operation before being returned to

service. Only parts manufactured by

Emerson should be used for repairing

this pilot.

Due to normal wear or damage that may

occur from external sources, this pilot

should be inspected and maintained

periodically. The frequency of inspection

and replacement of parts depends upon

the severity of service conditions or the

requirement of local, state and federal

rules and regulations.

Disassembly

1. Release adjusting spring (key 4) compression by

loosening adjusting nuts (key 1). Remove nuts,

yoke (key 2), adjusting spring and spring button

(key 5).

2. Remove diaphragm nuts (key 15) and lift off cowl

(key 6). Lift out diaphragm assembly (keys 7, 16

and 17).

3. Disassemble diaphragm assembly by removing

diaphragm screw (key 7) from pressure plate

(key 16).

Note

This step is not necessary if installing

a new diaphragm assembly (included in

repair kit).

4. Remove blind flange bolts (key 23) and take off

blind flange (key 14). Remove screen (key 20) and

gasket (key 13).

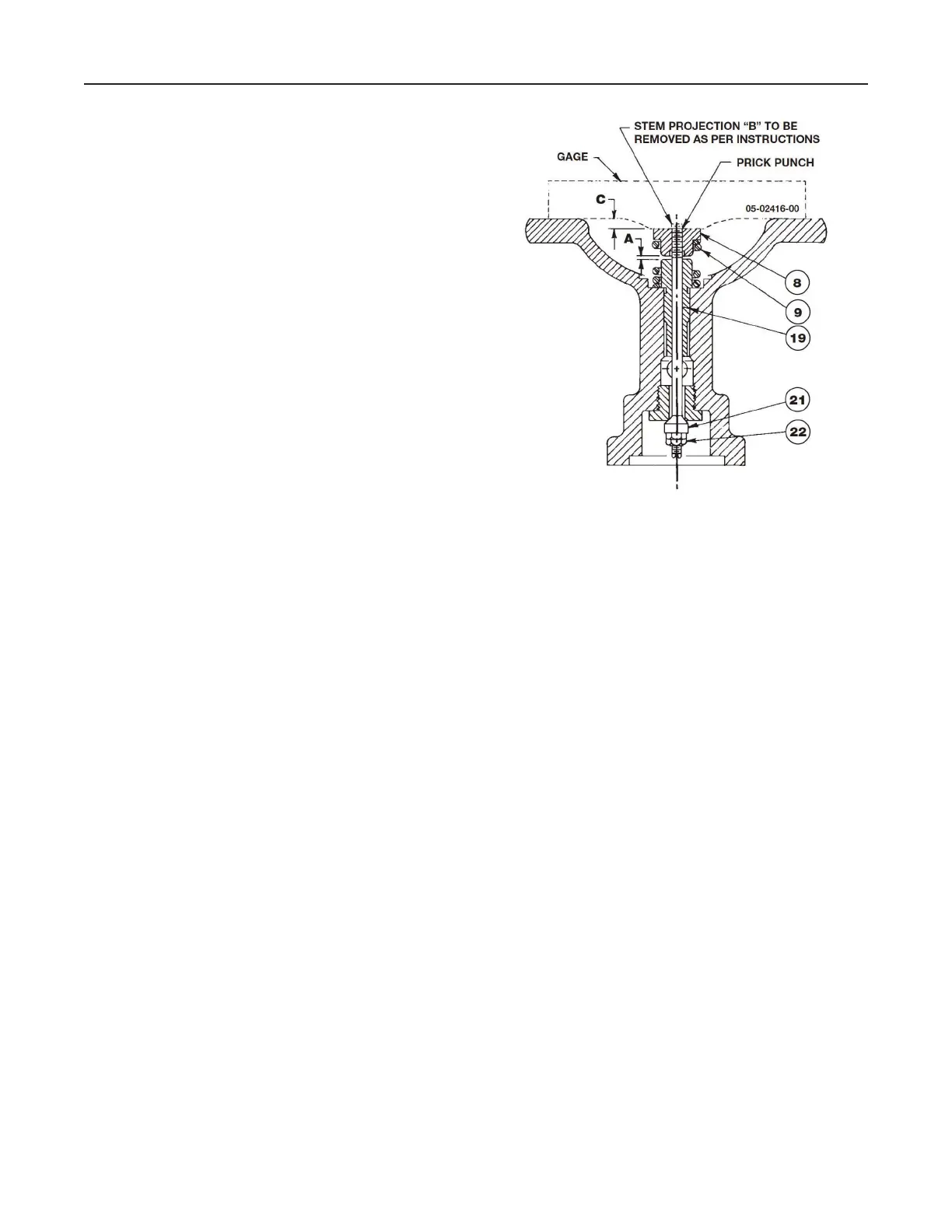

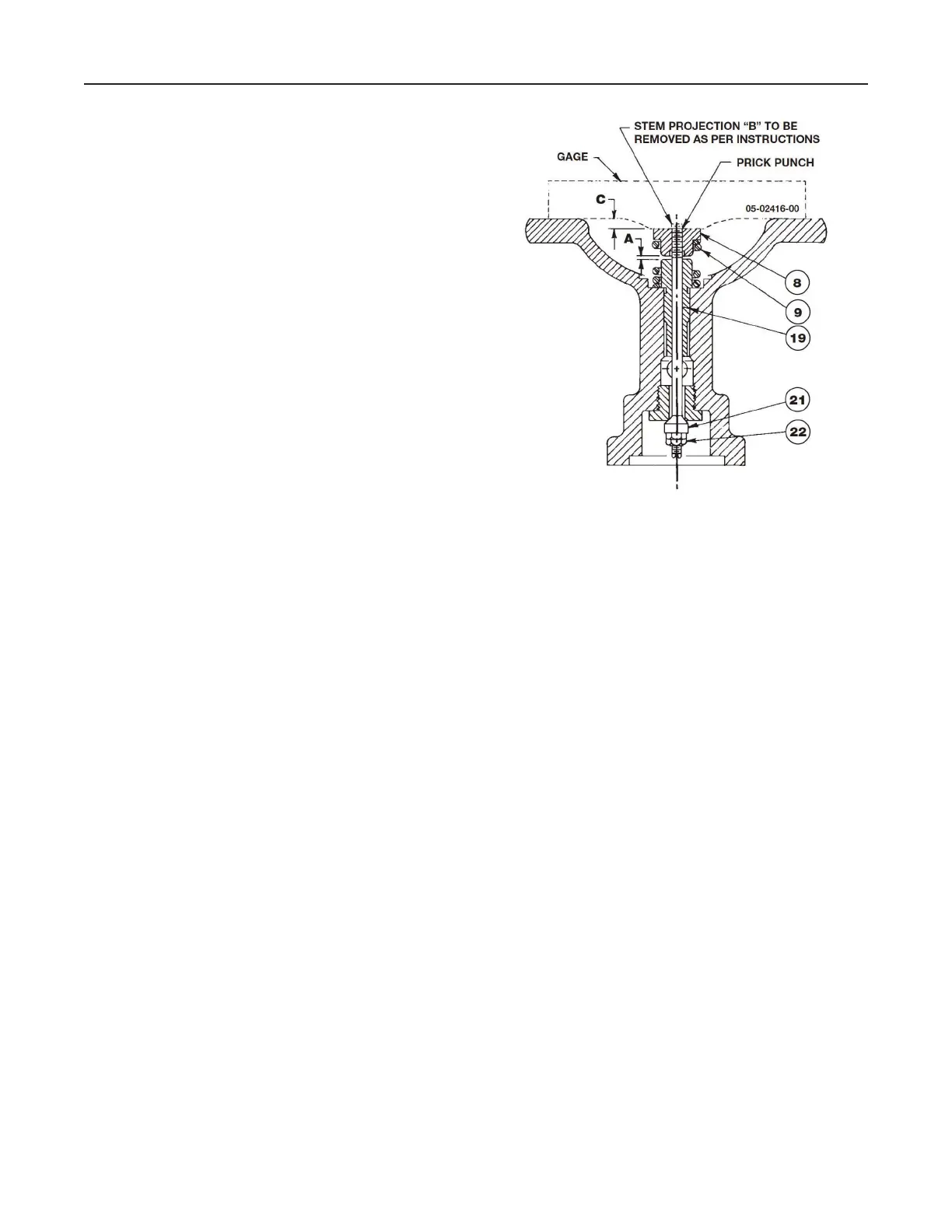

5. Hold the pusher plate (key 8) and remove stem

nuts (key 22). Lift out stem assembly (keys 8 and

19) and valve spring (key 9). The disk (key 21)

will drop off. If the disk is not easily removed from

the stem, or the stem does not easily move in the

bushing (key 10) is difficult to remove, inspect

stem, seat ring (key 11) and disk carefully for

