6

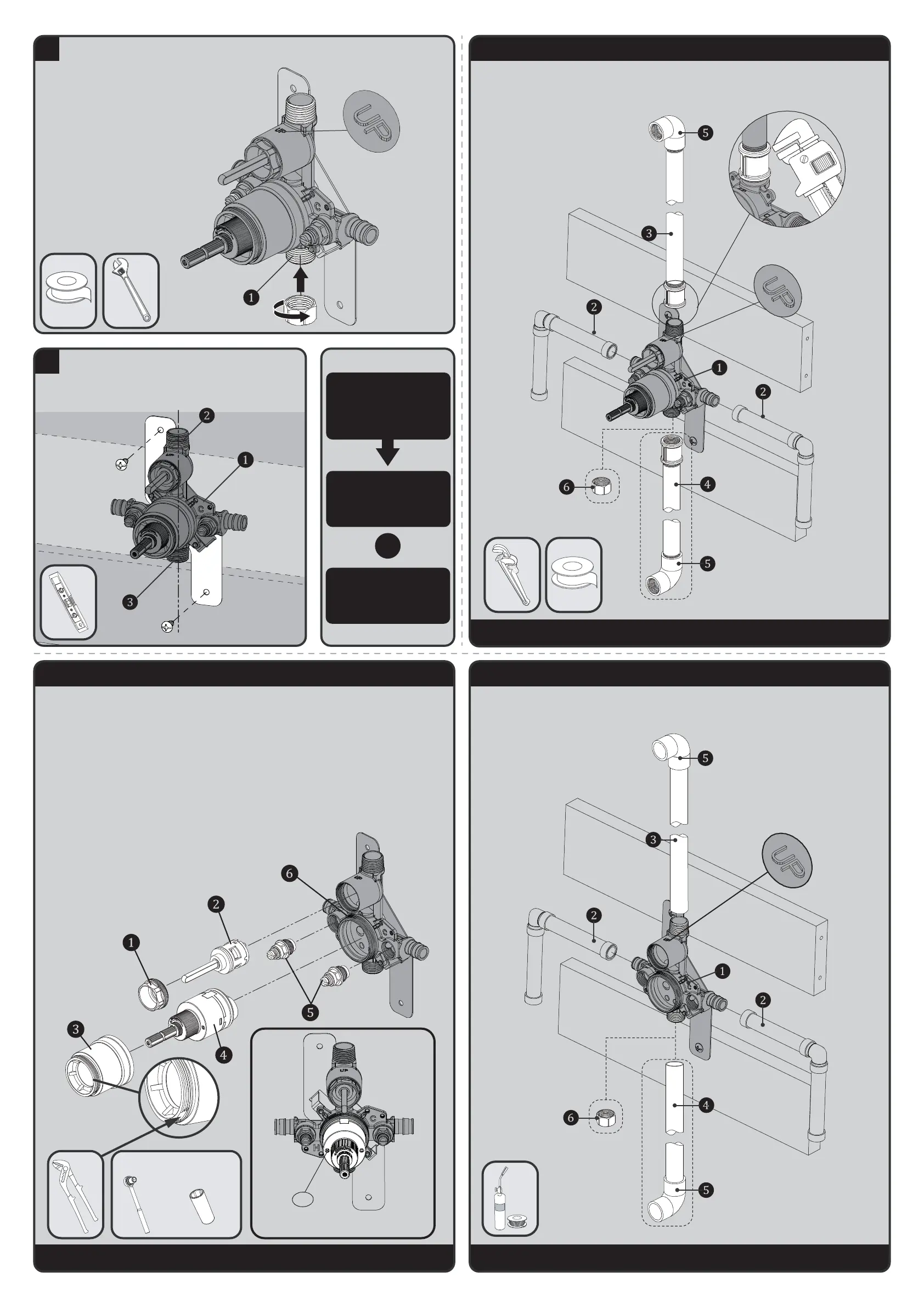

If your installation is for a shower only, apply Thread Seal Tape in a clockwise direction to the Tub Outlet Port ❶

and install the included Plug Cap. Wrench tighten. If you are performing a pipe fitting installation, apply Thread

Seal Tape around the pipe threads in a clockwise direction.

