Four programs are factory-set for

the most common types of work.

Press button “P” for programming

mode. Number 1 is displayed for

program 1. Continuing to press

the program button will take you

to programs 2 – 4. Pressing the

button again will return the tool to

normal operation.

Features - Getting started

The tool is switched ON and OFF

at the multi-stage switch on the

back of the grip handle. The dis-

tance from the object you are

working on depends on material

and intended method of working.

Always try out the air flow and

temperature on a test piece first.

Using the attachable accessory

nozzles (see accessories page on

the cover) the flow of hot air can

be controlled with maximum pre-

cision. Take care when changing

hot nozzles! When using the hot

air gun in the self-resting position,

make sure it is standing on a

stable, non-slip and clean surface.

Default programs

The settings for the four programs

can be changed and saved at any

time. To do this, press the first pro-

gram button “P” until the display

shows the program you wish to

change. Set the chosen air flow

and temperature. Now press the

memory button (10) “

–

>” until the

“

–

>” symbol is cleared from the

display (approx. 5 sec). The values

entered are now saved in the

program memory. To return to

normal operation, press the

program button until the program

symbol disappears from the

display.

Operation

Stage 1 is the cold-air stage; tem-

perature is always 50 °C. Use the

cold-air function for drying paint,

cooling workpieces or to cool the

nozzle before changing an acces-

sory attachment.

In stage 2 temperature can be

infinitely varied over a range of

50 °C to 650 °C on the crontol

panel with LCD display. The actual

temperature is measured at the

nozzle outlet and indicated on the

display. The red push button (9)

on the left-hand side is used as

an input button with minus/plus

function. Temperature settings

range from 50 °C to 650 °C max.

Briefly pressing the “+” / “–”

push button increases or reduces

the temperature setting in 10 °

steps. Pressing the button for

longer speeds up the temperature

setting process. Once the tempera-

ture has been set, the tool takes a

few seconds to reach temperature

(depending on speed/air flow). If

you want to alter the setting, simply

press either button to increase or

reduce the temperature. After

switching OFF, the hot air gun

stays in the last setting.

Setting the temperature

The grey button panel (7) on the

right below the display is used for

regulating air flow and blower

speed. Air flow can be controlled

in several stages using the “+/–”

function and can be varied from a

minimum of 150 l/min to a max-

imum of 500 l/min. Use the cold-

air function for drying paint, cool-

ing workpieces or to cool the

nozzle before changing an acces-

sory attachment.

Setting air flow

Programming [P]

Memory function [S]

