13

from entering the dryer. The Blower M and Heater

H1 are de-energized when the temperature at the

bottom of the left tower, as sensed by the Left Tower

Temperature Sensor RTD1, reaches the Heat Ter-

mination set point. This indicates that the bed has

been fully heated.

The Repressurization Valve V11 is opened. A portion

of the dry air from the right tower now ows through

Repressurization Valve V11. This air is throttled to

near atmospheric pressure by Repressurization/

Sweep Orice O1. The dry, low pressure air ows

down through the left tower cooling the desiccant

bed, and exits through the Left Tower Purge Exhaust

Valve V3.

The Cooling Step continues until:

a) the left tower bed temperature falls to 150°F

or,

b) it is time to repressurize the left tower,

whichever occurs rst.

NOTE: In xed cycle, the bed will normally be par-

tially cooled because the repressurization step will

occur before the bed temperature can fall to 150°F.

NOTE: In Energy Management or Dew Point Con-

trol, as the drying time extends beyond 4 hours,

additional cooling time becomes available thus the

cooling step will frequently terminate based on tem-

perature providing complete bed cooling.

At the end of the Cooling Step, the Left Tower Purge

Exhaust Valve V3 is closed. The left tower slowly

repressurizes to full line pressure and is ready to go

back on-line.

NOTE: Bed cooling can be disabled by moving JP4

to the “ON” position.

6.3.1 Energy Management Control (optional)

Operation of the Energy Management Control cycle is

identical to the xed cycle except the cycle is extended

until the desiccant bed in the on-line tower has been fully

utilized. The off-line tower is regenerated and remains

in a stand-by mode after being repressurized.

