Repair Parts and Maintenance Guide

78

Sensor Flushometers

The information contained in this document is subject to change without notice.

IMPORTANT: The OPTIMA PLUS

®

ushometer is engineered for quiet

operation. Excessive water ow creates noise, while too little water ow

may not satisfy the needs of the xture. Proper adjustment is made when

plumbing xture is cleansed after each ush without splashing water out

from the lip AND a quiet ushing cycle is achieved.

Never open Control Stop to where the ow from the valve exceeds the ow

capability of the xture. In the event of a valve failure, the xture must be

able to accommodate a continuous ow from the valve.

ATTENTION INSTALLERS: With the exception of the control stop inlet,

DO NOT USE pipe sealant or plumbing grease on any valve component or

coupling! To protect the chrome or special nish of Sloan ushometers,

DO NOT USE toothed tools to install or service these valves. Use our A-50

Super-Wrench

™

or other smooth-jawed wrench to secure couplings.

Regulations for low consumption xtures (1.6 gpf/6.0 Lpf closets and

1.0 gpf/3.8 Lpf urinals) prohibit use of higher ush volumes.

1. Sensor fl ashes continuously only when user steps within range.

A. Unit in start-up mode; no problem. This feature is active for the

rst 10 minutes of operation.

2. Valve does not fl ush; sensor not picking up user.

A. Range too short; increase the range.

B. Optima Plus installed on a high rough-in xture (beam is shooting

over the user’s head). Install the EBV-46-A beam de ector (black

modules only).

3. Valve does not fl ush; sensor picking up opposite wall or surface,

or only fl ushes when someone walks by. Red light fl ashes

continuously for fi rst 10 minutes even with no one

in front of the sensor.

A. Range too long; shorten range.

B. Sensor is picking up mirror or highly re ective wall or surface in front

of xture. Install Optima Plus

®

slightly “off-center” (2 to 5 degrees) to

eliminate direct re ection off of mirror or opposite wall or surface.

4. Valve does not fl ush even after adjustment.

A. Range adjustment potentiometer set at full “max” or full “min”

setting. Readjust potentiometer away from full “max” or “min” setting.

B. Batteries completely used up; replace batteries.

C. Problem with electronic sensor module; replace electronic sensor

module.

5. Unit fl ashes 4 quick times when user steps within range.

A. Batteries low; replace batteries.

6. Valve does not shut off.

A. By-pass ori ce in diaphragm is clogged with dirt or debris, or by-pass

is clogged by an invisible gelatinous lm due to “over-treated” water.

Remove diaphragm and wash under running water. Replace with new

diaphragm if cleaning does not correct the problem.

B. Dirt or debris fouling stem or ex tube diaphragm. Remove ex

tube diaphragm and wash under running water.

C. Problem with solenoid. If cleaning does not correct the problem,

replace with new isolated solenoid operator.

7. Not enough water to fi xture.

A. Wrong Optima Plus ex tube diaphragm installed; i.e., 1.0 gpf

urinal installed on 3.5 gpf closet xture. Replace with proper

diaphragm assembly.

B. Enlarged by-pass in diaphragm. Replace with ex tube

diaphragm kit.

C. Control stop not adjusted properly. Readjust control stop.

D. Inadequate volume or pressure at supply. Increase water pressure

or supply ( ow) to valve. Consult factory for assistance.

8. Too much water to fi xture.

A. Control stop not adjusted properly. Readjust control stop.

B. Wrong Optima Plus ex tube diaphragm installed; i.e., 3.0 gpf model

installed on 1.0 or 1.5 gpf urinal xture. Replace with proper Optima

Plus diaphragm assembly.

C. Dirt in diaphragm by-pass. Clean under running water or replace

with new ex tube diaphragm.

9. Men’s room closet bowls unfl ushed.

A. Closet being used as urinal. Angle sensor slightly off xture

centerline to detect standing person in front of xture.

BATTERIES

When required, replace batteries with four (4) alkaline type AA batteries.

