44 45

Technical details

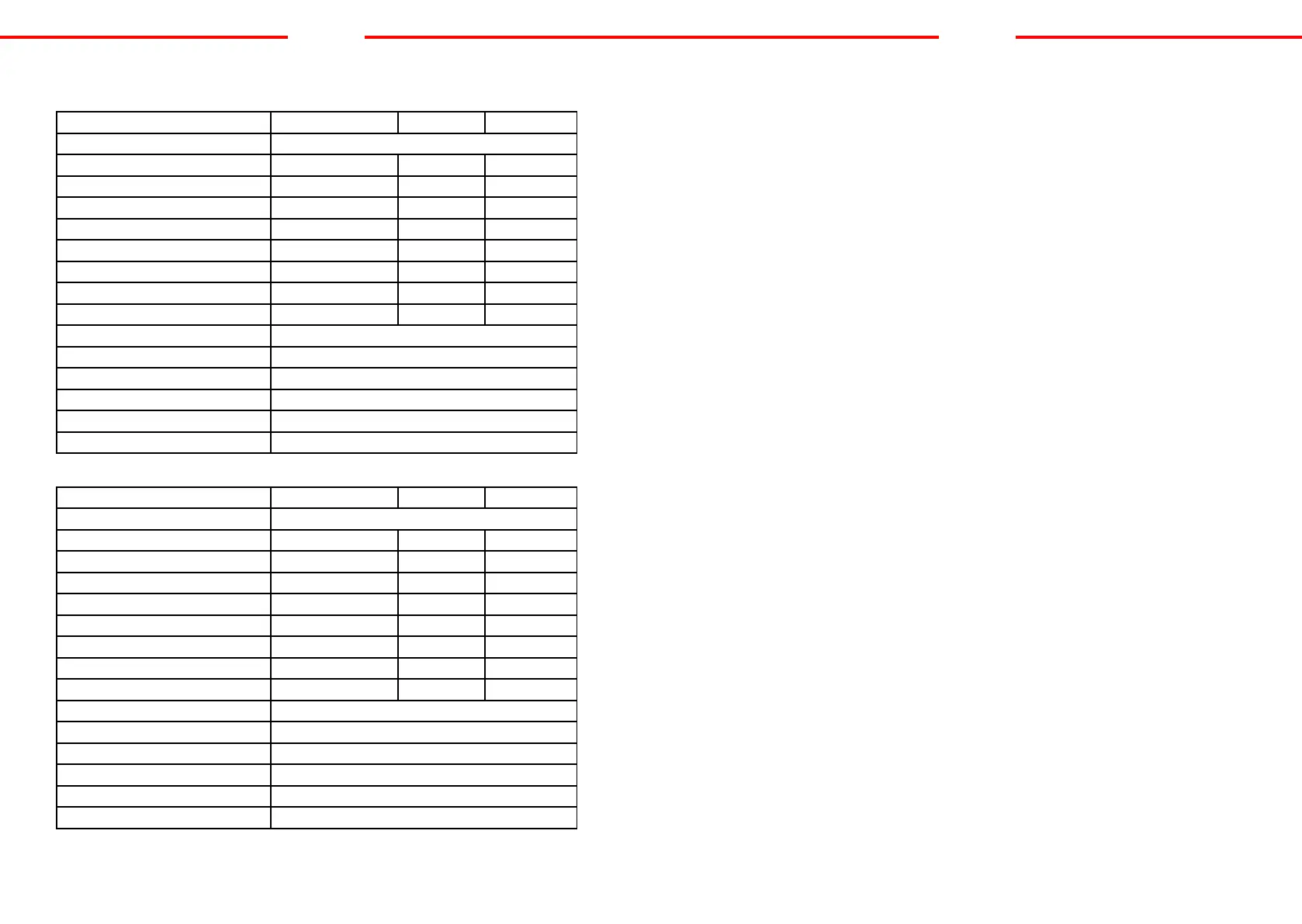

S-Multi 51 / 51P WIG MMA CUT

Network frequency (Hz) 50/60

Ignition HF: high frequency Contact Contact

Open circuit voltage (V) 62 62 250

Input current (A) 23,5 28 29

Welding current (A) 10 - 180 10 - 165 10 - 50

Compressor connection (Bar) - - 4,5

Gas ow (L/min.) 2 - 5 - 80 - 200

Electrode diameter max 1-3,2mm 1 - 4mm 1,2mm

Cutting capacity at max. 50 A - - 1 - 16mm

Model input voltage 230V, 1-Phase

Power factor (COSf) 0.93

Performance (%) 85

Weight (KG) 15

Dimensions (mm) 425x205x355

Protection class IP21

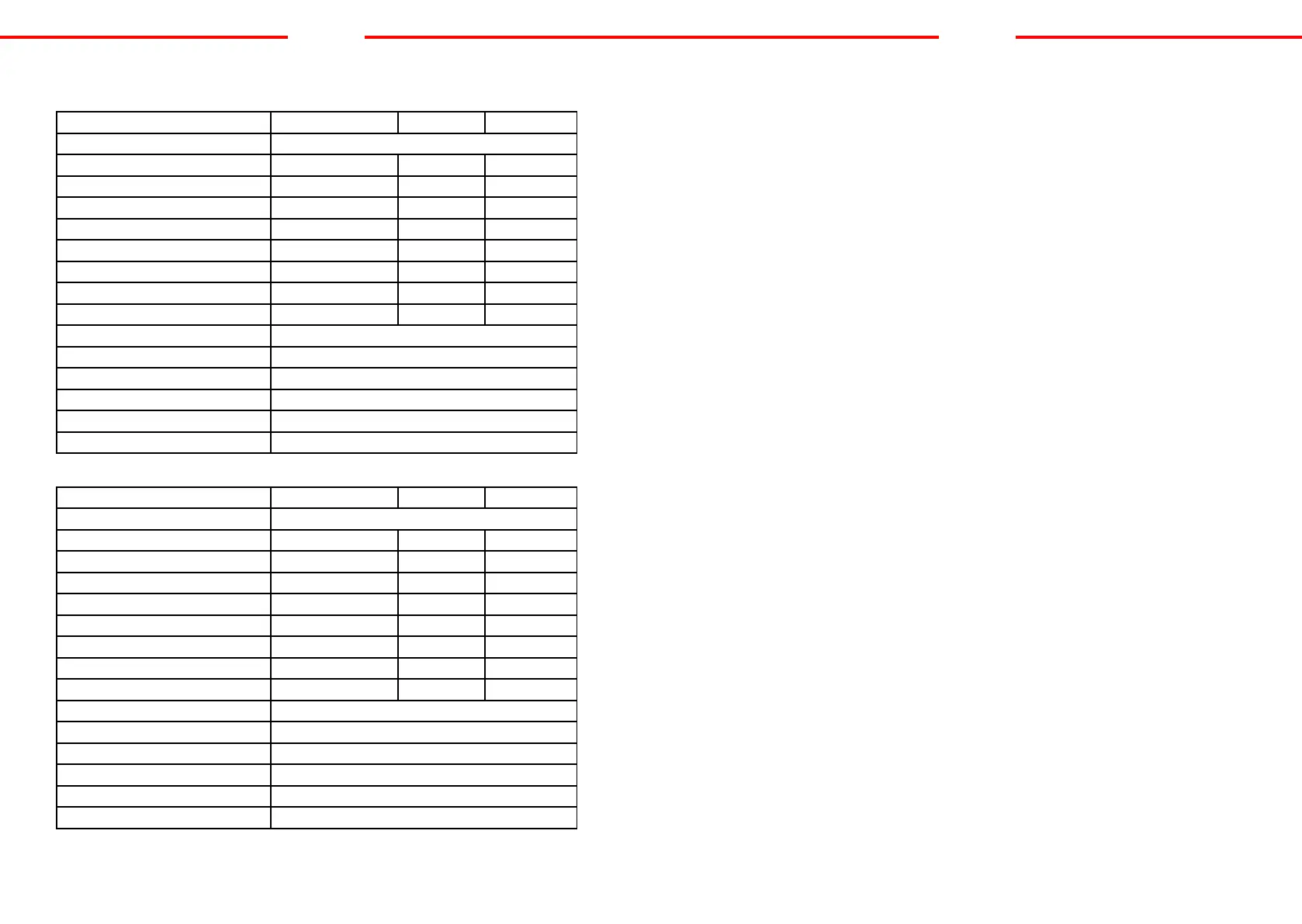

S-Multi 41 / 41P WIG MMA CUT

Network frequency (Hz) 50/60

Ignition HF: high frequency Contact Contact

Open circuit voltage (V) 52 52 230

Input current (A) 18 22 25

Welding current (A) 10 - 160 10 - 160 10 - 40

Compressor connection (Bar) - - 4,5

Gas ow (L/min.) 2 - 5 - 80 - 200

Electrode diameter max. 1-3,2mm 1 - 4mm 1,2mm

Cutting capacity at max. 40 A - - 1 - 12mm

Model input voltage 230V, 1-Phase

Power factor (COSf) 0.93

Performance (%) 85

Weight (KG) 13

Dimensions (mm) 425x205x355

Protection class IP21

EN

INITIATING OPERATION

A. Unpacking

Unpack all the items out of the box and make sure that you have received all items

listed on the packing list.

B. Work environment

Make sure that the work area is well ventilated. The unit is cooled by an axial fan that

provides an air ow for the electronics through the rear panel.

(Note! The panel must be installed in a way where the vent holes are located closer to

the front of the device.)

Leave at least approx.15 cm at the front and 15 cm on each side for cleaning.

If the machine is operated without adequate cooling, the length of the duty cycle will

be reduced greatly.

C. Cable connections

Each unit is equipped with a main power cable, which is responsible for providing cur-

rent and voltage to the device. If the device is connected to power which exceeds the

required voltage, or if the wrong phase is set, it may lead to severe damage to the unit.

This is not covered by the warranty for the equipment and the user will be responsible

for such situations.

D. Torch connection

Connect the torch to the inverter by connecting the air tube that is attached at the

end of the torch to the torch connector on the front part of the machine. Ensure that

the connection is secure by tightening it slightly with a spanner. However you should

not make it too tight.

EN

Loading...

Loading...