2. Apply new sealing compound (High-pressure,

high-temperature sealant) to the shoulder of the

seat ring (key 11). Let stand until tacky before

installing in pilot body (key 12).

3. Secure disk (key 21) to stem (key 19) with a stem

nut (key 22). Apply lapping compound to the disk

and insert this assembly into the pilot body (omit

the valve spring C).

4. Use a socket and extender to lap in the disk

(key 21) to seat joint. See Lapping Operations for

more information.

5. Screw pusher plate (key 8) onto the stem. Holding

the disk firmly against its seat, adjust the pusher

plate so that dimension C = 11/64 in. / 4.37 mm. A

gage (part number 05-02416-00) is supplied with

each repair kit. Be careful not to disturb the pusher

plate adjustment, use a prick punch to notch the

stem threads above the pusher plate so that the

pusher plate will not rotate freely. Work carefully

to avoid bending the stem. The valve travel is

now set.

6. Remove the stem nut and lift the stem assembly

(keys 19 and 8) out of the top of the pilot. Grind off

the stem Projection B flush with the upper surface

of the pusher plate. This can be done at the bench

without removing the stem from the body as long

as the grinder does not make contact with the

mating surfaces of the pilot body.

7. Reinsert the stem into the pilot body. Install disk

(key 21) and a stem nut (key 22).

8. Check that the valve travel A = 3/64 in. / 1.19 mm.

This need not be exact. Stem (key 19) should

move smoothly. Binding indicates a bent stem.

9. Remove the stem nut (key 22) and disk (key 21);

withdraw stem (key 19). Install stem with valve

spring (key 19), disk and both stem nuts.

Reassembly

1. If the seat ring (key 11), disk (key 21) and stem

(key 19) were not replaced, reinstall the seat ring

first, then slide the valve spring (key 9) over the

bushing (key 10) and slide the stem back into

place. If they were replaced, skip to step 3.

2. Install the seat ring (key 11) and stem nuts

(key 22) one at a time while holding the pusher

plate (key 8) with a socket.

3. Install the screen (key 20) and gasket (key 13).

Using the blind flange bolts (key 23), reinstall blind

flange (key 14).

Note

When replacing gaskets, be sure that

any serrated sealing surfaces are

cleaned of old gasket material.