7

Referencing the Rough-In Drawing, mount the Valve Assembly ❶ to

structure within the wall. Ensuring the Shower Outlet ❷ and Tub

Outlet ❸ are positioned perfectly vertical. Mounting Hardware and

Mounting Structure must be capable of supporting the Valve in use.

Mounting hardware is not included.

If you are performing a

Pipe Fitting Outlet

Installation, please

proceed to Step 8.

OR

If you are performing a

Copper Sweat Outlet

Installation, please

proceed to Step 9.

IMPORTANT:

Install all outlet connections

(Pipe or Copper Sweat)

PRIOR to installing PEX

inlet connections.

8 PIPE FITTING INSTALLATION

Connect the Shower Outlet Pipe ❸ (not included), and Tub Outlet Pipe ❹ (not included), by threading them into

the Valve Body ❶ in a clockwise direction. Tighten the pipes to the Valve Body ❶ with a Pipe Wrench. Connect

the Pipe Elbows ❺ (not included), to the end of the shower outlet and tub outlet pipes. If performing a shower

only installation, install Plug Cap ❻ in place of tub outlet piping, as shown in STEP 6.

NOTE: The HOT water supply lines go into the H inlet, and the COLD water supply lines

go into the C inlet. Do not use PEX or CPVC between the valve and spout.

