28

If the product is out of service.

Battery fault (emergency power): signalled locally by a yellow LED and remotely by dry contact with delay

(failsafe).

If the battery is not present:

The battery test is performed in the following manner: every 30 seconds for the first 20

minutes after commissioning: every 15 minutes after the first 20 minutes. If a fault is detected,

the test is performed every 30 seconds up to 20 minutes after the fault disappears.

If the internal impedance is too high (test every 4 hours maximum on a charged battery).

The impedance limit values are:

24 V 48 V

50-75 W

650m ±10 %

-

100-150 W

410m ±10 % 1,65 +/-10%

200-300 W

164m ±10 % 656m ±10 %

400-600 W

82m ±10 % 328m ±10 %

If the battery voltage < 1.8 V/cell±5 %.

Output 1 voltage presence : signalled locally by a green LED

Output 2 voltage presence : signalled locally by a green LED

Voltage presence on output 1 and 2 is signalled by a dry contact with delay (failsafe).

5.2 Summary of available equipment

Range

Temperature

compensation

Battery low voltage cut-

out

Battery current

limitation

ES 50 W - 75 W ***/

/

ES 150 W to 600 W

***only VDS-certified AES 50 and 75 W models are equipped with a sensor.

Temperature compensation:

A battery voltage compensation system maintains the charge characteristics within the limits specified

by the battery manufacturer across the entire operational temperature range.

Battery current limitation:

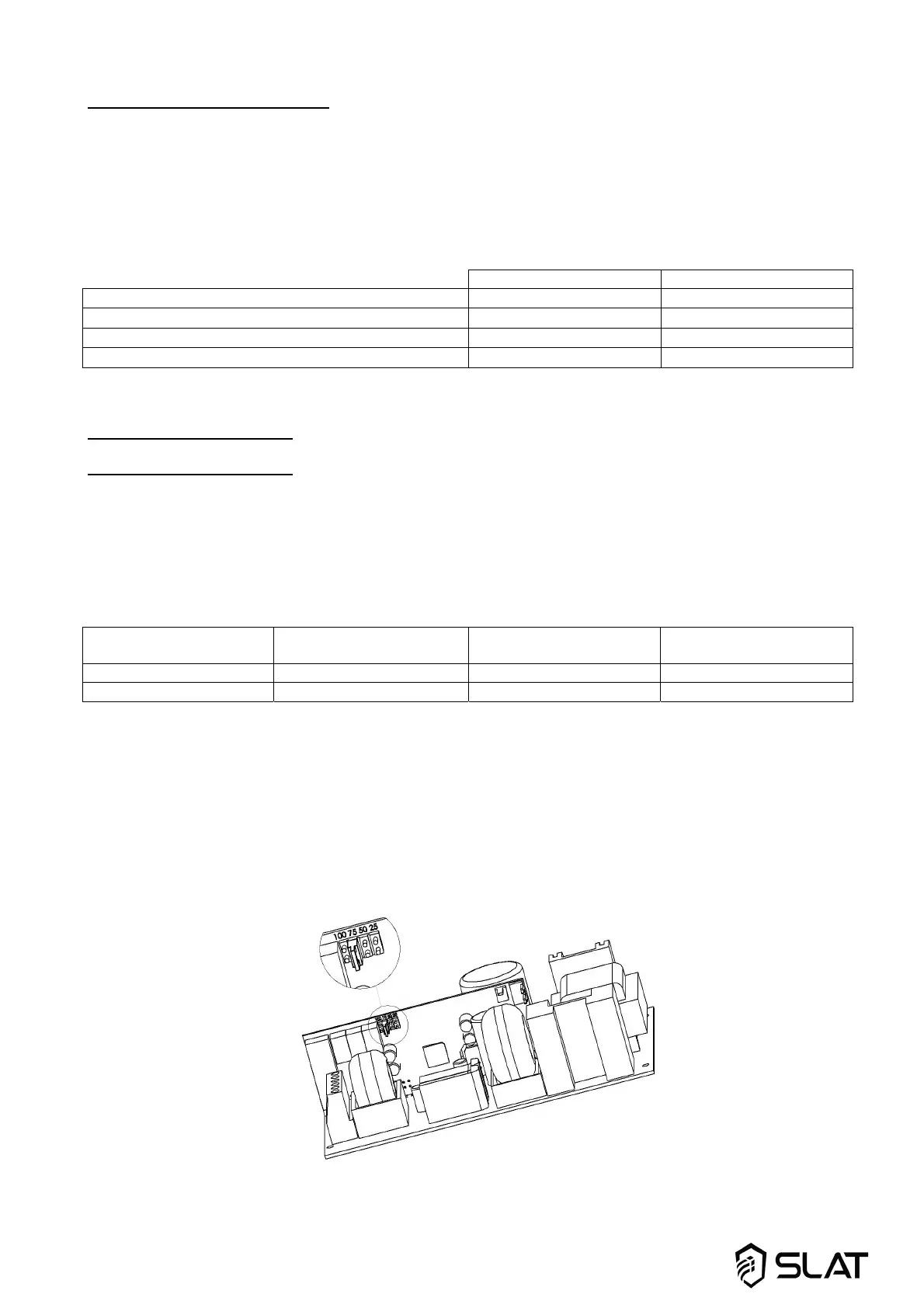

The battery charge current can be set to 25 %, 50 %, 75 % of the rated current (In) using a

configuration jumper on daughterboard positions ‘25’, ‘50’, ‘75’.

Daughterboard jumper

Loading...

Loading...