Solutions Strategies and Innovations

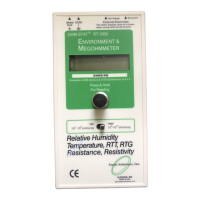

Static Solutions Inc. - Ohm - Stat RT - 1000 Information

ANSI/ESD-S20.20-1999

most sensitive level of the items to be handled in

accordance with the Program shall be documented.

The Organization shall establish, document,

implement, maintain and verify the compliance of

the Program in accordance with the requirements of

this document.

6.0.2. ESD Control Program Guidance

The primary objective of a Program is to provide

continuous ESD protection. Electrostatic control and

protection entails implementation of Program

requirements during design, production, inspection,

test, storage, shipment, installation, use,

maintenance, replacement and repair functions.

6.0.3. Tailoring

This document, or portions thereof, may not apply to

all applications. Tailoring is accomplished by

evaluating the applicability of each requirement for

the specific application. Upon completion of the

evaluation, requirements may be added, modified or

deleted. Tailoring decisions, including rationale,

shall be documented in the ESD Control Program

Plan (hereafter referred to as the “Plan”).

6.1 ESD CONTROL PROGRAM ADMINISTRATIVE

REQUIREMENTS

6.1.1 ESD Control Program Plan

6.1.1.1. ESD Control Program Plan Requirement

The Organization shall prepare an ESD Control

Program Plan that addresses each of the

requirements of the Program. Those requirements

are: The Plan, Training, Compliance Verification and

ESD Control Program Plan Technical Requirements.

The Plan is the principal document for implementing

and verifying the Program. The goal is a fully

implemented and integrated Program that conforms

to internal quality system requirements. The Plan

shall address the requirements as described herein

and shall apply to all applicable facets of the

Organization’s work. The Plan shall contain the

specific requirements for the organization and be

evolutionary as technologies, processes or

procedures change. If there is a contractual

requirement for device or assembly testing, options

for determining ESD Sensitivity include QPL-19500,

QML-38535, VZAP data or manufacturer’s data

sheets. Efforts to identify and eliminate defects, and

prevent their introduction, shall be a component of

the Plan to reduce the cost and risk associated with

ESD damage.

6.1.1.2. ESD Control Program Plan Guidance

The Plan should describe the scope of the Program;

describe the tasks, activities, and procedures

necessary to protect ESD sensitive items at or

above a specified sensitivity level; identify

organizational responsibilities for the tasks and

activities; and list directive or supportive documents

used in the Program. The Plan should include a

listing of the specific type of ESD protective

materials and equipment used in the Program. A

major element in an effective Plan is the assessment

of the ESD susceptibility of parts, assemblies and

equipment and their required protection levels. A

common method for establishing ESD sensitivity

limits is to use one or more of the three ESD models

used for characterization of electronic items. These

are HBM, MM, and CDM (see Appendix A). The

selection of specific ESD control procedures or

materials is at the option of the Plan preparer and

should be based on risk assessment and the

established electrostatic discharge sensitivities of

parts, assemblies, and equipment. The Plan should

ensure that the Organization and suppliers of ESD

sensitive items have established and implemented a

Program in accordance with this document.

6.1.2. Training Plan

6.1.2.1 Training Plan Requirement

Initial and recurrent ESD awareness and prevention

training shall be provided to all personnel who

handle or otherwise come into contact with any

ESDS items. The type and frequency of ESD

training for personnel shall be defined in the Training

Plan. The Training Plan shall document the

procedures for recording this training in personnel

training records. Training methods and the use of

specific techniques are of the Organization’s option.

The option that is selected shall include an objective

evaluation technique to ensure trainee

comprehension and training adequacy.

6.1.2.2. Training Plan Guidance

Recurrent ESD training for personnel is an integral

part of the Program. ESD training includes initial

and recurrent training required to reinforce program

requirements and modifications based upon

lessons-learned. New technologies and correction

of deficiencies identified during reviews and audits

should also be part of the training process. The

training requirements should be developed in

conjunction with the Organization’s handling

procedures for ESDS parts, assemblies and

equipment.

6.1.3. Compliance Verification Plan

6.1.3.1 Compliance Verification Plan Requirement

A Compliance Verification Plan shall be established

to ensure the organization’s compliance with the

requirements of the Plan. Formal audits or

certifications shall be conducted in accordance with

Loading...

Loading...