71

Technical Manual Gear Hub Systems 2010 · GEN.0000000002002 · Rev. A

SRAM

®

S7

ASSEMBLY

• Turn dust cap (7, Fig. 3) until the three

lugs (8) are between the three beads (9)

on the sprocket (10).

• Position dust cap and push towards

sprocket until it is felt to lock into place.

• Placing the wheel in the rear frame.

• Fit new retaining washer (3,5 mm thick)

on left axle end (1, Fig. 4).

The serrations must bear against the

dropout and the lug must engage in the

dropout slot.

• Fit the hoop guard (1, Fig. 5) on the right

axle side (drive side).

No additional washers or any acces-

sories are permitted.

Advice:

If a different protective bracket is used

the thickness of the attachment plate

must be max. 3 mm.

At least the beginning of the axle

thread must be visible in front of the

axle nut.

• Mount the axle nuts. Tightening torque

on axle nuts 30 – 40 Nm (266 – 350 in.lbs.)

• Version with coaster brake:

Mount the brake lever using a suitable

frame clamp (2, Fig. 4).

Caution:

Mount the brake lever between the two

straps of the frame clamp.

The clamp must be seated on the frame

without play.

Use a self-locking nut! Tightening

torque: 2 – 3 Nm (18 – 27 in.lbs.).

Caution:

Check that all the brake system

components are functioning properly!

ASSEMBLY SHIFTER

Advice:

• When choosing cable housing lengths,

be sure to allow enough housing for an

extreme turn of the handlebars in both

directions.

• Note also, that different stem lengths

and handlebar positions effects cable

housing length.

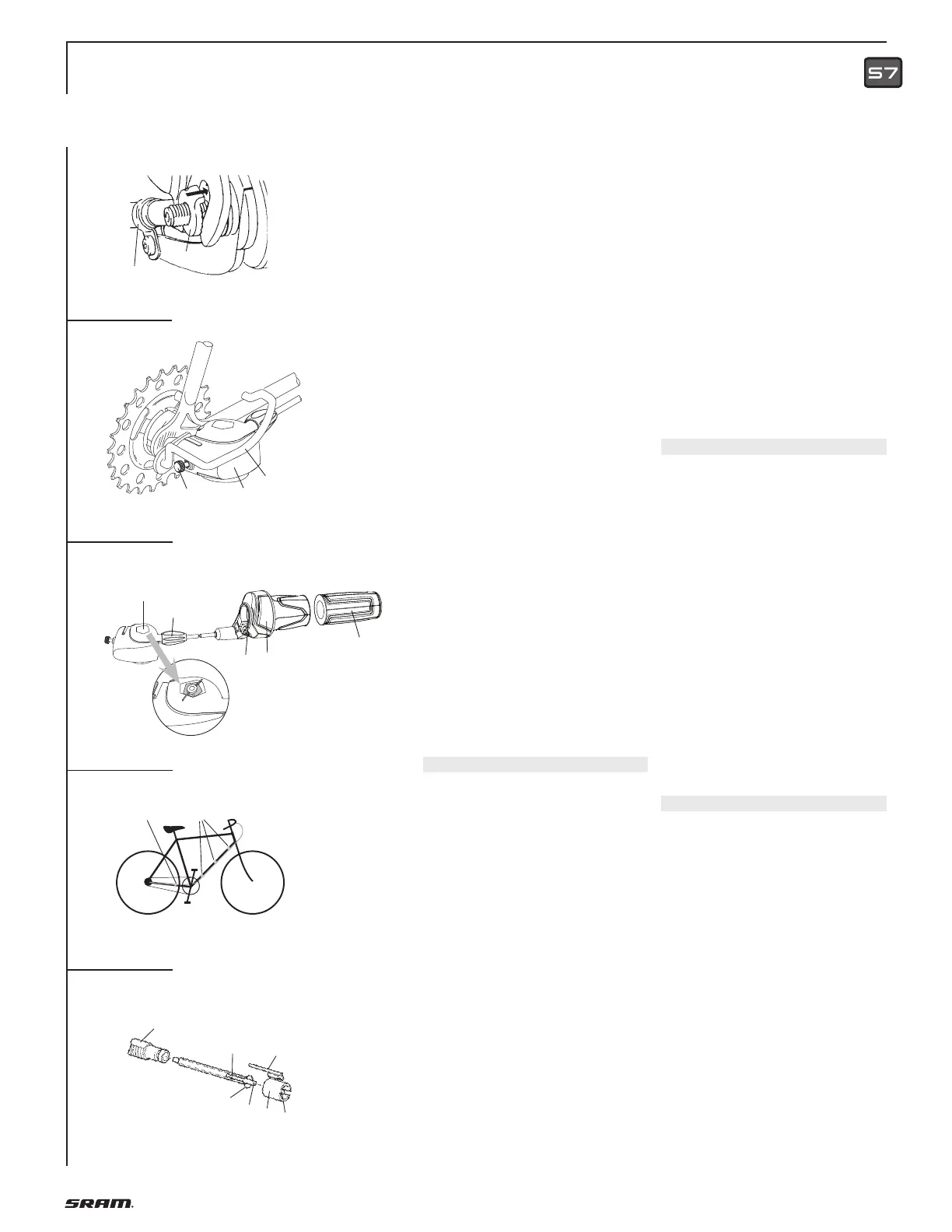

• Slide the shifter (1, Fig. 6) onto the

handlebar.

• Slide the handlebar grip (2) onto the

handlebar.

Caution:

Never use lubricants or solvents when

fitting handlebar grips. They have a

safety function and must not come free

from the handlebar.