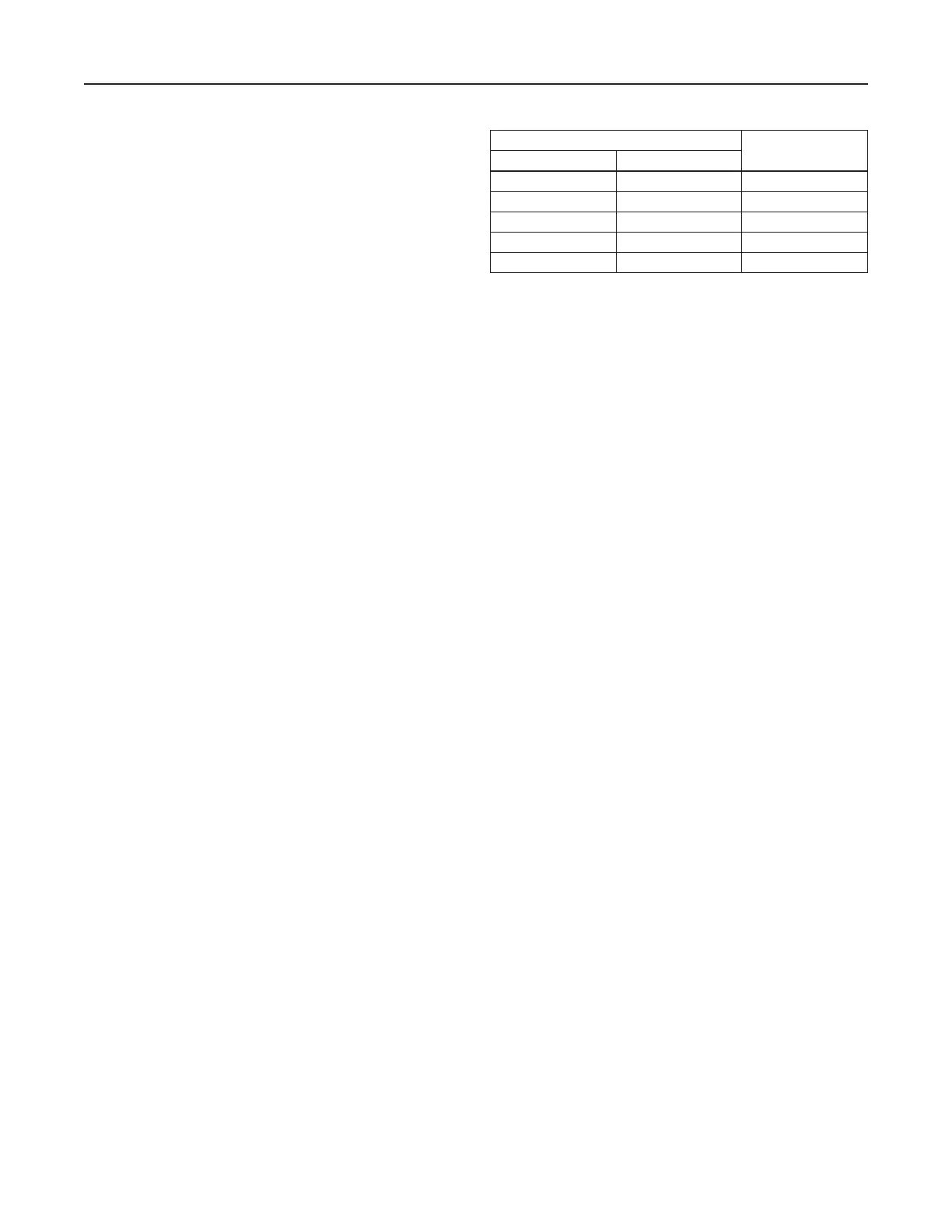

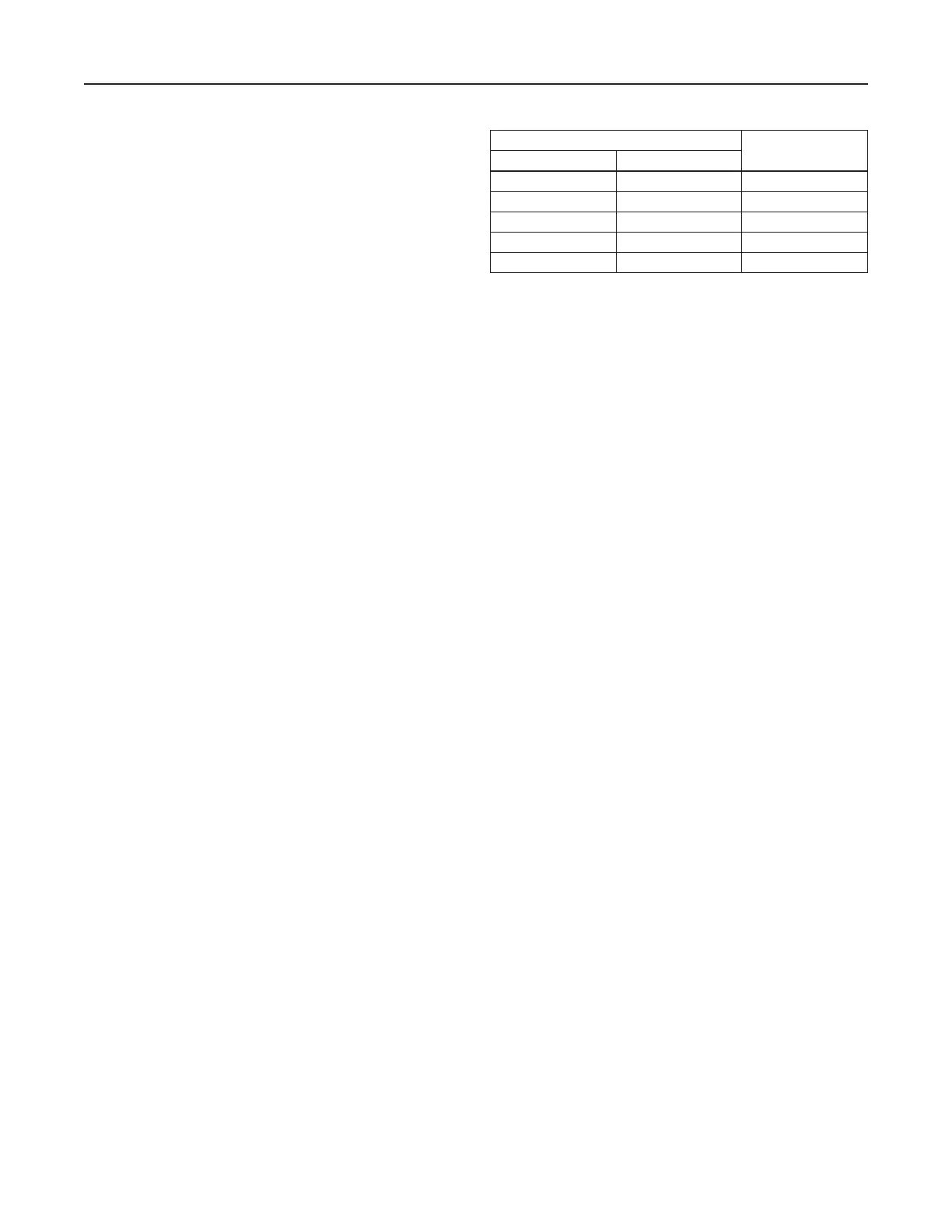

4. Assemble the diaphragm assembly (keys 7, 16

and 17) by sandwiching the diaphragms (key 17)

between the pressure plate (key 16) (flat side

against diaphragm) and the diaphragm screw

(key 7). The number of diaphragm disks depends

on the adjusting spring range. See Table 2.

5. Apply sealing compound (High-pressure, high-

temperature sealant) to the shoulder of the

diaphragm screw. Apply sealing compound to the

diaphragm flange of the pilot body for steel body

pilots only.

6. Put the diaphragm assembly into place (pressure

plate up). Center the assembly and install the

cowl (key 6). Install four diaphragm bolts or

studs (key 18) and diaphragm nuts (key 15)

equally around the cowl to ensure the diaphragm

assembly is centered. Install the rest of the

diaphragm nuts, bolts and/or studs and tighten in

an opposing pattern.

7. Install the spring button (key 5), adjusting spring

(key 4), spring yoke (key 2) and adjusting nuts

(key 1).

Parts Ordering

When ordering parts, it is essential that the pilot type,

service and serial number be stated.

Select part by item number, but order by part number.

Specify complete part number when ordering.

Parts List

Repair Parts Kit (See Table 3)

D Series and Options Parts List (See Tables 4 to 7)

ADJUSTING SPRING RANGE

DIAPHRAGM DISK

psig bar

0 to 8 0 to 0.55 1

3 to 20 0.21 to 1.38 2

5 to 50 0.35 to 3.45 2

10 to 100 0.69 to 6.89 2

20 to 150 1.38 to 10.3 3

Table 2. Number of Diaphragm Disk

6

D Series

Loading...

Loading...