PEX (COLD EXPANSION) INSTALLATION INSTRUCTIONS

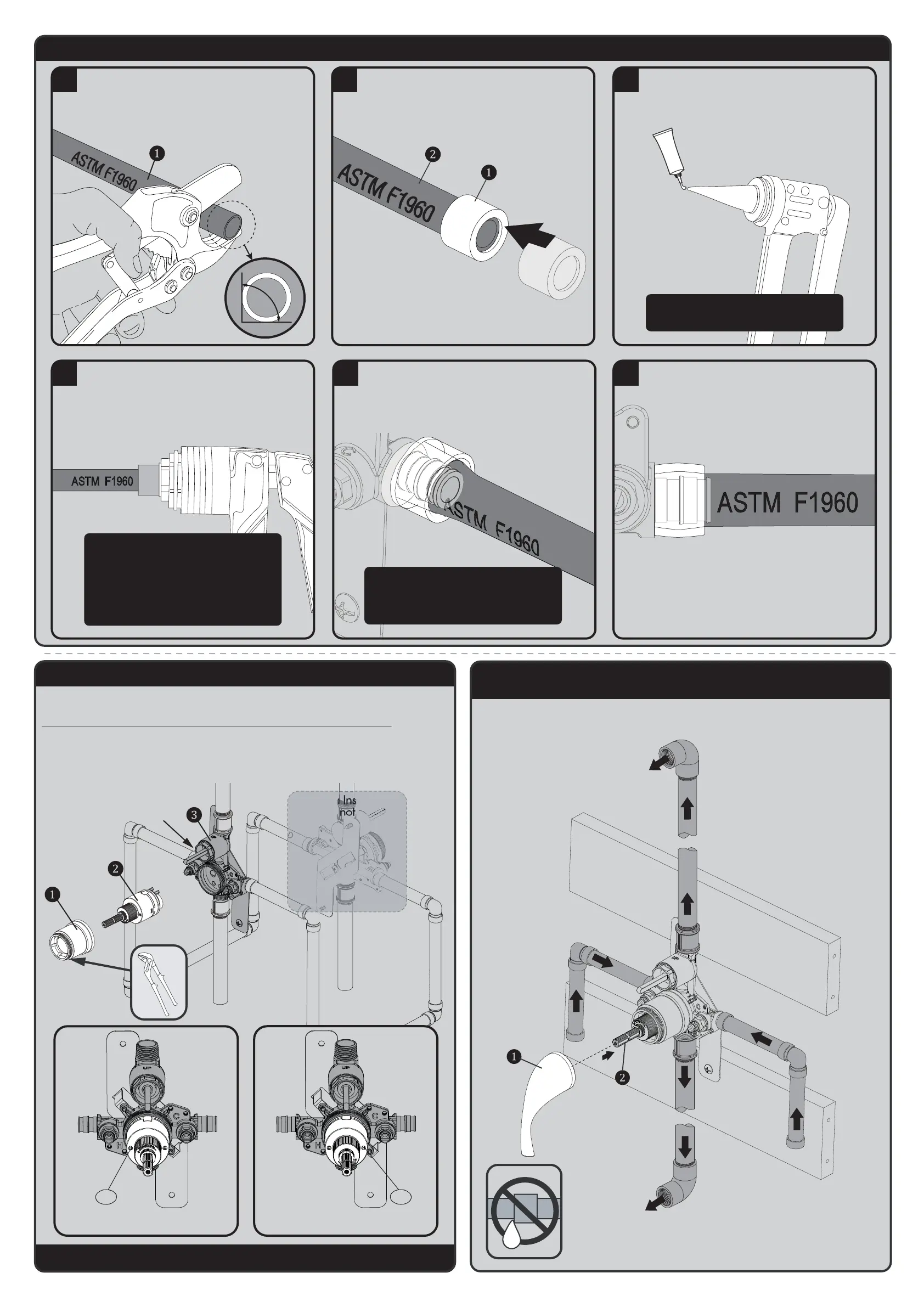

F

Verify that the connection is complete and is secure.

