7. Maintenance

BEFORE ANY INTERVENTION ALWAYS DISCONNECT

THE ELECTRICAL SUPPLY!

Periodically check that all screws are tightly fastened and the

condition of the various guards

V BELTS

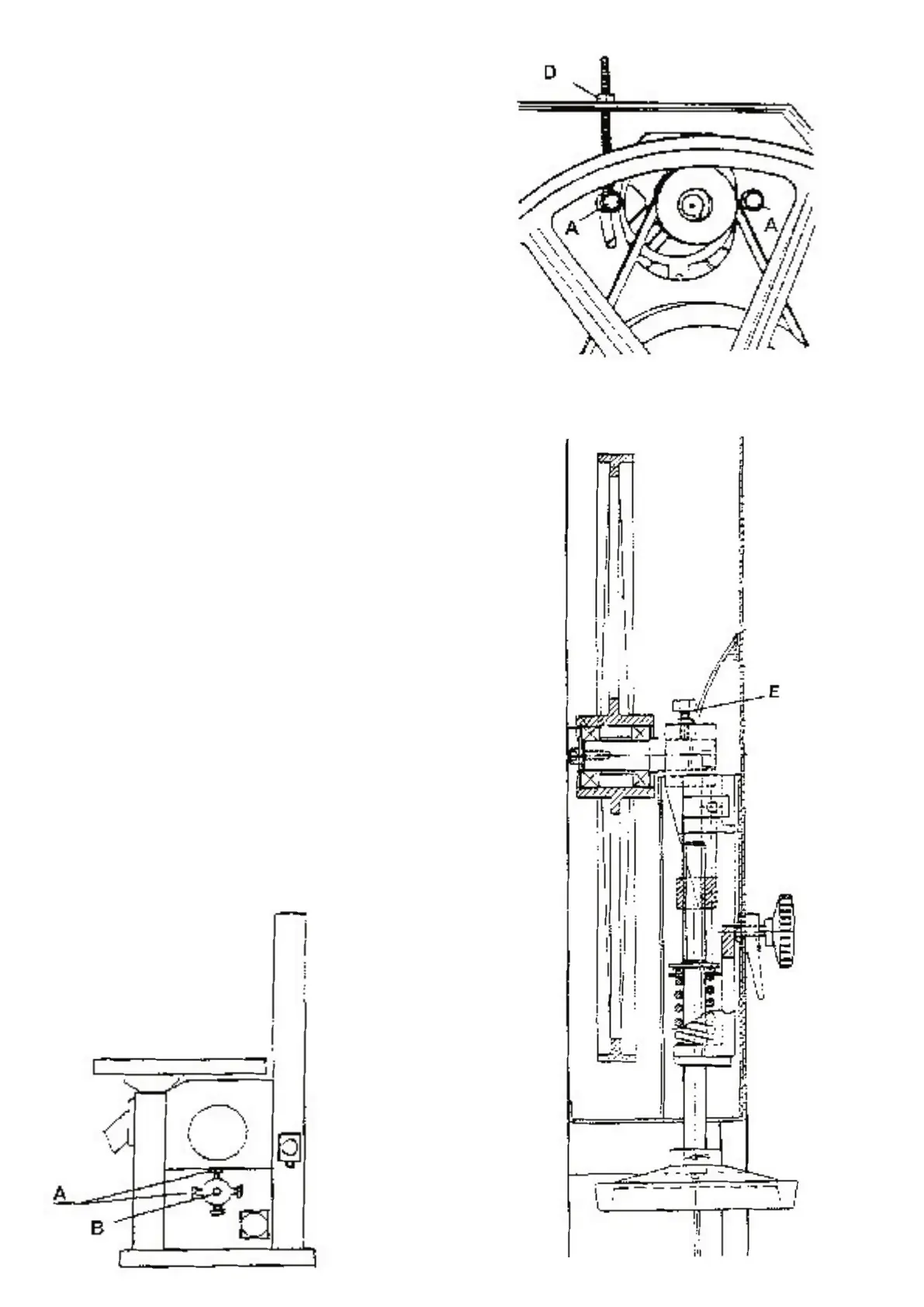

After the first few hours of operation it is necessary to check

that the tension of the belts is correct,as they tend to stretch.

To control the tension of the belts push the mid-point of the

belt applying 3-4 Kg of pressure, the displacement should not

exceed 5-6 mm. To adjust the blade tension loosen the nuts A,

FIG. 23, and tighten the nut

D, FIG. 23, this will increase the

tension, tighten the nuts .

It is recommended that the correct blade tension is maintained

as loose belts reduce the motor power and can increase the

braking time. Belts that are too tight can cause the belts to

become hot .

TO CHANGE THE BELTS

Slacken the tension as described above, remove the screw “

B”,

FIG. 22, loosen the screws “

A”,

pull-out the bandwheel and shaft, repeat the operations in

reverse to re-assemble.

IMPORTANT: loosen only the 2 screws indicated so as not to

interfere with the alignment of the fly-wheel.

