Cleaning the sample compartment

~

~In the event a test tube breaks in the sample

compartment, it is important to remove the glass and

any spilled liquid as soon as possible.

@-i

.kJ...ll

~

~

vAI.

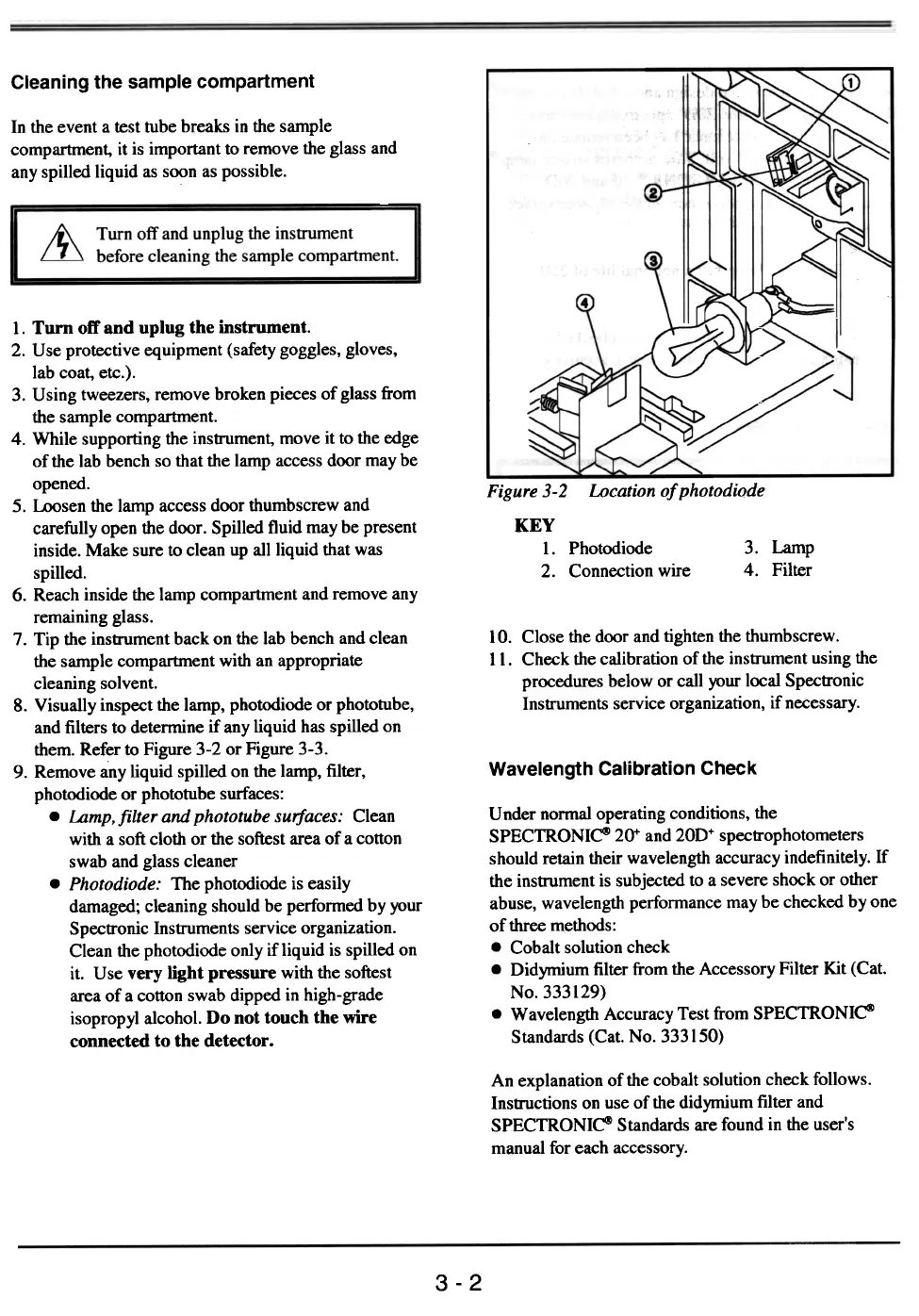

Figure 3-2 Location of photo diode

KEY

1. Photodiode

2. Connection wire

3. Lamp

4. Filter

10.

Close the door and tighten the thumbscrew.

11. Check the calibration of the insuument using the

procedures below or call your local Spectronic

Insuuments service organization, if necessary.

Wavelength Calibration Check

1. Turn off and uplug the instrument.2.

Use protective equipment (safety goggles, gloves,

lab coat, etc.).

3. Using tweezers, remove broken pieces of glass from

the sample compartment.4.

While supporting the instrument, move it to the edge

of the lab bench so that the lamp access door may be

opened.

5. Loosen the lamp access door thumbscrew and

carefully open the door. Spilled fluid may be present

inside. Make sure to clean up all liquid that was

spilled.6.

Reach inside the lamp compartment and remove any

remaining glass.

7. Tip the instrument back on the lab bench and clean

the sample compartment with an appropriate

cleaning solvent.

8. Visually inspect the lamp, photodiode or phototube,

and filters to determine if any liquid has spilled on

them. Refer to Figure 3-2 or Figure 3-3.

9. Remove any liquid spilled on the lamp, filter,

photodiode or phototube surfaces:

.Lamp, filter and phototube surfaces: Clean

with a soft cloth or the softest area of a cotton

swab and glass cleaner

.Photodiode: The photodiode is easily

damaged; cleaning should be performed by your

Spectronic Instruments service organization.

Clean the photodiode only if liquid is spilled on

it. Use very light pressure with the softest

area of a cotton swab dipped in high-grade

isopropyl alcohol. Do not touch the wire

connected to the detector.

Under nonnal operating conditions, the

SPECTRONI~ 20+ and 20D+ spectrophotometers

should retain their wavelength accuracy indefinitely. If

the instrument is subjected to a severe shock or other

abuse, wavelength performance may be checked by one

of three methods:

.Cobalt solution check

.Didymium filter from the Accessory Filter Kit (Cat.

No. 333129)

.Wavelength Accuracy Test from SPECTRONIC'I

Standards (Cat. No. 333150)

An explanation of the cobalt solution check follows.

Instructions on use of the didymium filter and

SPECTRONIC!> Standards are found in the user's

manual for each accessory.

3-2

Loading...

Loading...