ENGLISH ENGLISH

22 23

22 23

Left rotation: Turn the selector switch for drilling/hammer

drilling 5 on both sides to the stop in the position.

Set the direction of rotation for hammer drilling, drilling

and chiselling always to right rotation.

Switching On and O

push the lock-on button 6.

release it.

Setting the Speed/Impact Rate

The speed/impact rate of the switched on power tool can

switch 7/10 is pressed.

increases the speed/impact rate.

Safety Clutch

If the tool insert becomes caught or jammed, the

drive to the drill spindle is interrupted. Because of the

forces that occur, always hold the power tool rmly

with both hands and provide for a secure stance.

If the power tool jams, switch the machine o and

loosen the tool insert. When switching the machine

on with the drilling tool jammed, high reaction torques

can occur.

4.2 Working Advice

Changing the Chiselling Position

In this manner, the optimum working position can be set

for each application.

Insert the chisel into the tool holder.

Turn the mode selector switch 8

Turn the tool holder to the desired chiselling position.

Turn the mode selector switch 8 to the “chiseling” position.

The tool holder is now locked.

Switching On/O: A

it depressed.

Switching On/O: B

top ( I ) until it locks.

the bottom (O) and release it.

hammer/impact capacity only after a certain time.

Setting the Speed/Impact Rate

The electronic control 10 enables stepless speed and

impact preselection in accordance with the material to be

worked.

The maximum hammering capacity is achieved when the

thumbwheel 10 is set to position “6”.

due to technical reasons.

Setting the Impact Rate HD3C K

You can set the impact rate of the switched on power tool

continuously, depending on how far you press down the

causes a low impact rate. Stronger pressure increases

the impact rate.

OPERATION MD15K - MD15BK

4.3 Starting Operation

Observe correct mains voltage! The voltage of

the power source must agree with the voltage

specied on the nameplate of the machine.

Power tools marked with 230V can also be

operated with 220V.

Switching On and O

position.

the “O” position.

rate only after a certain time.

This start-up time can be shortened by striking the chisel

4.4 Operating Instructions

While working, hold the power tool with both hands by the

handle 1.

moderate pressure.

5. Maintenance and Service

5.1 Maintenance and Cleaning

Before any work on the machine itself, pull the mains

plug.

For safe and proper working, always keep the machine

and ventilation slots clean.

A damaged dust protection cap should be changed

immediately. We recommend having this carried out

by an after-sales service.

Clean the tool holder 2 each time after using.