- 9 -- 8 -

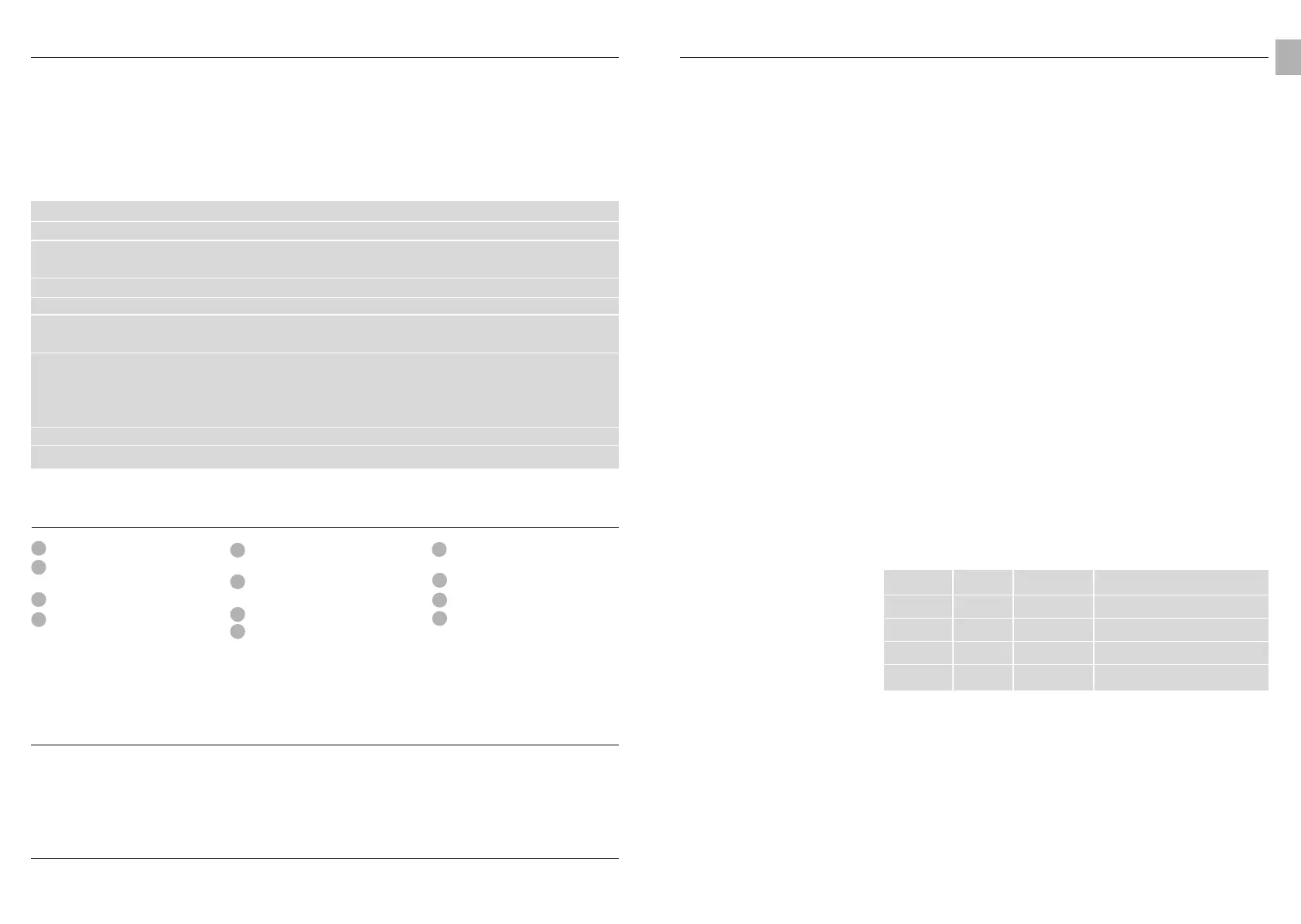

Program Temp. °C Air l/min Application

1 250 approx. 350 Forming plastic pipes

2 350 approx. 400 Welding plastic pipes

3 450 approx. 500 Stripping paint

4 550 approx. 400 Soft soldering

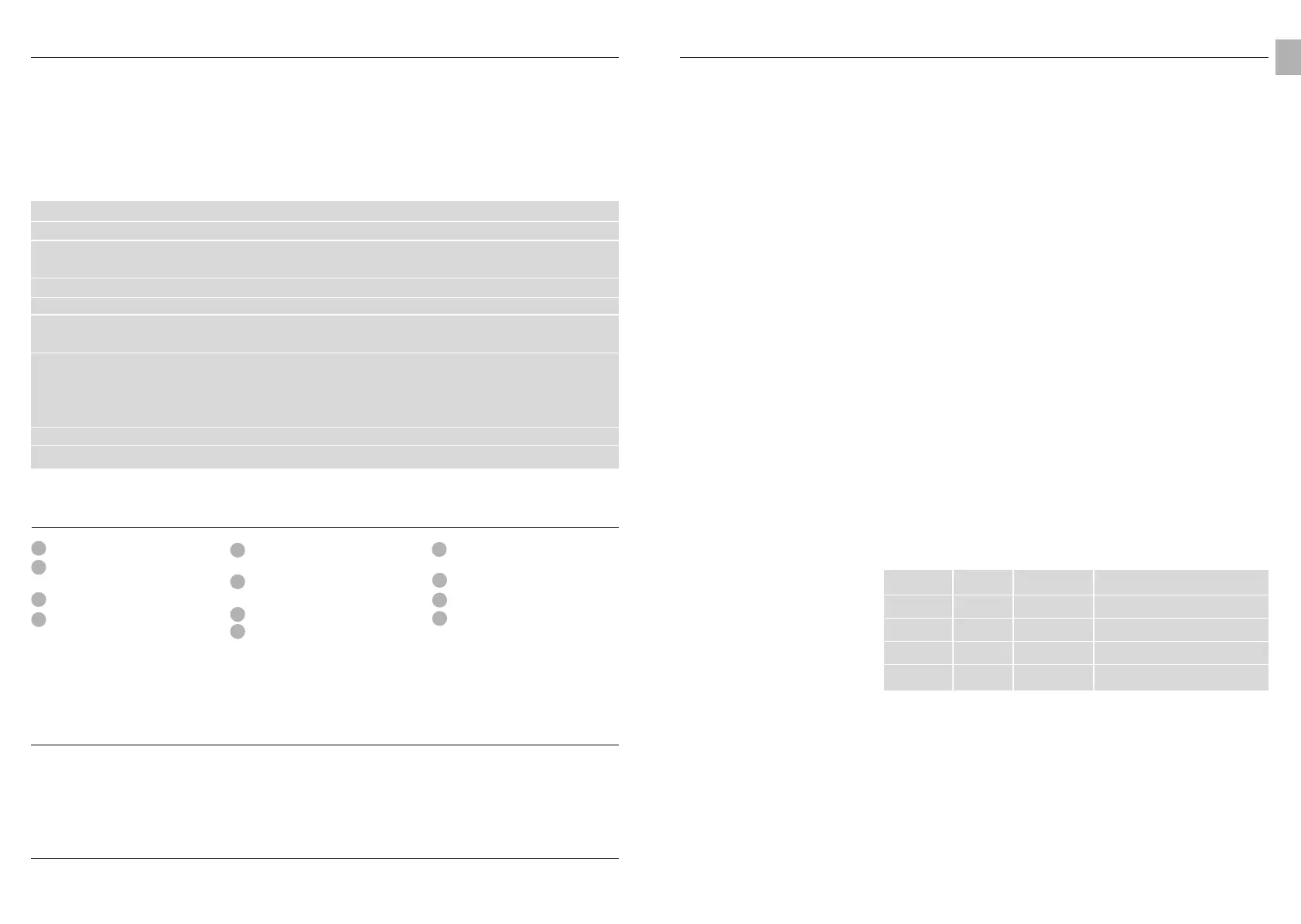

Mains voltage

Output

Temperatures

Display

Blower

Air flow

Programs

Memory button

Enclosure

230 – 240 V, 50 Hz

2300 W

Stage 1: 50 °C,

Stage 2: 50 – 650 °C

LCD in 10 °C steps

Continuously variable

Stage 1: 150 – 250 l/min

Stage 2: 150 – 500 l/min

1 = 250 °C / approx. 350 l/min

2 = 350 °C / approx. 400 l/min

3 = 450 °C / approx. 500 l/min

4 = 550 °C / approx. 400 l/min

for changing the program settings

II (without earth terminal)

Technical specifications

CE Declaration of Conformity

This product conforms to Low-voltage Directive 73/23/EEC and EMC Directive 89/336/EEC.

Stainless steel outlet

Air intake with lattice guard

to keep out debree

Detachable guard sleeve

Stand for stable, non-slip

stationary work

Heavy-duty rubber-sheathed

cord

ON/OFF switch/multi-stage

switch

Push button for setting air flow

Temperature and speed display

on LCD

Push button for setting

temperature

Memory button

Program selector button

Soft grip handle for comfortable

operation

Tool elements

1

2

3

4

5

6

7

8

9

11

12

10

for deciding to choose a STEINEL

hot air gun. This tool can be used

for completing a wide range of

jobs safely and reliably, such as

soldering, welding PVC, shaping,

drying, shrink-fitting, stripping

paint etc. All STEINEL tools are

manufactured to the highest

standards and undergo a strict

process of quality control.

Used in the proper manner

(please read the information on

p. 10), this hot air gun will give

you lasting satisfaction.

Thank you

For your safety

The tool is double protected from overheating:

1. A temperature sensor switches OFF the heating element in the event of improper tool use;

the blower continues to run.

2. The thermal cut-out completely shuts down the tool if it is overloaded.

GB

Titel+Inhalt_Profi_24spr 01.07.2004 14:19 Uhr Seite 9

Loading...

Loading...