CARE AND CLEANING OF CHROME AND SPECIAL FINISHES

DO NOT USE abrasive or chemical cleaners to clean ushometers as they

may dull the luster and attack the chrome or special decorative nishes.

Use ONLY mild soap and water, then wipe dry with clean cloth or towel.

While cleaning the bathroom tile, the ushometer should be protected

from any splattering of cleaner. Acids and cleaning uids can discolor

or remove chrome plating.

When assistance is required, please contact

Sloan Technical Support at: 1-888-SLOAN-14 (1-888-756-2614).

TROUBLESHOOTING GUIDE

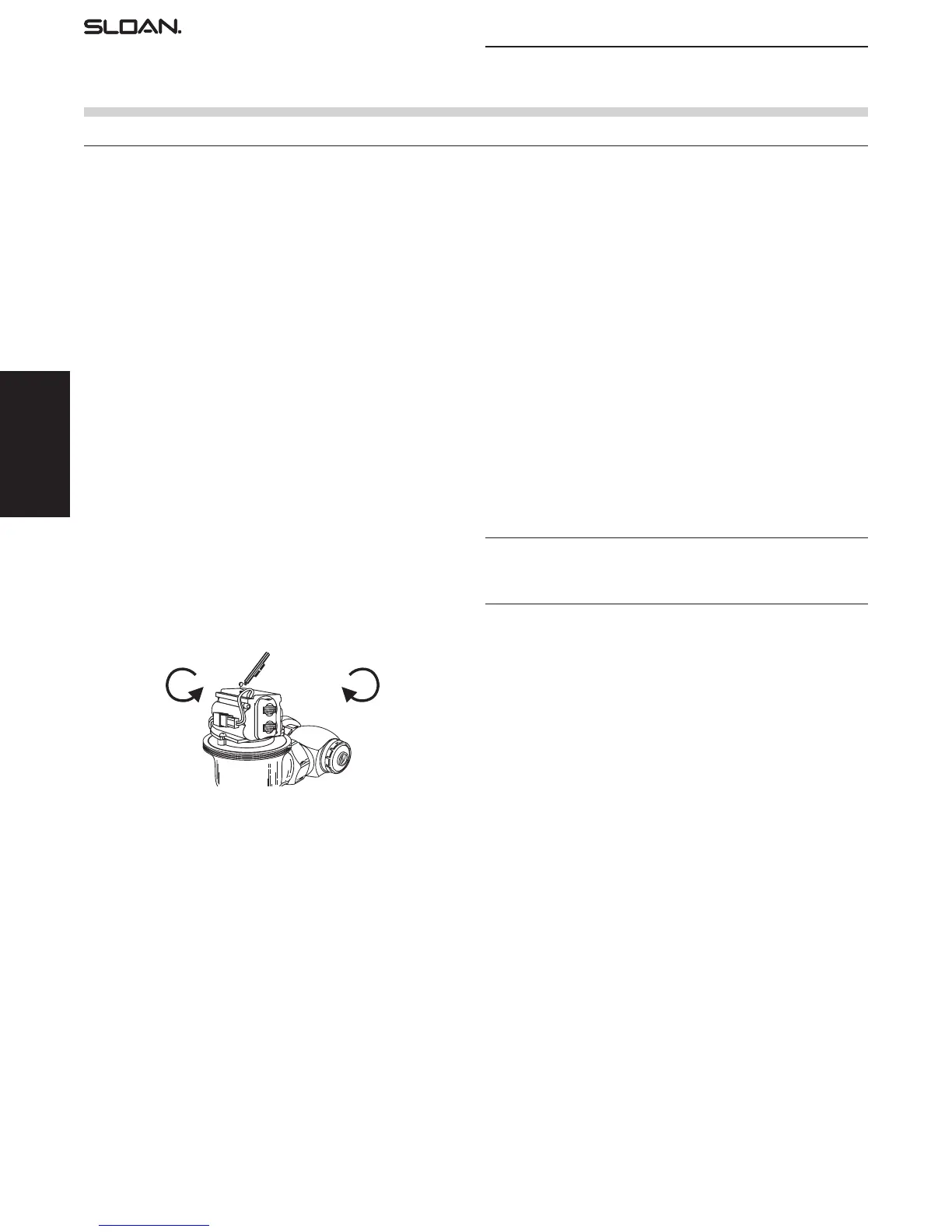

COUNTERCLOCKWISE

CLOCKWISE

Increases

Range

Repair Parts and Maintenance Guide

Optima

®

Flushometers

Repair Parts and Maintenance Guide

79

Sensor Flushometers

The information contained in this document is subject to change without notice.