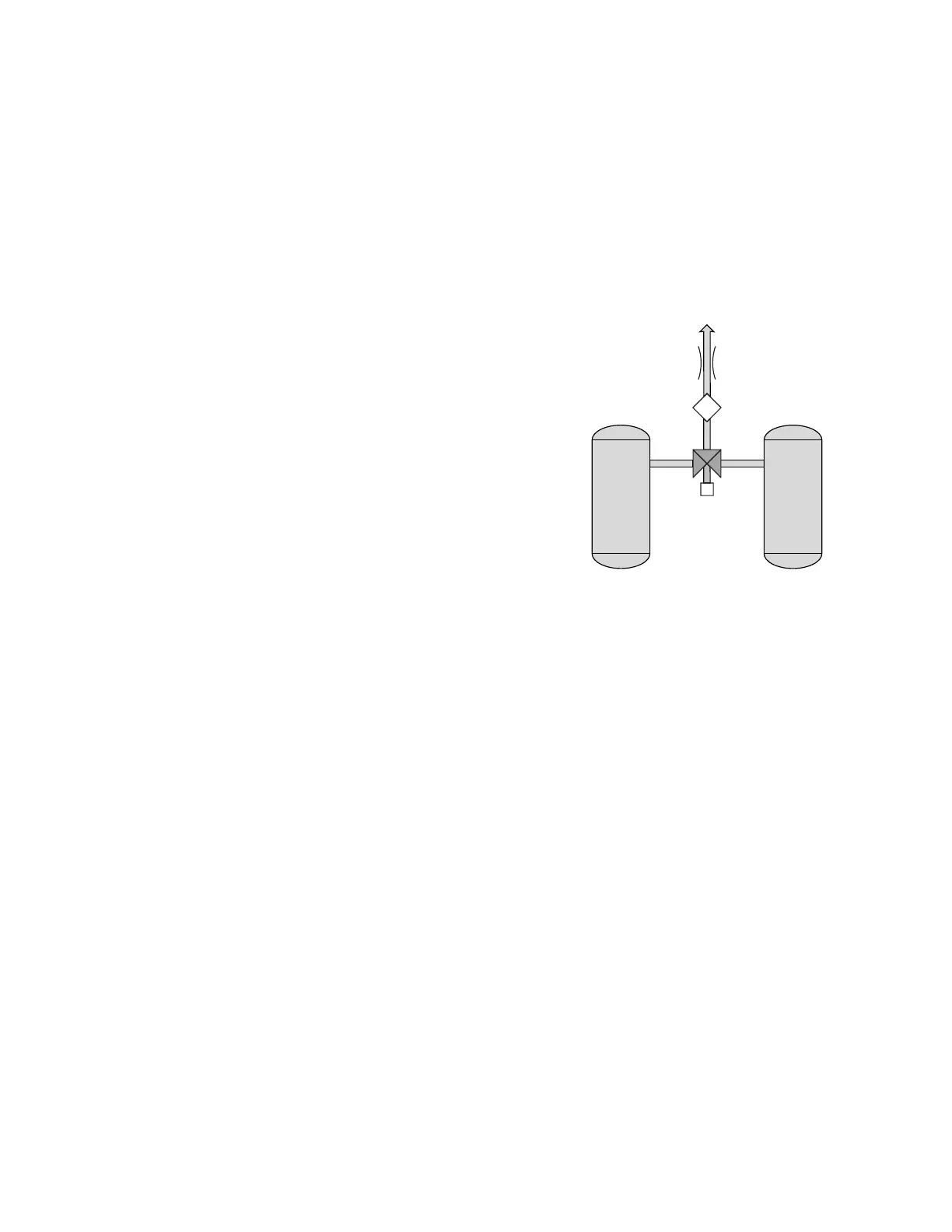

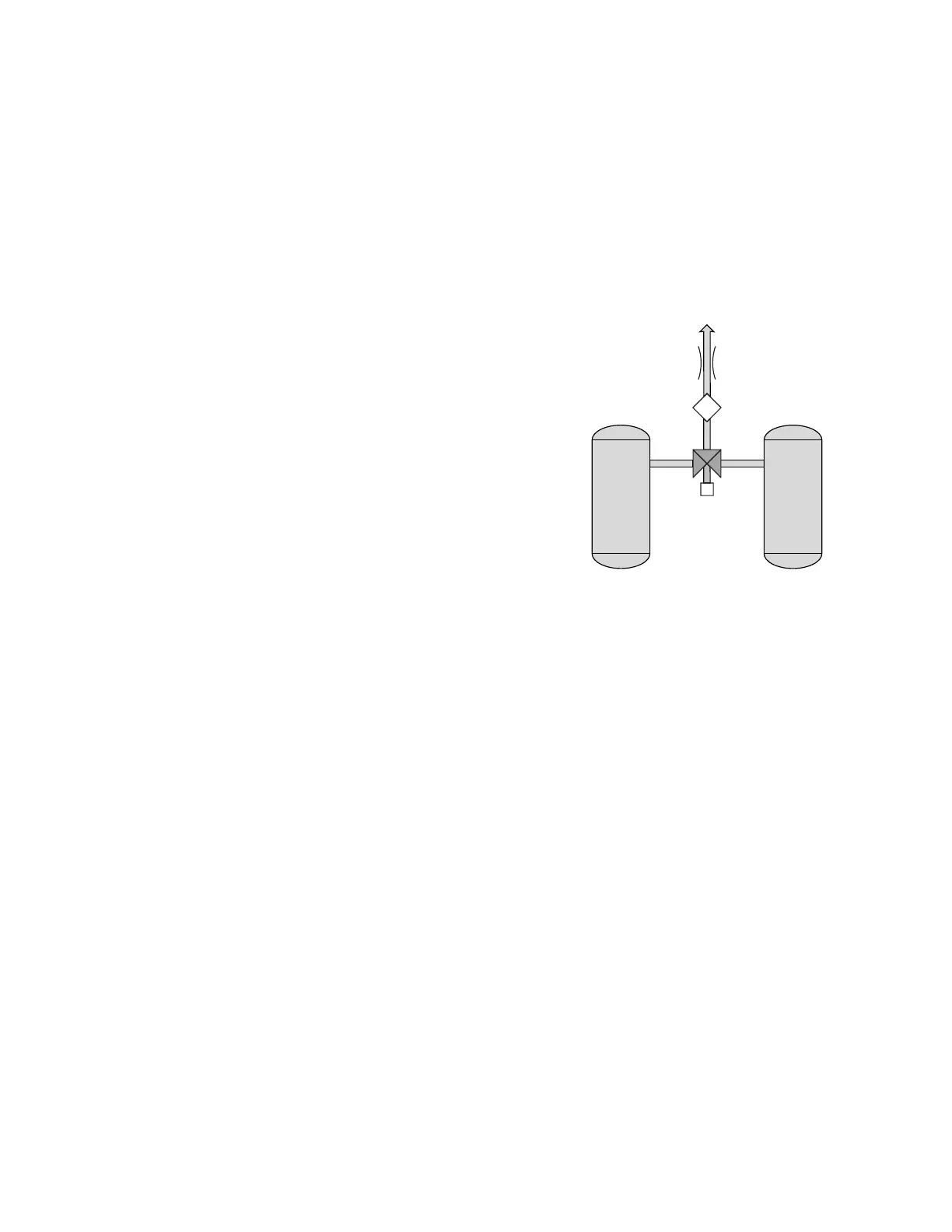

Figure 5 shows the air sampling system for the Energy

Management System – EMS option. A 3-way pilot valve

directs an air sample from the drying tower to the EMS

sensor. The EMS sensor detects the relative humidity

and temperature of the air sample. The air sample then

exhausts to atmosphere. The drying tower remains on-

line until the moisture front arrives at the sensor.

Figure 5

Optional Moisture Sensing

Energy Management System (EMS)

Loading...

Loading...