4

3

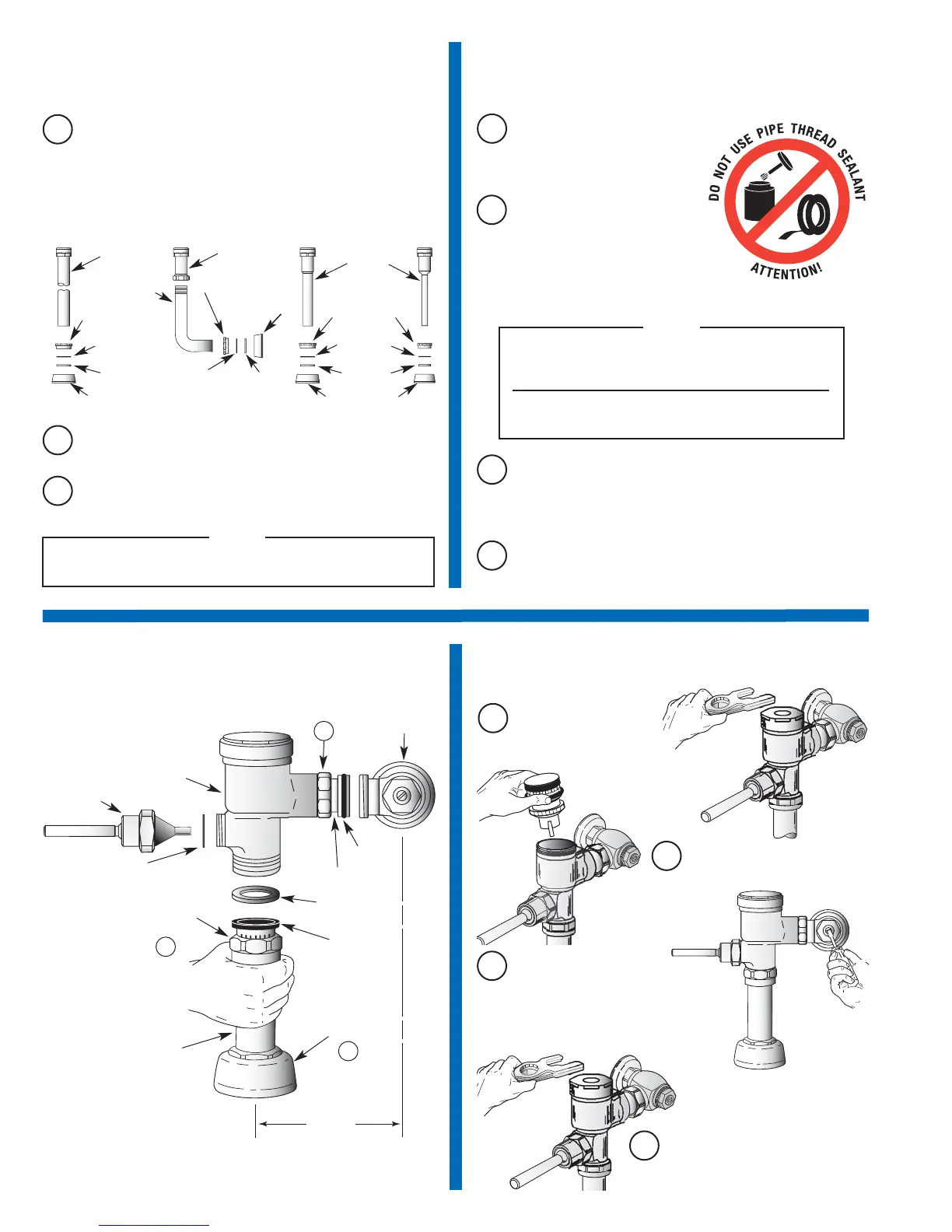

Install Vacuum Breaker Flush

Connection

VACUUM

BREAKER

TUBE

SPUD COUPLING

NYLON SLIP

GASKET

RUBBER

GASKET

SPUD FLANGE

A

Slide Spud Coupling, Nylon Slip Gasket, Rubber Gasket and Spud

Flange over Vacuum Breaker Tube.

B

Insert Tube into Fixture Spud.

C

Hand tighten Spud Coupling onto Fixture Spud.

