16

G

B

by a 16 A fuse. Before you use the machine,

make sure that the mains voltage complies with

thespecificationsontheratingplate.Longsupply

cables,extensions,cablereelsetc.causeadropin

voltageandcanimpedemotorstart-up.Inthecase

oflowtemperaturesbelow+5°C,motorstart-upis

jeopardizedasaresultofstiffness.

5.4 On/Off switch (ref. 8)

5.4.1 D 200/8/24 - D 200/10/24 (Fig. 2a)

Toswitch on the equipment set the On/Offswitch

(ref.8)topositionI.

Move the On/Off switch (ref. 8) to position O to

switchofftheequipment.

5.4.2 D 200/8/6 (Fig. 2b)

Toswitchonthecompressor,pullouttheredknob

(ref.8)to position I.

To switch off the compressor, press the red knob

(ref.8)inagainto position O.

5.5 Adjusting the pressure

● You can adjust the pressure on the pressure

gauge(ref.6)usingthepressureregulator(ref.

7).

● Thesetpressurecanbetakenfromthequicklock

coupling(ref.5).

5.6 Setting the pressure switch

Thepressureswitchissetatthefactory.

5.6.1 D 200/8/6 - D 200/8/24

Switch-onpressure6bar

Switch-offpressure8bar

5.6.2 D 200/10/24

Switch-onpressure8bar

Switch-offpressure10bar

6. CLEANING AND MAINTENANCE

Warning!

Pull the power plug before doing any cleaning

and maintenance work on the appliance.

Warning!

Wait until the compressor has completely cooled

down. Risk of burns!

Warning!

Always depressurize the tank before carrying

out any cleaning and maintenance work.

6.1 Cleaning

● Keep the safety devices free of dirt and dust

as far as possible. Wipe the equipment with a

clean cloth or blow it with compressed air at low

pressure.

● We recommend that you clean the appliance

immediatelyafteryouuseit.

● Cleantheapplianceregularlywithadampcloth

andsomesoftsoap.Donotusecleaningagents

or solvents; these may be aggressive to the

plastic parts in the appliance. Ensure that no

watercangetintotheinterioroftheappliance.

● Youmustdisconnectthehoseandanyspraying

toolsfromthecompressorbefore cleaning. Do

not clean the compressor with water, solvents or

thelike.

6.2 Condensation water

Thecondensationwatermustbedrainedoffeach

daybyopeningthedrainvalve(ref.11)(onthefloor

ofthepressurevessel).

Warning!

The condensation water from the pressure

vessel will contain residual oil. Dispose of the

condensation water in an environmentally

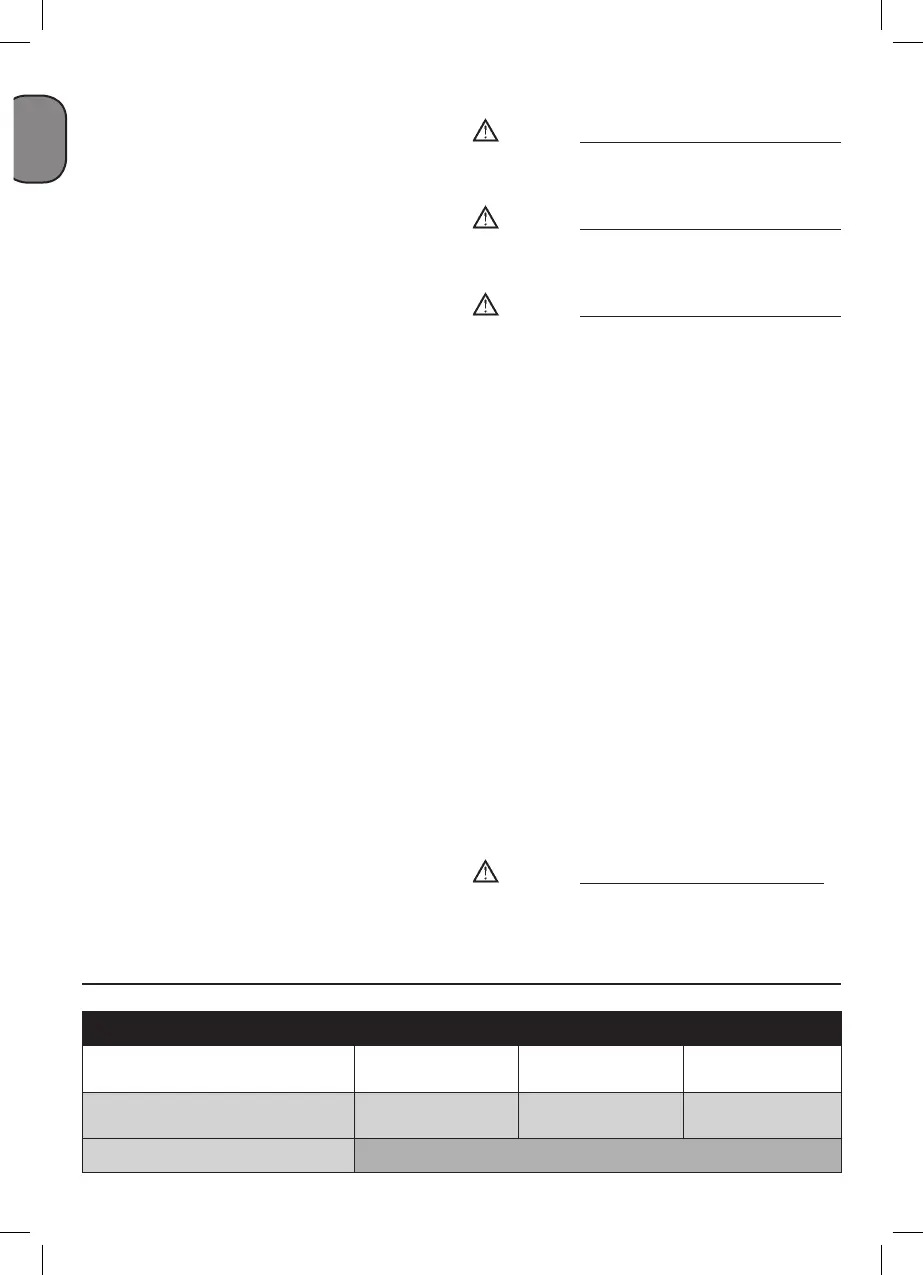

MAINTENANCE RESUMPTIVE TABLE

FUNCTION

AFTER THE FIRST

100 HOURS

EVERY 100 HOURS

Cleaning of intake filter and/or

substitution of filtering element

● ●

Draining tank condensate Periodically and at the end of work

Loading...

Loading...