SHOWER ONLY

TUB + SHOWER

COLD

HOT

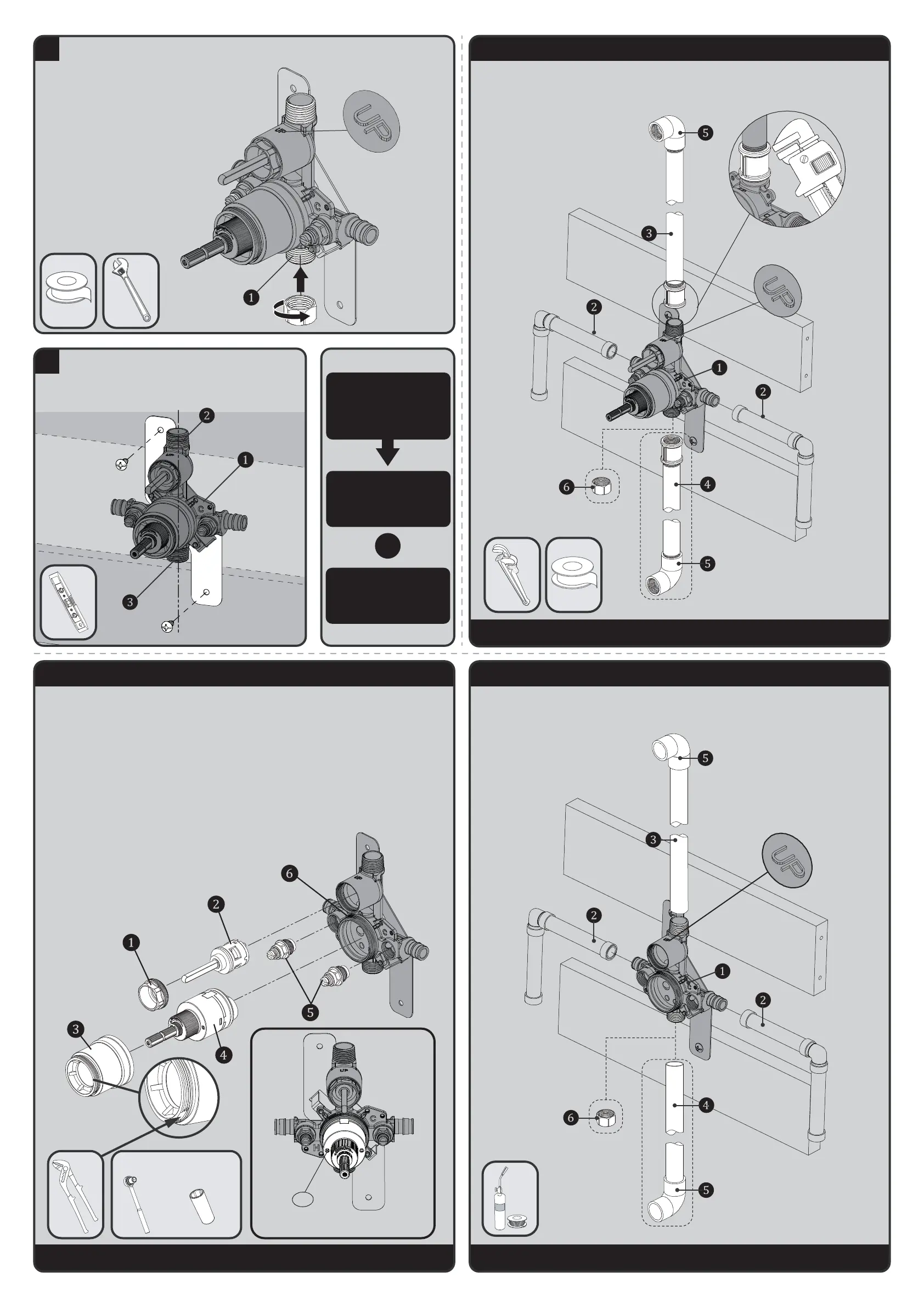

9 COPPER SWEAT INSTALLATION

When performing a Copper Sweat installation, it is recommended that you remove the Valve Cartridge ❹, Integral Stops

❺, and Diverter Cartridge ❷ (where applicable) to prevent damage during soldering. Use a Slip Joint Wrench to

unthread and remove the Bonnet ❸. Then remove Valve Cartridge ❹, from Valve Body ❻. Unthread and remove the

Integral Stops ❺ using a Socket Wrench equipped with a 9/16” (14mm) Deep Well Socket. If your Shower Valve is

equipped with an Integral Diverter, remove the Diverter Retaining Nut ❶ using an Adjustable Wrench. Remove Diverter

Cartridge ❷ to prevent damage during soldering.

After soldering (STEP 10) is completed, reinstall the Valve Cartridge ❹, making sure that the mounting posts are aligned

and engaged to the corresponding holes in the Valve Body ❻, with the “H” marking to the left side as shown below.

Slide Bonnet ❸ over the Valve Cartridge ❹ and thread onto the Valve Body ❻. Tighten securely with Slip Joint Wrench

on the machined flats of the Bonnet ❸. Final torque should be 88-106 in*lb. Take care to not over tighten connection or

damage may occur. Reinstall the Integral Stops ❺ using a Socket Wrench equipped with a 9/16” (14mm) Deep Well

Socket. Final torque should be 70-106 in*lb. If your Shower Valve is equipped with an Integral Diverter, reinstall the

Diverter Cartridge ❷ taking care to align mounting posts of Cartridge with the corresponding holes in the Diverter Valve

Body. Install Diverter Retaining Nut ❶ and tighten with an Adjustable Wrench. Final torque should be 35-53 in*lb. Take

care to not over-tighten connections.

NOTE: Never install the valve body upside down!

Socket

Wrench

9/16” (14mm) Deep

Well Socket

+

Normal Installation

(shown without Bonnet)

H

10 COPPER SWEAT FITTING INSTALLATION

Connect the Shower Outlet Pipe ❸ (not included), and Tub Outlet Pipe ❹ (not included), by soldering them into

the Valve Vody ❶. Connect the Pipe Elbows ❺ (not included), to the end of the shower outlet and tub outlet

pipes. If performing a shower only installation, install Plug Cap ❻ in place of tub outlet piping, as shown in

STEP 6. Verify that all connections are soldered. Reassemble Valve components as outlined in STEP 9.

NOTE: The HOT water supply lines go into the H inlet, and the COLD water supply lines

go into the C inlet. Do not use PEX or CPVC between the valve and spout.

SHOWER ONLY

TUB + SHOWER

COLD

HOT

Loading...

Loading...