E

After the final expansion, immediately remove the tool and insert

the expanded tube and sleeve onto the PEX barb of the Valve until

it touches the shoulder. Assure proper expansion so that PEX barb

is touching the inside diameter of tube and sleeve. Hold the Valve

in place until tube and sleeve memory constrict annularly around

the PEX barb.

NOTE: Some resistance may be felt as the PEX barb

slides into the expanded tube and sleeve. If no

resistance is felt, then the tube and sleeve may have

been over expanded and will require additional time

to shrink over the PEX barb.

D

Slide the tube and sleeve onto the tapered end of the expansion

head as far as possible without forcing. Expand the tube and

sleeve by closing the handles of the tube expander tool. Release

the handles and allow the head to contract. Repeat expansions

by removing the head from the tubing, rotating expander

1/8-turn, and sliding the head back into the tubing. Failure to

rotate the tool between expansions may cause uneven

expansion of the tube and sleeve and can create a leak path.

NOTE: The number of expansion cycles will

vary with the size of the connection and

installation temperature. To limit the amount of

time for tube and sleeve compression onto PEX

barb in cold environments, expand the tube and

sleeve slowly and only enough to fully insert the

PEX barb. Keeping sleeves warm will speed

retraction and inhibit unequal expansion.

C

Use ASTM F1960 Grip Expansion Tool for expanding PEX tube

and sleeve together. Before installing the appropriate size

expansion head on the tube expander tool, add lubricant lightly

to the cone of the tool if needed. Do not allow lubricant to coat

the inside of the pipe.

NOTE: Lubrication between the expanding cone of

the tool and the expansion head is necessary to

prevent excessive wear.

B

Slide the correct size i.e., ½” ASTM F1960 compliant PEX Sleeve

❶ (not included) on to the Outside Diameter of ½” PEX Tubing ❷

(not included), until it reaches the stop edge. If the Sleeve is

without a stop edge, then extend the Sleeve over the end of the

tubing no more than 1/16”.

A

Use Plastic Tubing Cutters (not included), to cut the ASTM F1960

compliant PEX Tubing ❶ to length. Ensure that a good square (90°)

cut is obtained. A rough or uneven cut will result in a weakened

joint. Do not crush Outer Diameter of tubing with cutters.

Note: Slightly rotate cutter during blade engagement.A rough or

uneven cut will result in a weakened joint.