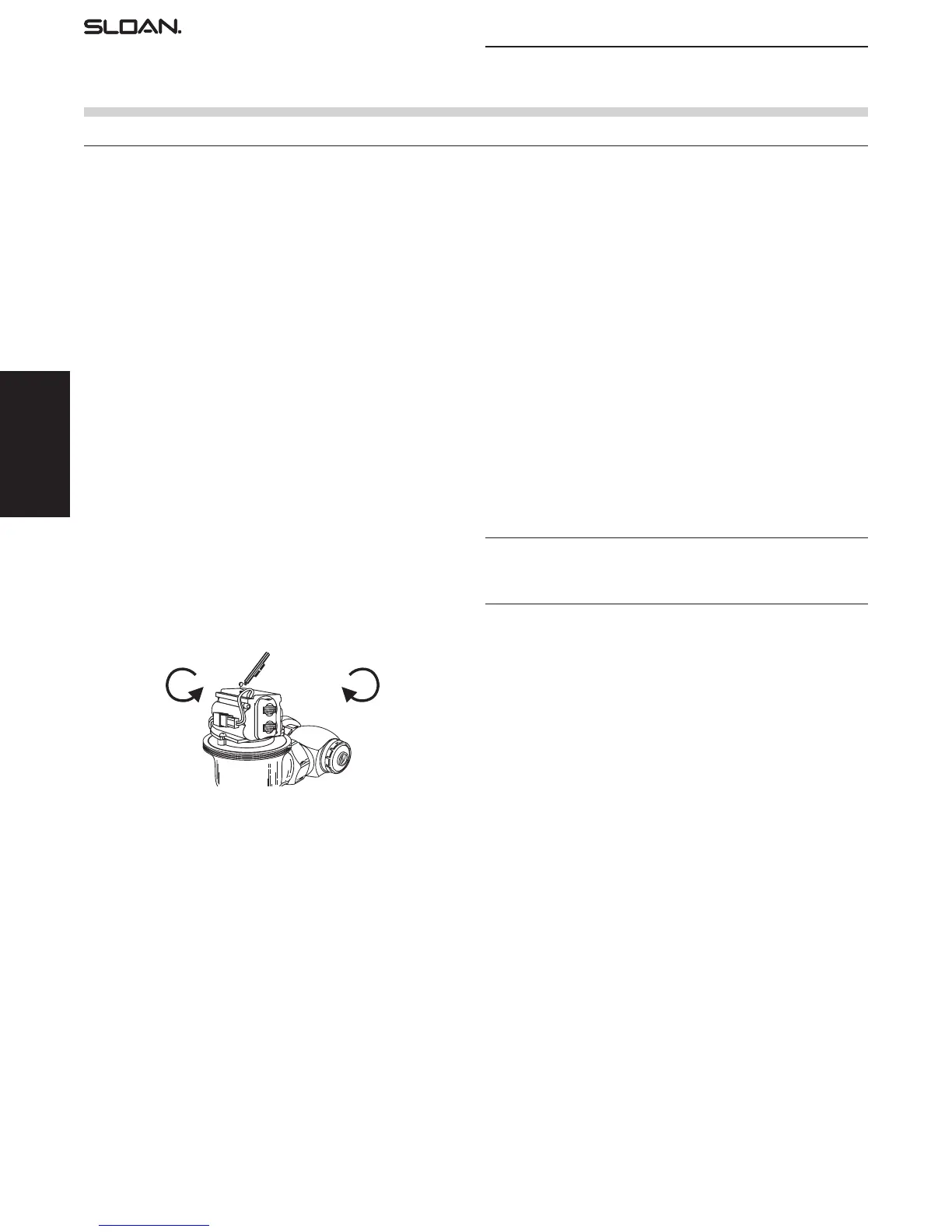

15

14

18A

2

18B 18C

19A

19B 19C

19D

19D 19D

3

1

5

8

7A

17

12

11

9

13

4

16

6

7

20

Repair Parts and Maintenance Guide

Optima

®

Sloan Flushometer

PARTS LIST

Item

No. Code No. Part No. Description

1. 0325298 EBV-189-A Cover/Ring/Sensor Assembly - Water Closet

0325299 EBV-190-A Cover/Ring/Sensor Assembly - Urinal

0325239 EBV-198-A Cover/Ring/Sensor Assembly - Water Closet

w/ Zurn ring

0325240 EBV-199-A Cover/Ring/Sensor Assembly - Urinal w/Zurn ring

2. 0325241 EBV-192-A Cover Assembly

3. N/A EBV-168 Locking Ring - Plastic inner cover only –

Use 3325089, EBV-1010-A

0305843 EBV-14 Locking Ring - Metal inner cover only

0305843 EBV-30-A Locking Ring - for Zurn valves

4. 3325450 EBV-129-A-C Electronic Module - Water Closet

3325451 EBV-129-A-U Electronic Module - Urinal

5. 3325089 EBV-1010-A Metal Inner Cover Repair Kit

Includes Items Nos. 3, 5, 6 and 7

6. 0325171 EBV-134 Cover Rest Plate

7. 3325453 EBV-136-A Solenoid

7A. 3325456 EBV-145-A Inside Cover Assembly (includes solenoid

EBV-136-A) Does not replace Plastic Inner Cover.

Use Item No. 5

8. SEE CHART NEXT PAGE Flex Tube Diaphragm Assembly

9. SEE CHART NEXT PAGE Flush Volume Regulator

10. 3325814 EBV-1017 Handle Cap Kit

11. 0325107 EBV-91 Range Adjustment Tool