• Place the shifter on the handlebar grip

and position so that you can use it com-

fortably. Tighten the clamping bolt (3). 3

mm Allen key, torque 3.5 – 4 Nm (31 – 35

in.lbs.).

Caution:

• Check that shifter and brake lever

can be easily operated (if necessary,

realign).

• Never ride without handlebar grips. The

turning grip of the twist shifter could

become loose. This can result in severe

injuries.

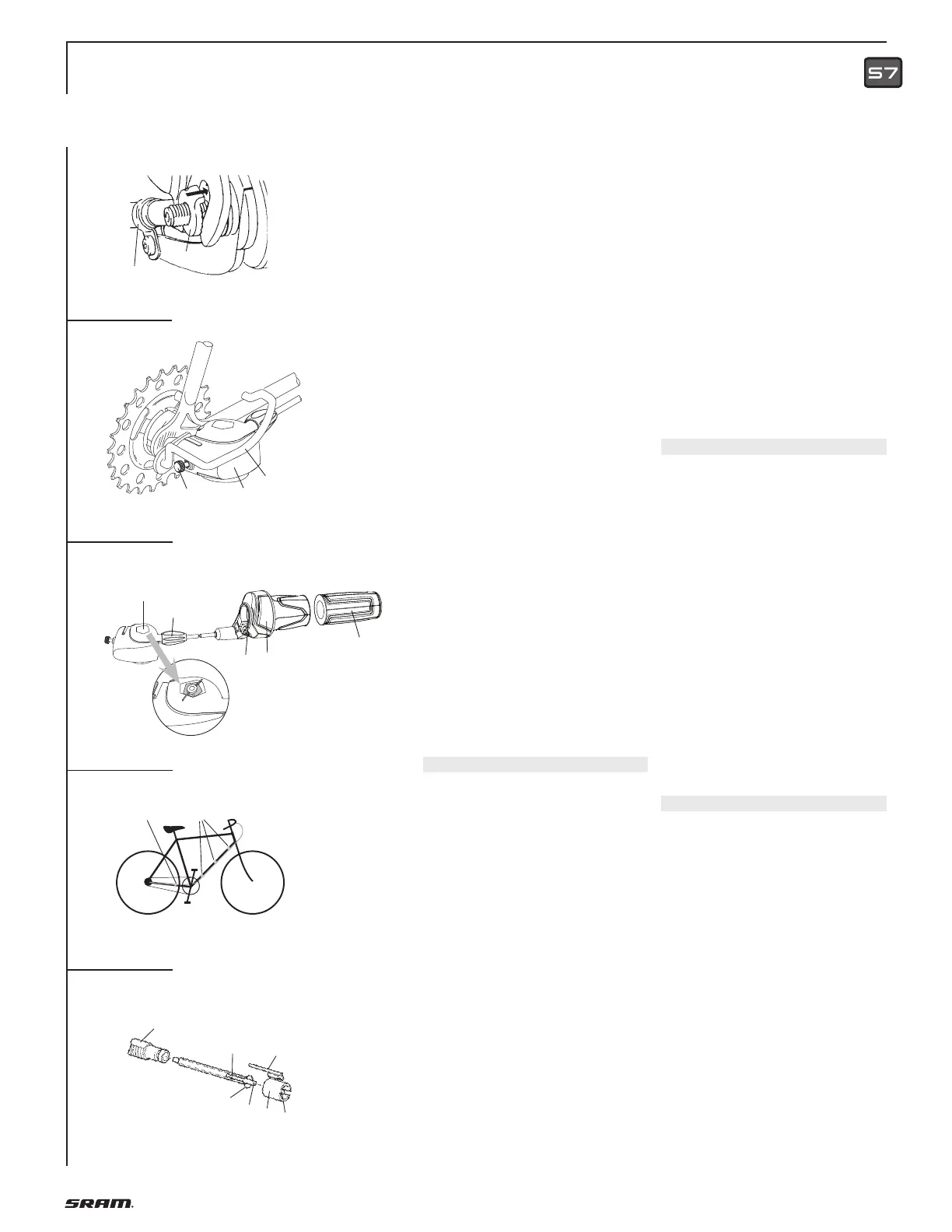

• When fitting the cable avoid small radi-

us. Attach the cable 3 times to the down

tube (1, Fig. 7).

• Last attachment point is on the lower

rear wheel fork (2, Fig. 7) immediately

behind the chain wheel.

Cable housing must be movable inside

attachment.

INSTALLING CLICKBOX

• Insert shift rod (1, Fig. 8) in shift tube (2)

(oil parts lightly) and then push into axle

bore as far as the stop. Turn slot (6) in

shift tube to a position where it is easily

visible.

• Push locating sleeve (3) with guiding rib

(4) to the front onto the hub axle – mak-

ing sure that the internal lug (5) is guid-

ed in the slot (6) of the shift tube until it

can be felt – and heard – to engage.

• Turn locating sleeve on the axle until

the guiding rib (4) is facing roughly

upwards.

• Place shifter in gear position “1“.

• Push on Clickbox (2, Fig. 5) to the stop

on the hub axle. The guiding rib (4, Fig.

8) of the locating sleeve thereby engag-

es in the slot on the housing. In the end

position tighten up the knurled bolt (3,

Fig. 5) by hand (0.3 Nm / 2.7 in.lbs.).

ADJUSTMENT

• Be sure to reset rotational shifter from

5th to 4th gear.

• Match up the marks in the Clickbox

viewing window (4, Fig. 6) by turning

the barrel adjuster (5).

Caution:

Check that all the brake system

components are functioning properly!

4

6

7

8

1

3

2

1

4

5

2

3

7

6

4

5

2

1

3

1

2

5

1

2

Loading...

Loading...