Do you have a question about the Sony Discman D-50MkII and is the answer not in the manual?

Technical specifications for the CD player, including system and performance details.

Important safety precautions regarding radiation and critical components.

Description of product features and instructions for cleaning and upkeep.

Guide to resolving common problems like disc playback and sound issues.

Recommendations for proper handling and care of compact discs.

Proper procedures for handling the optical pick-up block and grounding to prevent static damage.

Explanation of 2-letter, 3-number, and 4-letter coding systems for chip components.

Guidance on safely replacing chip components, including removal and connection steps.

Procedures for repairing flexible circuit boards and soldering iron tip maintenance.

Diagram illustrating the layout of PC boards, switches, and motors within the unit.

Flowchart detailing the service program execution and logic for diagnostics.

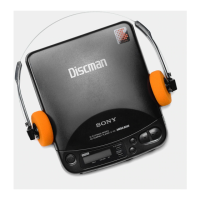

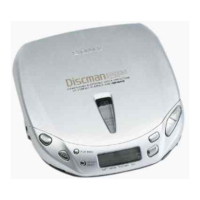

Description of front/rear controls, display window, and play mode indicators.

Instructions on how to recharge the rechargeable battery pack.

Procedures for stopping, pausing playback, and utilizing the time counter.

Using AMS and Search functions to locate selections or specific points on the disc.

Instructions for repeat play, AB repeat, shuffle play, and RMS custom order playback.

Detailed circuit description of the 4-bit microcomputer system and its functions.

Flowchart detailing the service program execution and logic.

Procedure for checking the battery charging circuit.

Step-by-step disassembly instructions and notes on handling mechanical parts.

Reassembly steps for spindle motor, flexible board, and sled motor sections.

Procedures for oiling shafts, replacing FOP, and reassembling the feed rack.

Detailed steps for disassembling and installing the optical pick-up block.

Procedures for adjusting turntable height and feed screw thrust for optimal operation.

General notes, preparation, and checks for sled motor and focus search.

Procedures for PLL frequency check/adjustment and focus bias adjustment.

Description and diagram of the expected RF signal eye pattern.

Conditions and step-by-step procedure for adjusting tracking balance.

Conditions and procedure for checking and adjusting sled motor offset.

Procedure and method for adjusting tracking gain using VR control.

Connecting point for 2.5V reference and references to related adjustment sections.

Diagrams showing lead layouts for various semiconductor components.

Notes on schematic symbols, units, and supply status of mechanical parts.

List of switches and details on mechanical parts and components.

Detailed list of all parts with part numbers, descriptions, and remarks.

Lists chassis types for SL-C/710/711 models in NTSC and CCIR systems.

Terminology for tape guides and preparation steps for NTSC tape path adjustment.

Procedure for adjusting entrance side guides for proper tape path alignment.

Procedure for adjusting exit side guides and ACE head for proper tape path.

Procedures for adjusting audio head azimuth and CTL head position.

Details on mechanical and electrical adjustment of the ACE assembly.

Procedure for adjusting audio head height if necessary.

Procedure to check the self-recorded RF output waveform.

Procedure to check and match CH-A and CH-B RF output levels.

Terminology for tape guides and preparation steps for 711 CCIR tape path adjustment.

Procedure for adjusting entrance side guides for proper tape path alignment.

Procedure for adjusting exit side guides and checking for tape curl and space.

Procedures for adjusting audio head azimuth and CTL head position.

Details on mechanical and electrical adjustment of the ACE assembly.

Procedure for adjusting audio head height if necessary.

Procedure to check the self-recorded RF output waveform.

Procedure to check and match CH-A and CH-B RF output levels.

Terminology for tape guides and preparation steps for 711 NTSC tape path adjustment.

Adjusting exit side guides and checking for tape curl and space.

Procedure to check for tape damage on the S reel.

Procedures for adjusting audio head azimuth and CTL head position.

Adjusting tracking control center and CTL head position.

Procedure for adjusting audio head height if necessary.

Procedure to check the self-recorded RF output waveform.

Procedure to check and match CH-A and CH-B RF output levels.

Terminology for tape guides and preparation steps for 711 CCIR tape path adjustment.

Procedure for adjusting entrance side guides for proper tape path alignment.

Adjusting exit side guides and checking for tape curl and space.

Procedure to check for tape damage on the S reel.

Procedures for adjusting audio head azimuth and CTL head position.

Procedure for adjusting audio head height if necessary.

Procedure to check the self-recorded RF output waveform.

Procedure to check and match CH-A and CH-B RF output levels.

Corrections for sled motor offset adjustment and mounting diagrams on pages 9, 37, 38.

Procedure for checking the battery charging circuit functionality.

| Type | Portable CD Player |

|---|---|

| Model | D-50MkII |

| Brand | Sony |

| Frequency response | 20 Hz - 20 kHz |

| Signal to Noise Ratio | 90 dB |

| Anti-Skip Protection | Yes |

| Dynamic Range | 90 dB |

| Disc format | CD |

| Digital converter | 1-bit |

| Power Supply | AA batteries or AC adapter |

| Output | Headphone and Line Out |

Loading...

Loading...