DISMANTLING THE UPPER FLY-WHEEL

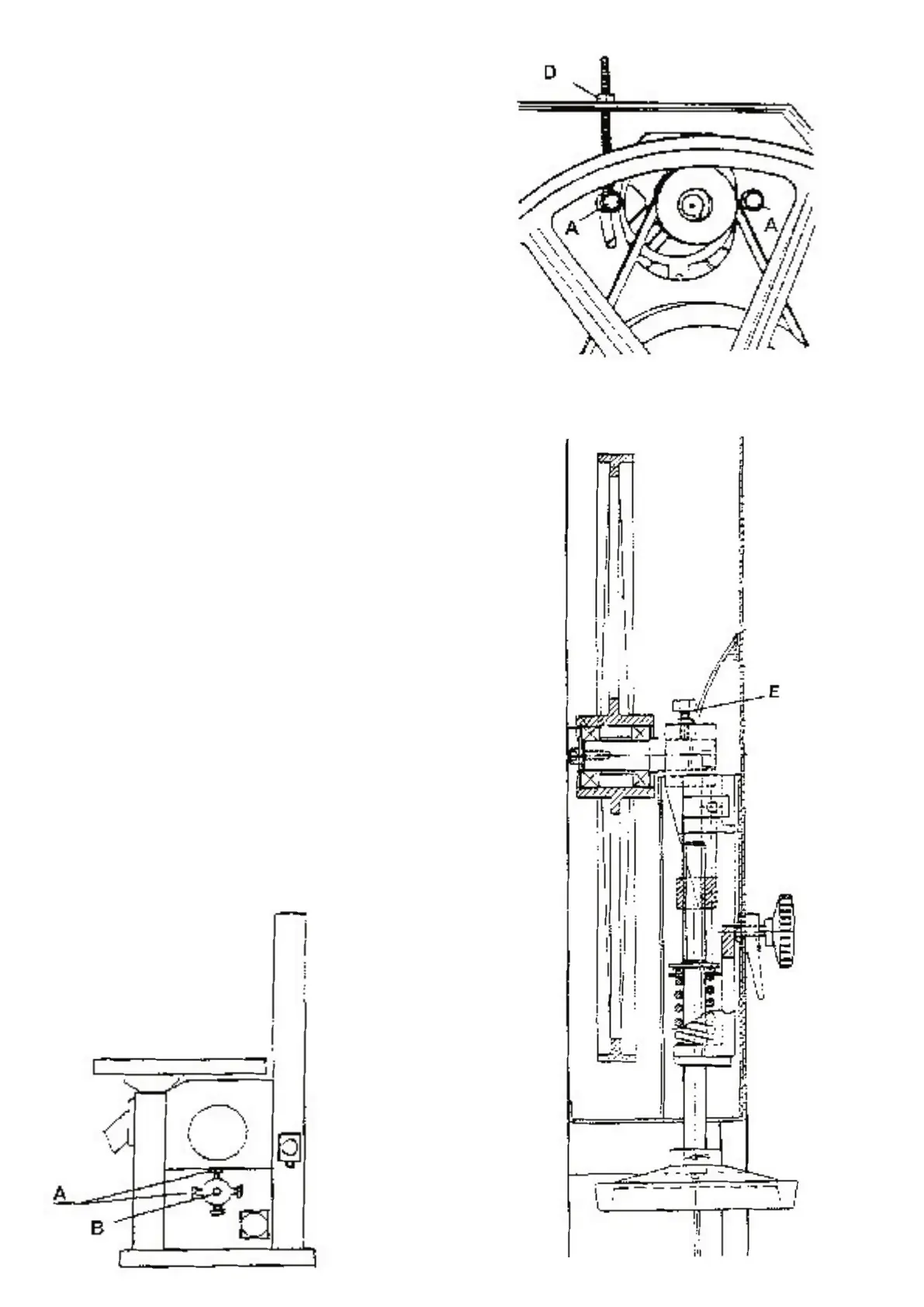

Remove the screw “

E”,FIG.24 and remove fly-wheel and shaft

from their positions.

REPLACEMENT OF RUBBER COVERING OF

THE FLY-WHEELS

It is recommended that this be carried out by a competent

specialist or the manufacturer, this is because the rubber

covering is not only glued onto the fly-wheel, but also ground in

a crown form. It is strongly advised not to grind and shape the

rubber directly on the machine using gouges, files or abrasives.

CLEANING AND LUBRICATING

Periodically clean the inside of the machine with the aid of a

dust extractor for any saw-dust deposits, remove any resinous

deposits from the fly-wheels surface. The fly-wheel bearings

do not require any greasing. It is not necessary to lubricate any

part or component of the machine as the sawdust circulating

within will adhere to any oiled or greased surface jeopardizing

the sliding of moving parts such as the shaft of the blade guide

adjustment and the slide of the tensioning group.

Frequently control the cleanliness of the rubber surfaces on the

fly-wheels, particularly in cases of cutting resinous materials or

chip-board. Clean the surfaces, while machine is not in motion ,

of any resinous deposits taking care do not damage the surface.

FIG. 22

FIG. 24

FIG. 23

Loading...

Loading...