90°

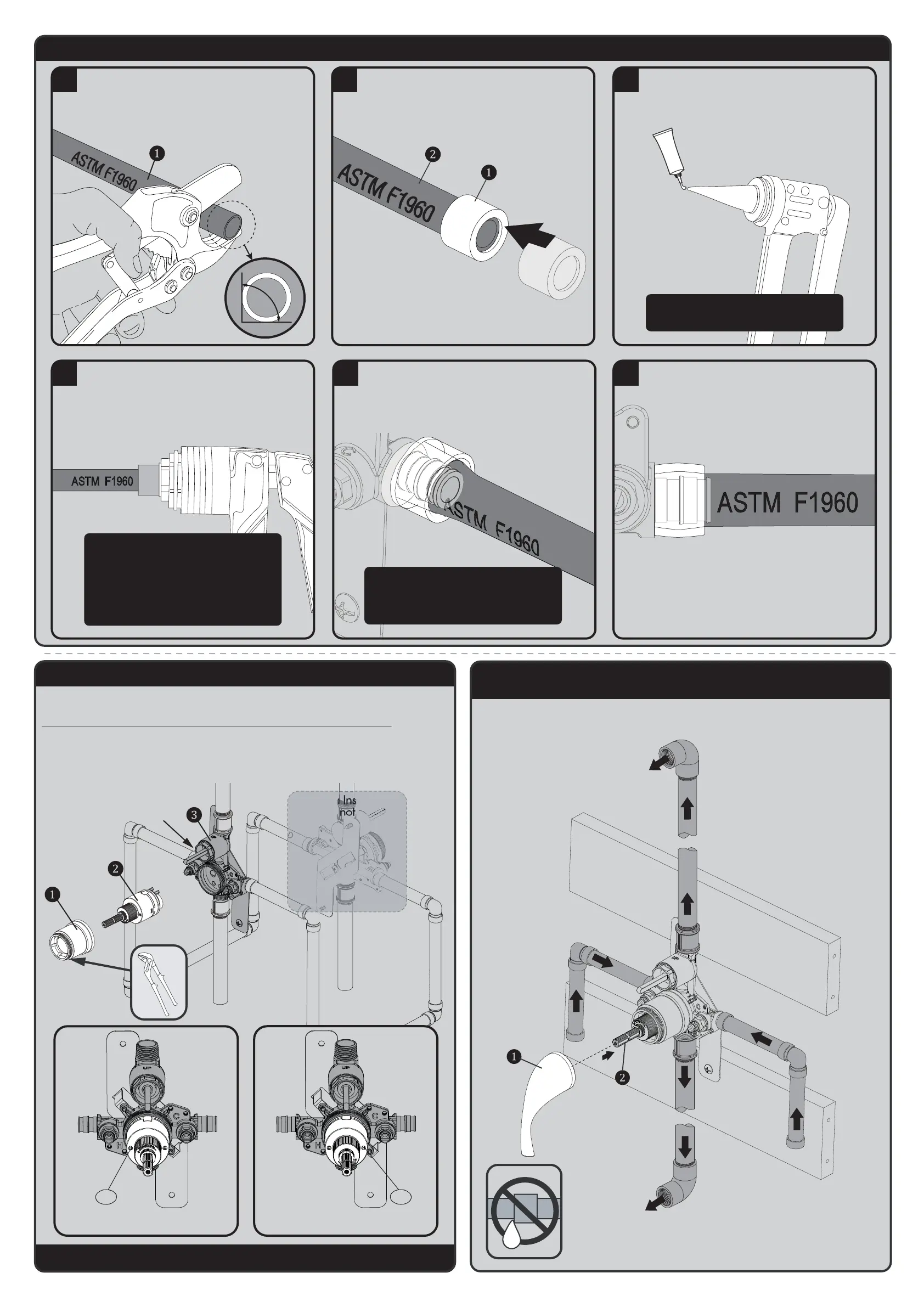

11 BACK-TO-BACK INSTALLATION

Your Shower Valve has the ability to be mounted back-to-back with another Valve in a shared space. This means the HOT

and COLD inlets may be reversed. Please see the following steps to adapt your valve for back-to-back mounting or

reversed inlet supplies.

If you are NOT making a reverse or back-to-back installation, skip this step, and continue with STEP 12. If the HOT and

COLD water supplies are reversed (HOT on right and COLD on left), disassemble Valve Cartridge as outlined in STEP 9.

Rotate Valve Cartridge ❷ 180° so “H” appears on the right. Install the Valve Cartridge ❷ making sure that the

mounting posts are aligned and engaged to the corresponding holes in the Valve Body ❸. Slide Bonnet ❶ over the

Cartridge and thread onto the body. Tighten securely with Slip Joint Wrench on the machined flats of the Bonnet ❶. Final

torque should be 88-106 in*lb. Take care to not over tighten connection or damage may occur.

NOTE: Never install the valve body upside down!

Reverse

Installation

COLD

COLD

COLD

COLD

COLD

HOT

HOT

HOT

HOT

Normal Installation

(changes not required)

Normal Installation

(shown without Bonnet)

H

Reverse Installation

(shown without Bonnet)

H

12

FLUSHING THE WATER OUTLETS

AND CHECKING FOR LEAKS

Place the Handle ❶ on the Valve Cartridge Spindle ❷ and turn the Handle ❶ clockwise to the full on mixed position.

Turn on the HOT and COLD water supply lines and allow the water to flow from the outlets for one minute, or until all

foreign matter has been flushed out. Check for leaks. Shut off the water at the Valve and supply lines. Remove the

Handle ❶.

Loading...

Loading...