Instruction and Operation Manual

-

-

portable no-Ex-proof electrical device in the area and do not use open fire without a valid work

permit

.

2.2.1.9

Valve must periodically checked on:

-Tightness of bolted connection (body/bonnet, gland, flange connection).

-Corrosion/wear damages (crack, pitting, thickness of the valve).

-Make sure the valves are in fully open/fully closed position.

2.2.2

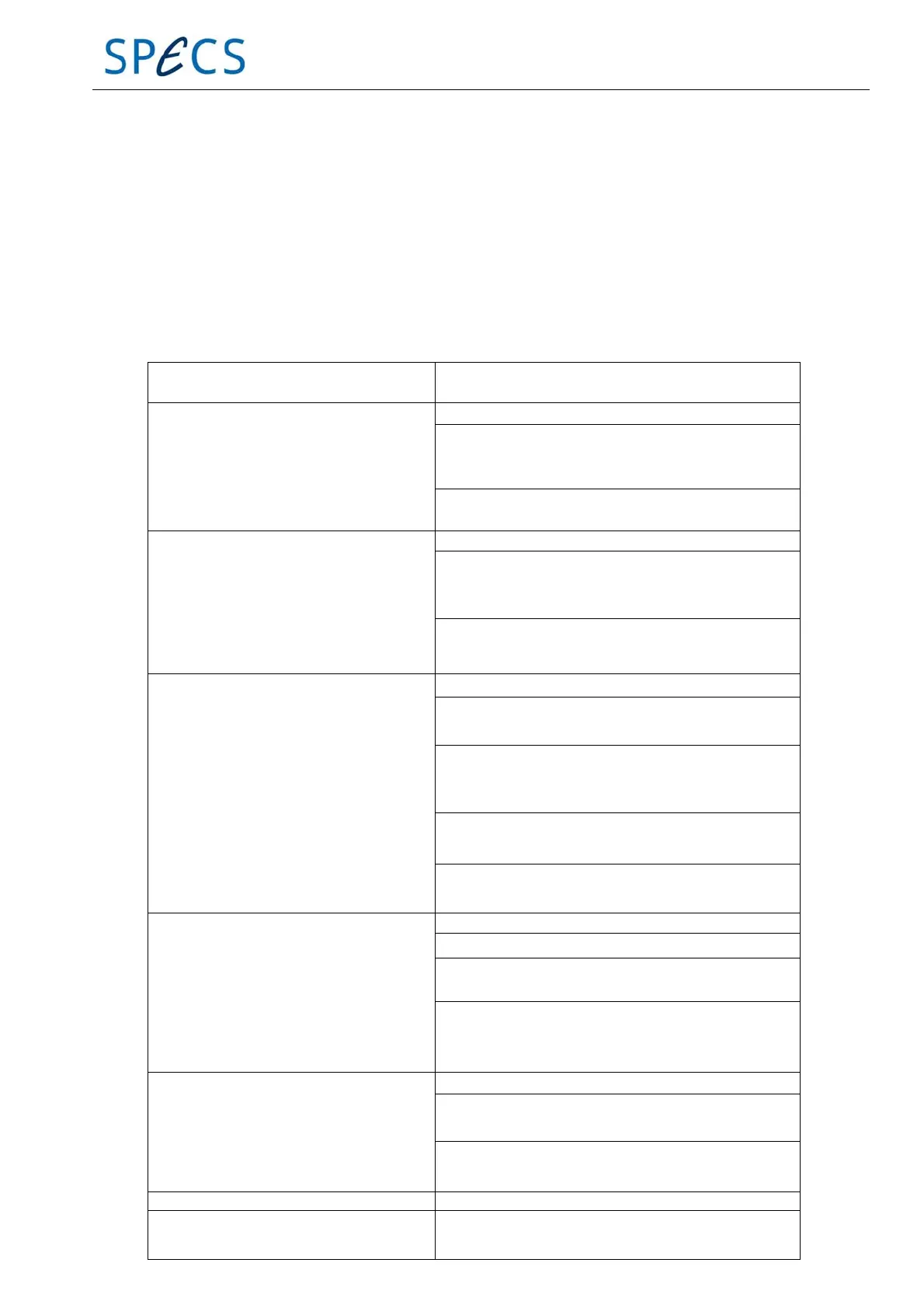

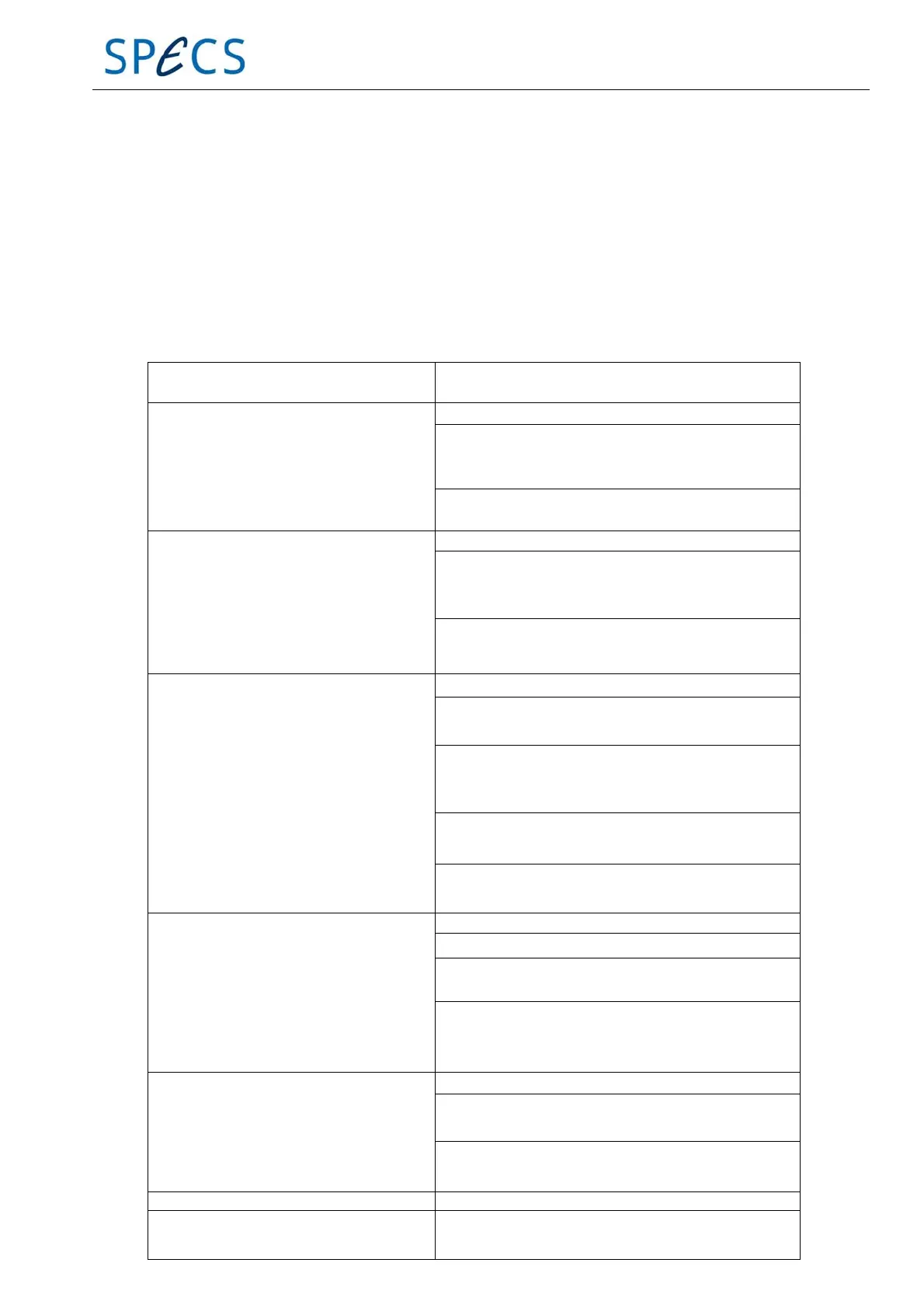

Specifics

Risk

Preventive Action

Accidental contact with dangerous

service fluid*

Due to

: Gasket or Packing Blow out

1

. See 2.2.1 General

2. Immediately replace Gasket and packing

after a Blow-out

(use approved/suitable

materials only

3. Use recommended torque as in Table 5 and

Table 6

Accidental contact with dangerous

service fluid* during disassembly or

maintenance operations

1

. See 2.2.1 General

2. After removal from the production line, open

and close valve to guarantee depressurized

cavity

.

3. Drain any remainder fluid or substances with

suitable devices before disassembly

.

Structural yielding of valves body

with consequent risk of contact with

dangerous service medium*

,

explosion or fire

1

. See 2.2.1 General

2. Create precautions to avoid additional forces

on the valves

3. Avoid absolutely water hammer: install

precaution devices if necessary

(e.g. brakes,

anti shock devices, etc.)

4. Avoid submitting excessive vibrations to the

valves

.

5. Avoid quick Pressure and/or Temperature

deviations

.

Accidental contact with High or Low

temperature parts

1

. See 2.2.1 General

2. Predispose apposite insulation on the valve.

3. Alert by means of warning signs about risk of

burns

.

4. For Cryogenic-/High Temperature service

use only valves equipped with Cryogenic-/High

Temp

. Extension.

Fire or explosion in case of service

with flammable fluids

1

. See 2.2.1 General

2. Install only Ex-proof electrical devices in the

area

3. While performing maintenance in the area,

shut down all electrical devices.

Explosion in case of oxygen service 1. See 2.2.1 General

2

. Install only Ex-proof electrical devices in the

area

Loading...

Loading...