12. 0305823 EBV-22 Strap Wrench

13. 0325159 EBV-137 7/64” Hex Wrench

14. 3308785 H-634-AA 1” (25 mm) Sweat Solder Kit

3308788 H-636-AA 3/4” (19 mm) Sweat Solder Kit

15. 3308386 H-700-A 1” (25 mm) Bak-Chek

®

Control Stop

3308384 H-700-A 3/4” (19 mm) Bak-Chek

®

Control Stop

16. 3308840 H-573-A Stop Cap

17. 0305381PK EBV-36-A Valve Body *

18A. 5323007 V-500-AA 1-1/2” (38 mm) x 9” (229 mm) Vacuum Breaker

(Model 8110/8111)

0323014 V-500-AA 1-1/2” (38 mm) x 13 1/2” (343 mm) Vacuum

Breaker (Model 8113)

0323019 V-500-AA 1-1/2” (38 mm) x 23” (584 mm) Vacuum Breaker

(Model 8115)

0323021 V-500-AA 1-1/2” (38 mm) x 26” (660 mm) Vacuum Breaker

(Model 8116)

18B. 5323006 V-500-AA 1-1/4” (32 mm) x 9” (229 mm) Vacuum Breaker

(Model 8180)

18C. 5323005 V-500-AA 3/4” (19 mm) x 9” (229 mm) Vacuum Breaker

(Model 8186)

19A. 0306145 F-56-A 1-1/2” Spud Coupling Assembly

(Models 8110, 8115 & 8116)

19B. 0306142 F-55-A 1-1/4” Spud Coupling Assembly (Model 8180)

19C. 0306102 F-54-A 3/4” Spud Coupling Assembly (Model 8186)

19D. SEE SLIP JOINT GASKETS AND RINGS TABLE ON NEXT PAGE

20. 3323192 V-551-A Vacuum Breaker Repair Kit

* Part number varies with valve model variation; consult factory.

Earlier model with

A-3 body

A-3 Body

10

10

372626_Master_Book_ccg.indd 76 9/18/17 7:52 AM

Loading...

Loading...