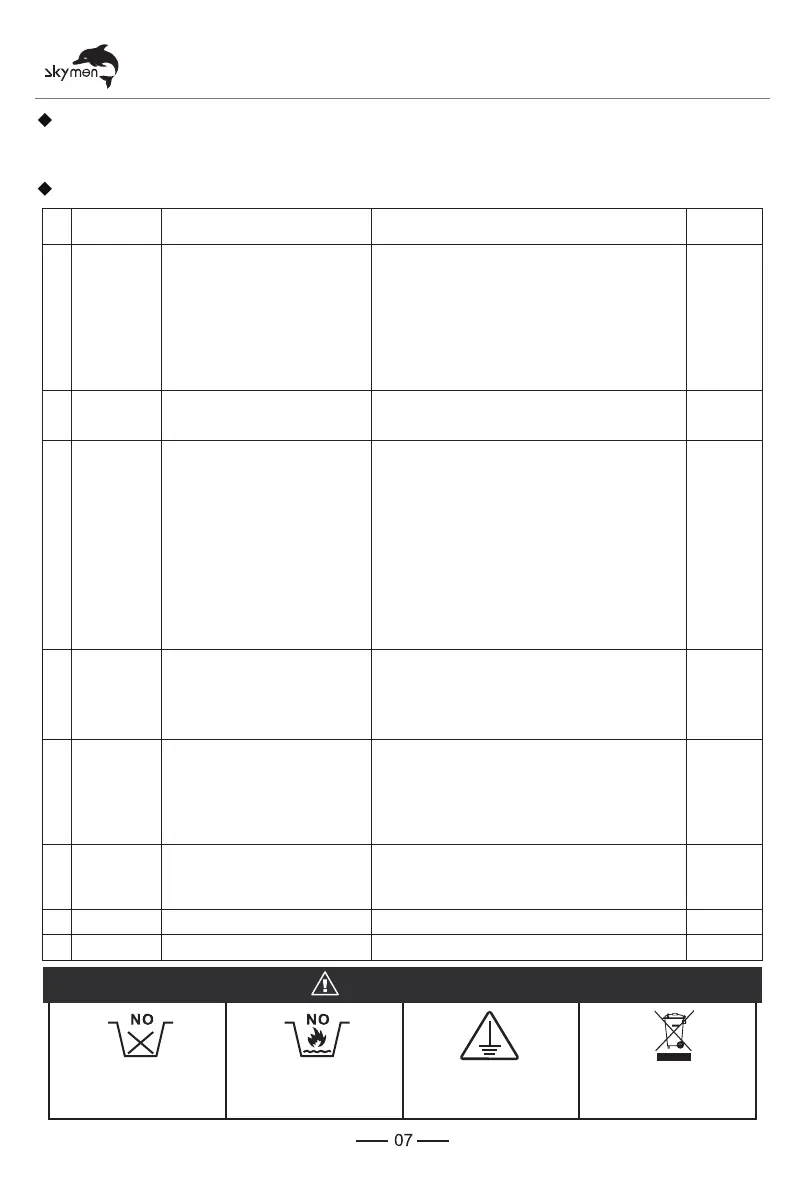

Troubleshooting

No Problems

No

Ultrasonic

Time control

failure

A.Timer failure

B.other reasons

Electricleakage

Scrap

A.The equipment ground wire is not

connected well.

A.Check whether the internal ground wire and power cable

grounding of the device are connected.

B.Check if the internal live wire or neutral wire of the

machine is fall off.

According to the state related laws and designated

units for discarded medical equipment

B.The internal live line or neutral line

of the equipment falls off

A.Replace timer or digital control panel

B.Inquiry our after service engineer

Not well

cleaning

A.too high too low liquid surface

B.too high too low temperature

C.Not suitable cleaning liquid

D.Other reasons

A.Adjust liquid into the best surface

B.Adjust temperature into the most fitted

C.Stop and switch off power supply,replace

suitable liquid after the previous liquid cool down

D.Inquiry our after service

engineer

Temperature

control

failure

A.Thermostant loosen

B.Thermostat tube broken

C.Digital display out of control

D.Other reasons

A.Fasten the thermostat header.

B.Replace thermostat.

C.Check the broken part and change it.

D.Inquiry our after service engineer

No heating

Suggestion

50-60°C

Suggestion

50-60°C

A.Heater power switch bad

linkage

B.Fuse burn out

C.Heating pad burn out

D.Digital display board out of

control

E.Incorrect temperature setting

A.Check heating plug and connect well.check

outlet line with multimeter:if OK and resistance

value is few hundred OHMs.

B.Change the same specification fuse

C.Replace the bad heating pad if open circuit

D.Check the broken part and change it

E.The set temperature must be 3°C higher than

the actual temperature before heating can be

turned on. Please reset the temperature.

F.Other reasons

F.Inquiry our after service engineer

A.Power supply not connect

B.Fuse broken

C.Cable short circult

D.Transducer short circult

E.PCB Board broken

F.Other reasons

A.

Check and plug power switch

B.Check the fitted power supply and change the

same specification fuse

C.Connect fitted cable or replace a new

D.Inquiry our after service engineer

E.Check the broken part and change it

F.Inquiry our after service engineer

Possible causes Solutions Remarks

1

2

3

4

5

6

7

Other problems

Consult our after service:+86-755-2978472568

www.skymen.cc

Loading...

Loading...