64

EN EN

65

START-UP

A. Unpacking

Unpack all items from the package and ensure that all items, specied within the

scope of the delivery are present.

B. Work environment

It is necessary to ensure well ventilation within the working area. The device is cooled

by the fan which ensures cooling for all internal subassemblies of the device.

(Tip! The guards must be installed in such way that the vent holes could be located

at the front side of the device) In order to leave some space for cleaning and cooling,

the device should be located within the distance of at least 15 cm (from each side)

from other objects. If the device is not efciently cooled, the make-time decreases.

C. Conduits connection

Each device is equipped with feeder cable which supplies it with electric voltage. If

the device is connected to the current source with the voltage exceeding supply

rated voltage or improper phase is connect, it may result in serious damage of the

machine. The device which has been damages in such course does not subject to

repair under the warranty terms.

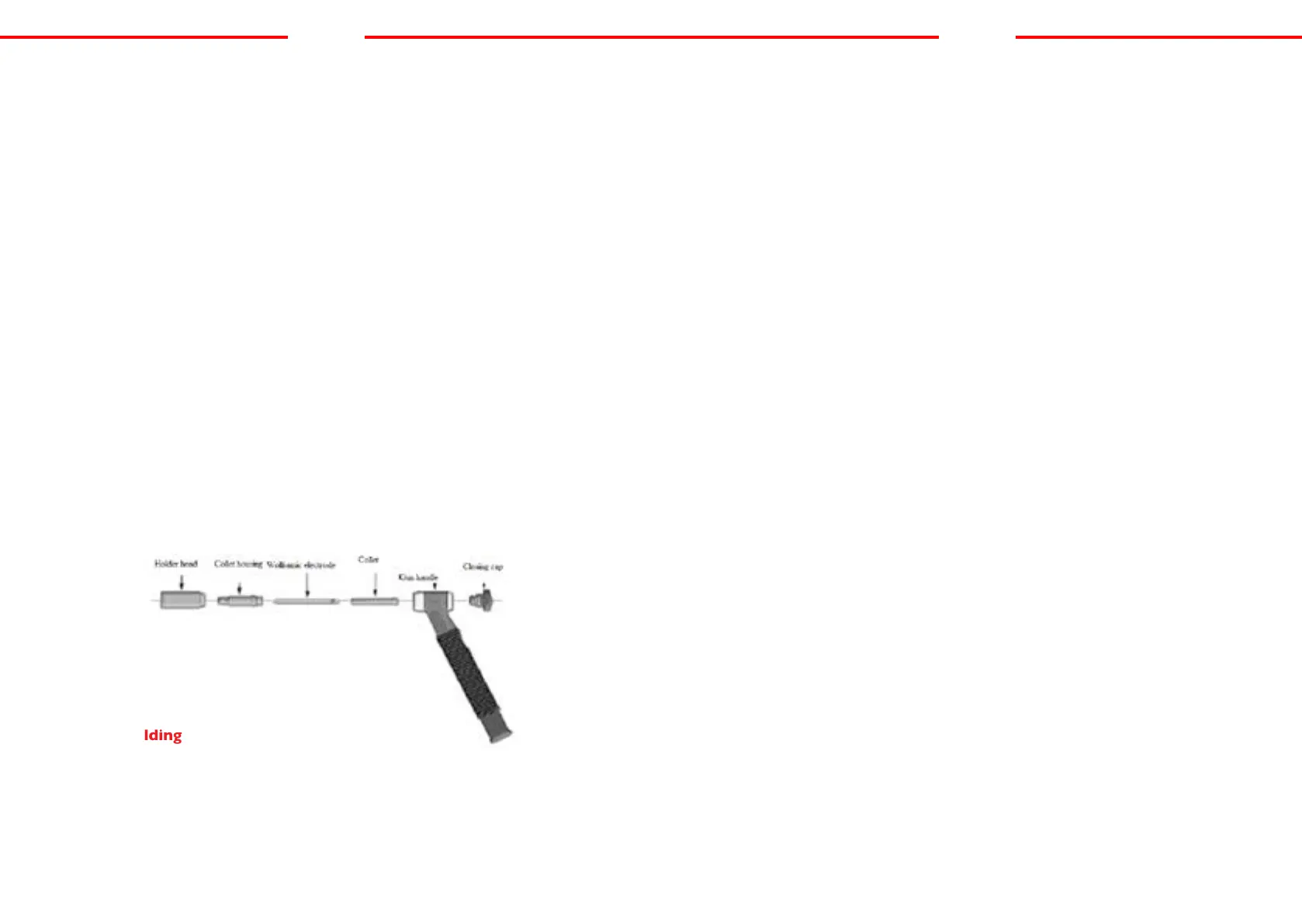

D. WIG-welding

The handle has to be take by the hand. Unto the black closing cap. Next, it is necessa-

ry to insert wolframic electrode into the collet. Next put the housing onto the collet

and tighten the holder head (Nozzle).

INSTRUCTION OF OPERATION

TIG-welding

Clearing the station before welding.

The TIG-welding is very sensitive about the surface (which is to be welded) contami-

nation. For this reason, before welding you have to remove rests of paints and greases

as well as the oxidized layer from the surface which will be welded.

DC TIG-welding

• Connect the gas hose to the gas to welder supply socket.

• Connect the gas hose to the welding gun and to the argon supply

(to the gun) socket.

• Connect weld piece to the mass clamp in welder, outlet (+).

• Connect the welding handle plug to the arc and argon control rod.

Gas test: Check the connection of the electric supply and switch on the volta-

ge. Open the valve (regulator) of bottle with argon and switch on ow meter. Gun

switch-key has to be pressed and you have to select an appropriate gas ow. The

inow switch-key has to be released and the gas inow will be automatically stopped

after several seconds. In case of using the high frequency ignition, the wolframic elec-

trode has to be retracted 2-3 mm from the weld piece. Next, after switching on the

switch-key, the arc will be triggered.

The switch off will result in the reduction of electric current intensity and the arc will

no longer be active. The blowing shaft can not decay before the electric arc switch off.

Gas must cool down the fusion weld as it will not become oxidized. After nishing

the welding process, you have to switch off the argon supply button on the bottle and

the welder supply. Pulling the electric supply plug when the electric supply switch is

on is prohibited.

Loading...

Loading...