Data di emissione: Settembre, 2016 Revisione: 1 Pag. : 37/44

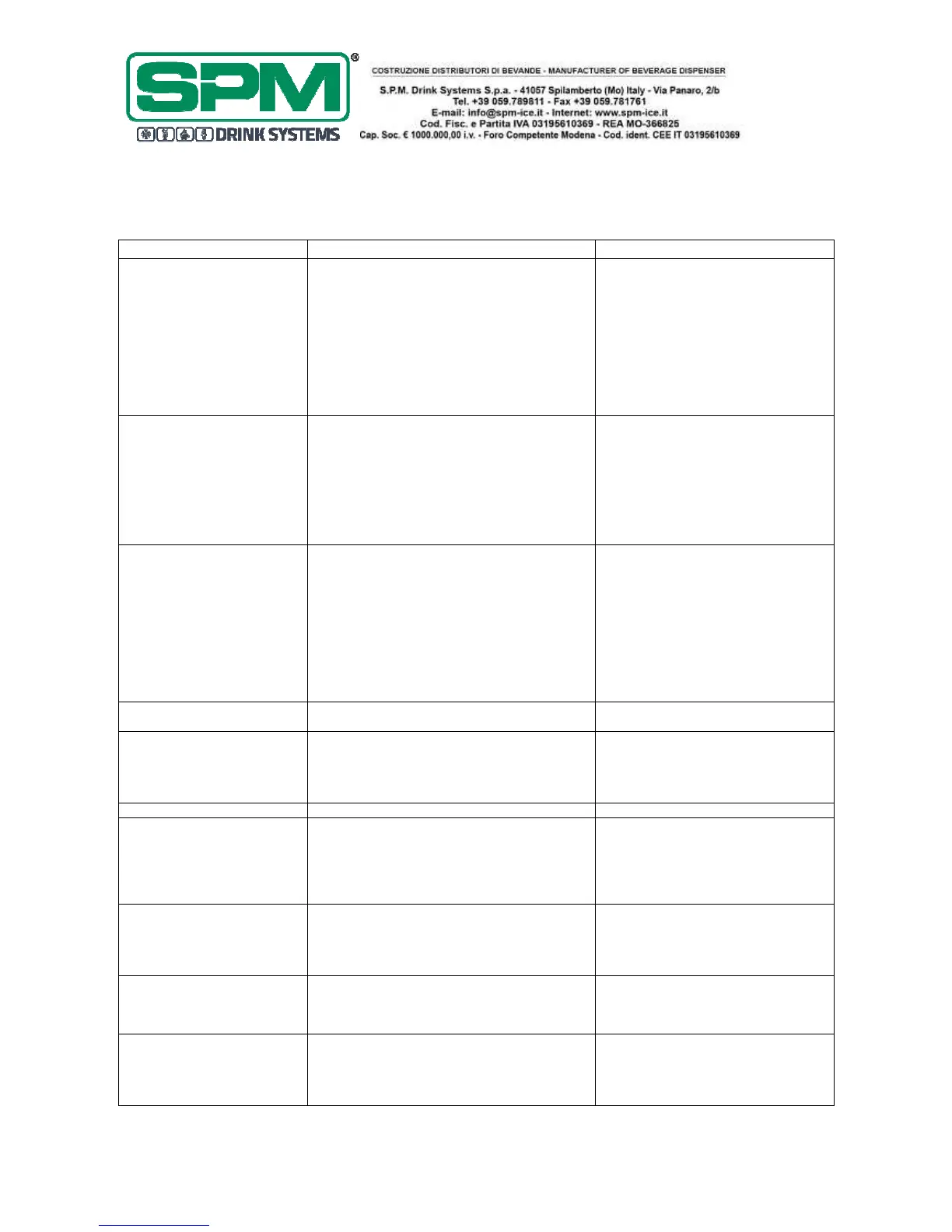

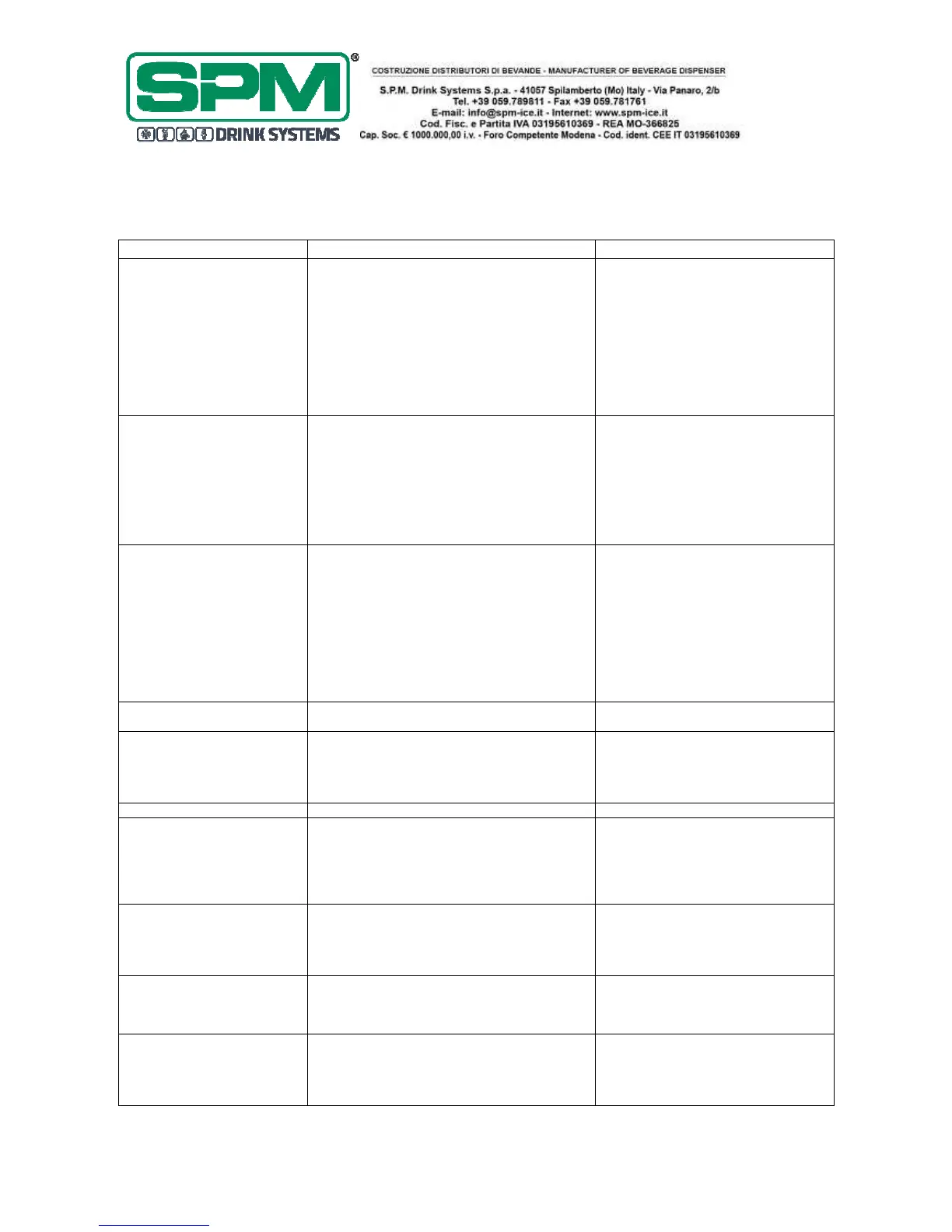

14. TROUBLESHOOTING GUIDE

NOTE: the following procedures must be performed by a qualified service technician.

Problem Possible cause Solution

The machine does not cool,

or cools only partially and

the compressor is running

• The inlet water flow is low

• The refrigeration system is working in

DEFROST mode

• The discharge pipe is partially obstructed

• Fan motor is not running

• Refrigerant is leaking

• Check the water flow and solve if

not enough

• Return to FREEZE mode

• Clean the discharge pipe and

solve the obstruction

• Check the fan motor’s electrical

connections and, if disconnected,

reconnect. If still not operating,

replace the motor

• Locate the leak, eliminate it and

recharge the system

The machine does not cool,

or cools only partially and

the compressor is not

running

• Electrical components of the compressor

are not functioning

• Some electrical connections are not

complete

• The compressor is malfunctioning

• No current is coming to the electronic

board

• Replace the malfunctioning

components

• Check the contacts and correct

those incomplete

• Replace the compressor

• Check the electrical connections

to the pc board as well as the

transformer feeding the PC

board and correct

The machine over-freeze,

making the auger movement

slow or stopped

• The product brix is too low

• The screw setting for the consistency

control system is set too far toward the

“+” position

• The limit micro-switch arm is bent away

from the gear motor and prevents

contact

• The level of the product in the bowl is

too low

• The compressor PC board contact don’t

open

• Check the product brix and

correct

• Reset the screw toward the “-“

position to produce a thinner

consistency product

• Using pliers, straighten the limit

switch arm

• Add more product or turn the

refrigeration “Off”

• Replace the PC board

The machine is noisy • The fan motor blades are hitting internal

components

• Check and correct

The main power switch is

“ON” but the unit s not

running

• The fuses are blown

• Some electrical connections are not

complete

• The control board is faulty

Replace the o-rings

Product is flowing into drip

tray through drainage pipe

• The bell shaped seal between the front of

the cylinder and the auger hub has not

been reinstalled properly

• The bell shaped shaft seal or the spindle

bushing seal is damaged or worn

• Find the seal and put it back in

place

• Replace the damaged/worn seal

and check the condition of the

drive shaft

The auger is not turning • Some electrical connections are not

complete

• The control board is faulty

Loading...

Loading...