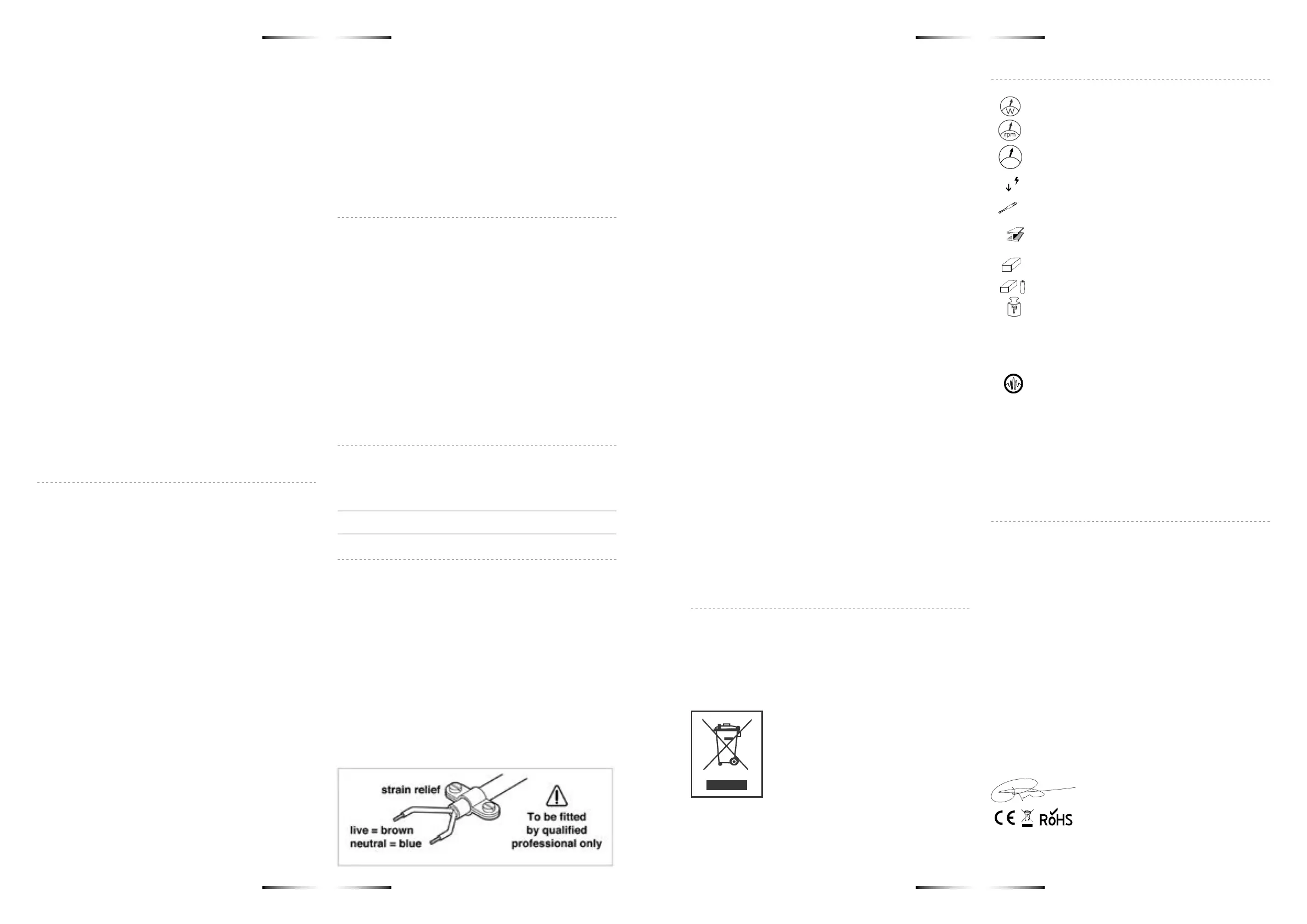

WARNING! Important instructions for

connecting a new 3-pin plug to the 2-wire

cable.

The wires in the cable are coloured according to the

following code:

Do not connect the blue or brown wire to the earth terminal

of the plug.

Important: If for any reason the moulded plug is removed

from the cable of this power tool, it must be disposed of

safely.

When the carbon brushes wear below acceptable

service tolerances, the machine will automatically cut

out. The machine must be sent to customer service for

maintenance for address, see the “Service and Customer

Assistance” section.

Sharpening Chisels

Good results are only achieved with sharp chisels;

therefore, sharpen the chiselling tools in good time. This

ensures a long service life of the tools and good working

performance.

Re-sharpening

Sharpen chiselling tools using grinding wheels (e.g.ceramic

bonded corundum wheel) with a steady supply of water.

no annealing coloration appears on the cutting edges; this

forging, heat the chisel to between 850ºC and 1050°C

(bright red to yellow).

hardening, heat the chisel to approx. 900 °C and

quench in oil. Then anneal in an oven for approx. one hour

at 320°C (annealing colour = light blue).

If the machine should fail despite the care taken in

manufacturing and testing procedures, repair should be

carried out by an after-sales service centre for Stayer

power tools.

In all correspondence and spare parts order, please

always include the article number given on the type plate

of the machine.

5.2 Disposal

We recommend subjecting electric tools, accessories and

packaging to a recovery process that respect the

environment.

Do not throw away electric tools!

In accordance with European Directive

2012/19/UE on unserviceable electric and

electronic apparatus, after transposition

into national law, electric tools must be

collected separately to subject them to

ecologic recycling.

Subject to change without notice.

5.3 Technicaldata

= Power input.

= Load speed.

= Percussion.

= Percusive energy.

= Insertion.

= Maximum drilling, steel.

= Maximum drilling, stone.

= Maximum drilling, with core bit.

= Weight.

L

pA

= Sound pressure level.

L

WA

= Sound power level.

= Vibration.

The values given are valid for nominal voltages [U]

can vary. Please observe the article number on the type

plate of your machine. The trade names of the individual

machines may vary.

5.4 Declaration of conformity

The undersigned: STAYER IBERICA, S.A.

With address at:

Calle Sierra de Cazorla, 7

Área Empresarial Andalucía - Sector 1

28320 PINTO (MADRID)

Tel.: +34 91 691 86 30

We declare under our own responsibility that the product

as describe und “Technical data” is in conformity with the

following standards or standardized documents:

EN 60745-1, EN 60745-2-6, EN 55014-1, EN 55014-2,

EN 61000-3-2, EN 61000-3-3 in accordance with the

provisions in Directives 2000/14/EC, 2006/42/EC,

2011/65/EU, 2014/30/EU.

Director General

January, 2021

ipm

e

STEEL

STONE

STONE

Loading...

Loading...