Drive one mile to dispense sealant throughout the tire, allowing it to seek out and seal the

puncture. Recheck tire pressure to verify that the puncture has been sealed.

At your earliest convenience take your vehicle to a tire repair facility for a permanent

professional repair. Inform tire repair specialist that Slime is in the tire.

FLAT TIRE REPAIR INSTRUCTIONS:

BEFORE STARTING: Inspect tire tread for puncturing object(s) and remove if possible.

NOTE: Seals punctures up to 1/4" (6mm). Correct tire pressure can be found in your vehicle’s

owner’s manual or driver side doorjamb.

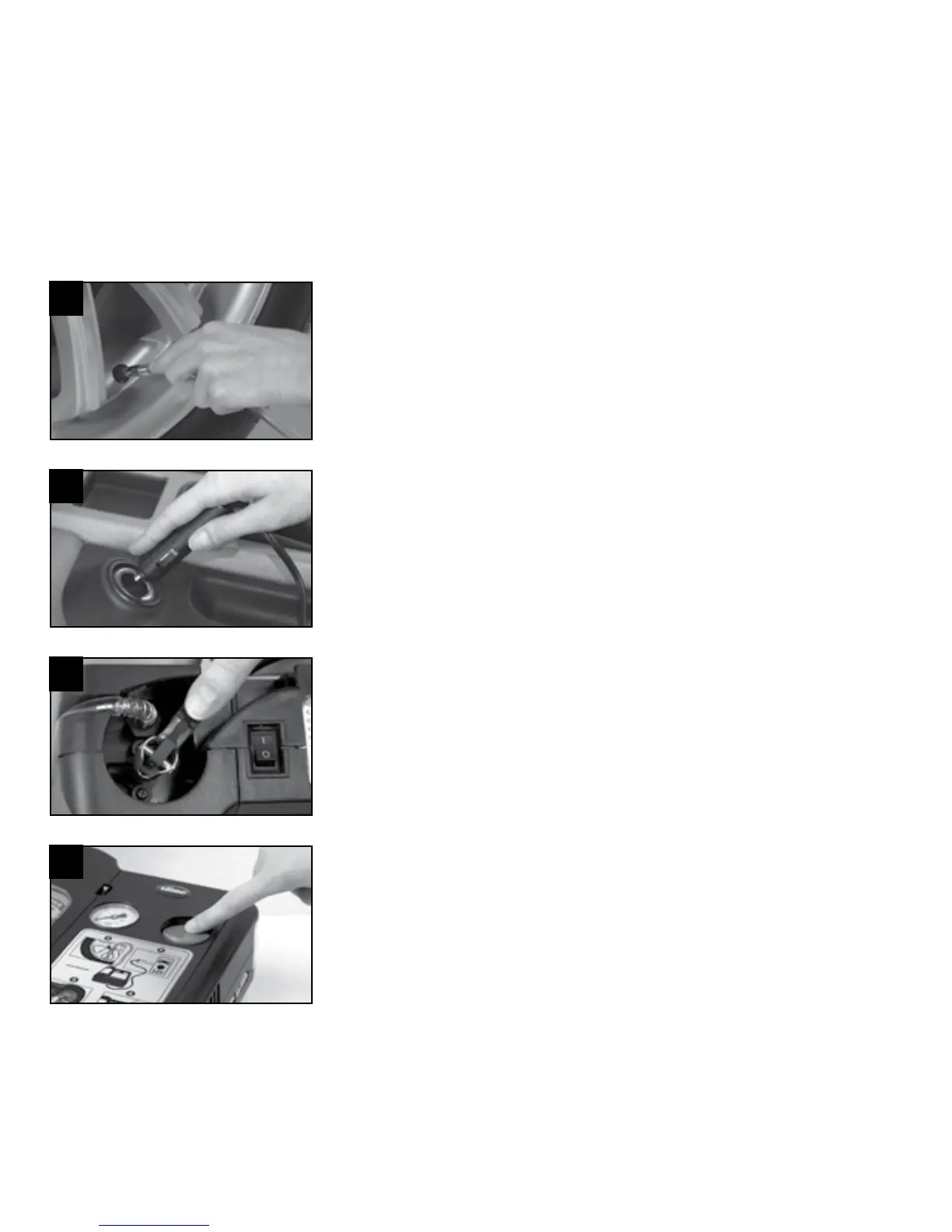

1. Attach (clear) sealant hose to tire valve stem.

NOTE: Lay Safety Spair flat on the ground facing

upward.