VACUUM

BREAKER

TUBE

SPUD COUPLING

NYLON SLIP

GASKET

RUBBER

GASKET

SPUD FLANGE

SPUD COUPLING

NYLON

SLIP

GASKET

RUBBER

GASKET

SPUD FLANGE

MODELS 110/111,

115, 136

MODELS 120,

121, 122, 137

MODEL 180 MODEL 186

ELBOW FLUSH

CONNECTION

4A

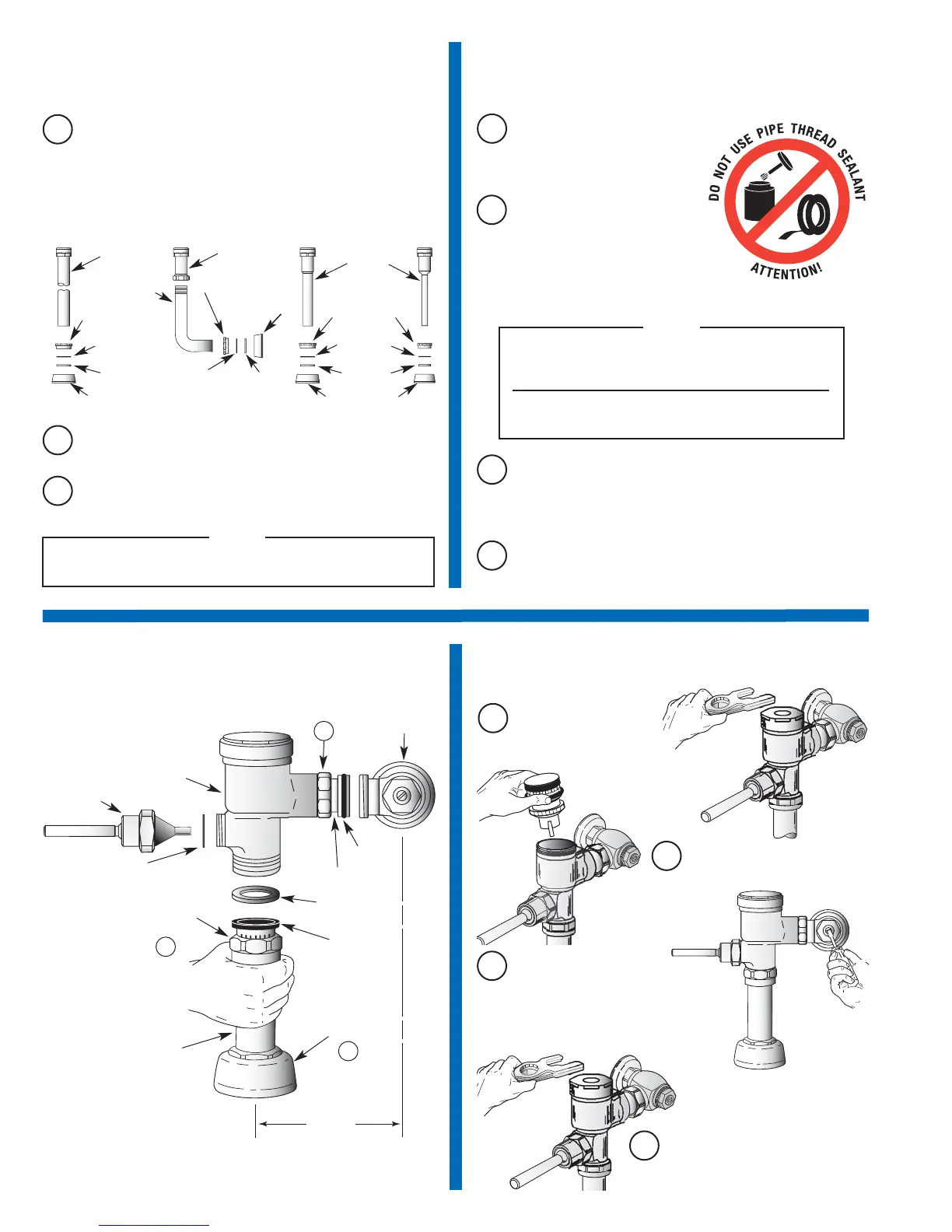

Install Flushometer

4B

Install Flushometer (Continued)

C

Align Flushometer Body and securely tighten first the Tailpiece

Coupling (1), then the Vacuum Breaker Coupling (2), and finally

the Spud Coupling (3). Use a wrench to tighten these couplings in

the order shown.

B

Align Flushometer directly above

the Vacuum Breaker Flush

Connection by sliding the

Flushometer Body IN or OUT as

needed. Tighten Vacuum Breaker

Coupling by hand.

A

Lubricate tailpiece O-ring with

water. Insert Adjustable Tailpiece

into Control Stop. Tighten

Tailpiece Coupling by hand.

Maximum adjustment of the Sloan Adjustable Tailpiece is

1/2" (13 mm) IN or OUT from the standard 4-3/4" (121 mm)

(centerline of Flushometer to centerline of Control Stop).

If roughing-in measurement exceeds 5-1/4” (133 mm),

consult factory for longer tailpiece.

NOTE

TAILPIECE COUPLING

CONTROL

STOP

1

FLUSHOMETER

BODY

VACUUM

BREAKER

COUPLING

2

ADJUSTABLE TAILPIECE

O-RING

G-44 FRICTION

RING

SPUD

COUPLING

3

C/L

FIXTURE

C/L

SUPPLY

VACUUM

BREAKER

FLUSH

CONNECTION

4-3/4”

(121 mm)

±1/2”

(13 mm)

5

Flush Out Supply Line

A

Make sure Control Stop

is CLOSED and remove

Flushometer Cover.

C

Install Flushometer Cover wrench

tight. Open Control Stop to flush

supply line. Close Control Stop

and remove Flushometer Cover.

B

Lift out Piston Assembly.

D

Reinstall Piston Assembly and

Flushometer Cover. Tighten

Flushometer Cover wrench tight.

VACUUM

BREAKER

On valves furnished less vacuum breaker (XYV Variation) connect flush

tube to the bottom of the valve using the slip gasket supplied.

NOTE

HANDLE

ASSEMBLY

GASKET

D

If not installed, install Handle Assembly with Gasket to handle

opening on Flushometer Body. Tighten Handle Assembly securely.

VACUUM

BREAKER

REPAIR

KIT

Loading...

Loading...