notches, scratches or bending.

6. Remove the seat ring (key 11) from the pilot body

(key 12) using a socket wrench. Do not remove

the seat ring unless replacing the stem assembly

(keys 8 and 19) and disk (key 21).

Inspection

1. Examine the seat ring (key 11) and disk (key 21)

sealing surfaces for nicks or other signs of

damage by pipeline debris. Slight imperfections

may be removed by lapping the surfaces.

Otherwise, replace the seat ring and disk.

2. Examine the stem (key 19) for a build-up of

pipeline contaminants or erosion. Remove any

build-up with a wire brush and polish with a very

fine crocus cloth. Work carefully to avoid bending

the stem.

3. Inspect the pilot body (key 12) and its ports for

corrosion. Some rust is normal, but if corrosion

debris is readily separated from the body, clean

body with wire brush and remove debris.

Lapping Operations

Lap sparingly using 500 grit lapping compound and

light pressure. Heavy grinding may cause galling, wide

sealing surfaces and a groove disk, all of which tend to

produce leakage.

Lapping may be done using a socket wrench to rotate

the stem and disk assembly back and forth against the

seat for 30 seconds or so. After the sealing surfaces

are lapped in, disassemble and clean all parts.

Seat, Disk and Stem Replacement

1. Clean the body threads of old sealing compound

using a wire brush.

Figure 3. Travel Setting

5

D Series

Loading...

Loading...