2. Plug inflator into accessory power outlet. Do not run

vehicle while inflator is operating.

3. Attach (black) air hose to sealant cartridge nozzle,

located at the top of the sealant cartridge.

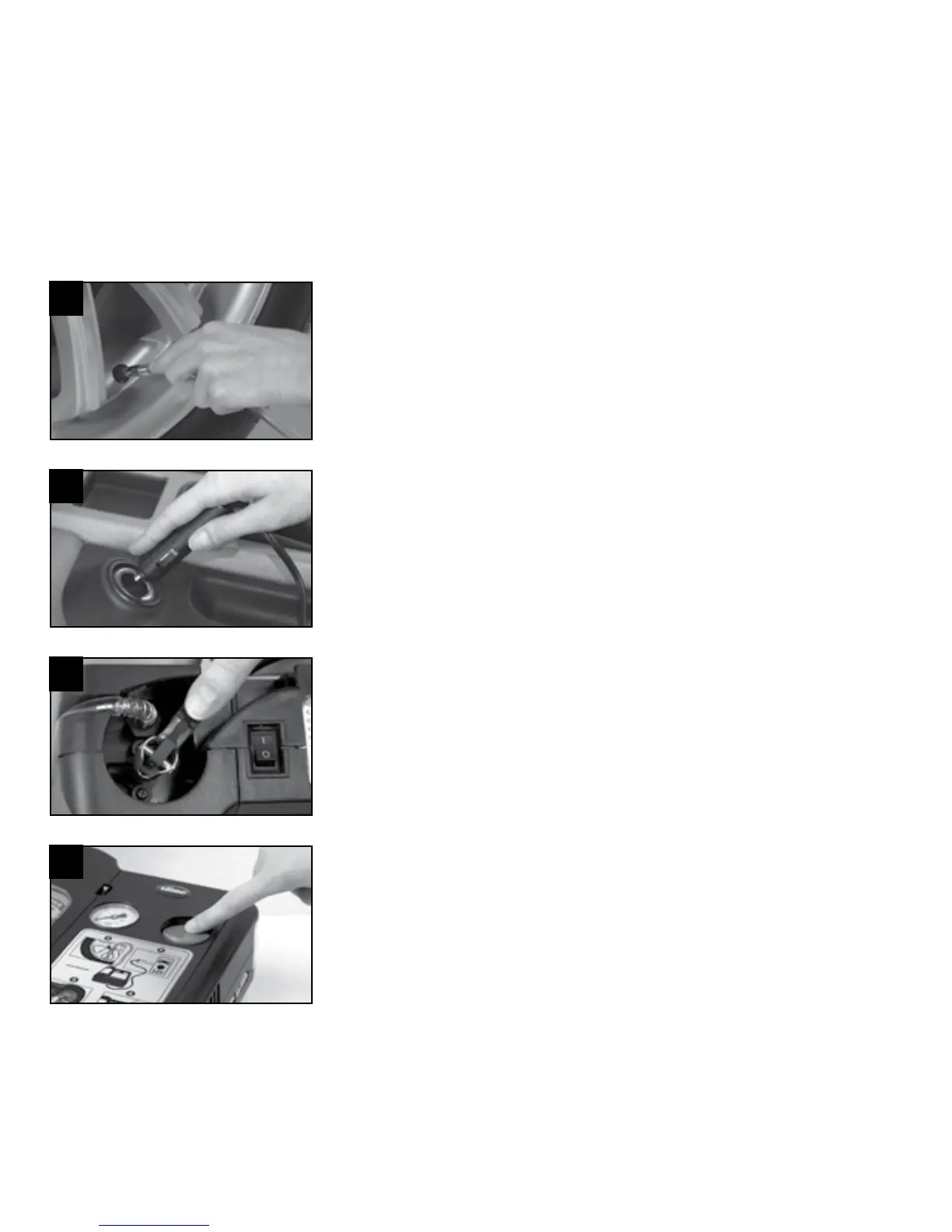

4. Push the green button to turn the system on. Wait 6

minutes (in temperatures below 32˚F wait 12 minutes).

Some sealant may remain in the hose. Turn system off

and check tire pressure. If additional air is needed follow

“air only” instructions. Once correct tire pressure has

been achieved disconnect the system.

1

2

3

4

Loading...

Loading...