4

CAUTION: A unit cannot be used as an integral part of a machine superstructure

which would impose additional loads on the unit other than those imposed

by the torque being transmitted either through a shaft-mounted

arrangement, and any shaft mounted power transmitting device. (e.g.

sprockets, pulleys, couplings)

CAUTION: For safe operation and to maintain the unit warranty, when changing a

factory installed fastener for any reason, it becomes the responsibility of

the person making the change to properly account for fastener grade,

thread engagement, load, tightening torque and the means of torque

retention.`

LUBRICATION

CAUTION: On ALL quill style input units with a motor mounted vertical shaft up or

quill under on the input will require a double input seal arrangement to

prevent leakage or C-face coupled style units should be used. Consult

factory.

All standard helical ratio multipliers ordered from the factory are shipped with standard

compounded lubricant and is good for ambient temperature ranges of 30 F to 104 F. All

washdown and stainless steel helical ratio multipliers ordered from the factory are shipped with

synthetic NSF H1 Food Grade lubricant and are good for ambient temperature ranges of -10 F

to 105 F. Double reduction units have separate oil sumps and must be filled and checked

independently. Use of synthetics can cause problems if they are not compatible with the seals

or conventional lubes they replace. Prior to startup, verify that the oil is at the level shown

on the drawing below. If the ambient temperature will be outside the range for the lubricant

installed at the factory, drain and refill the reducer with the proper viscosity lubricant prior to use.

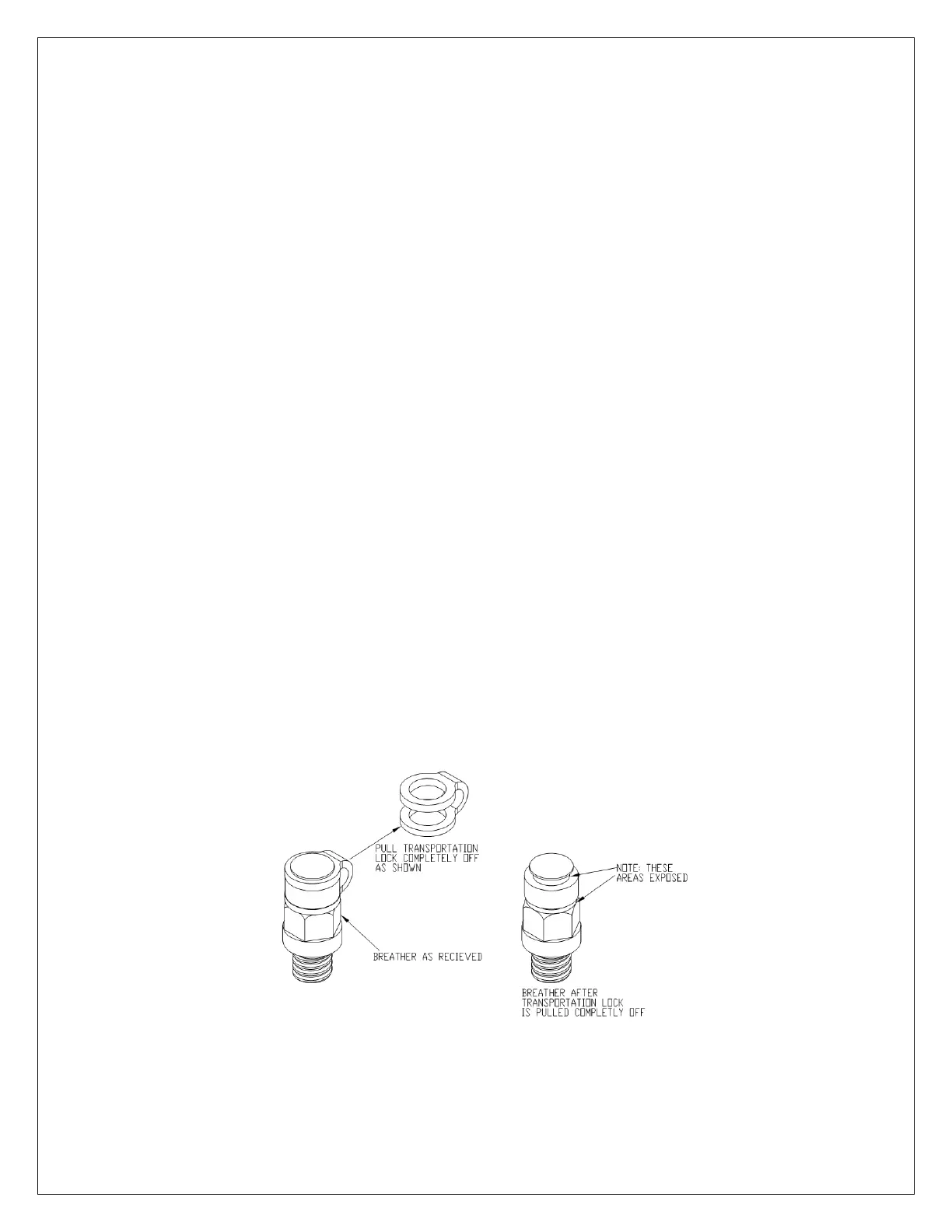

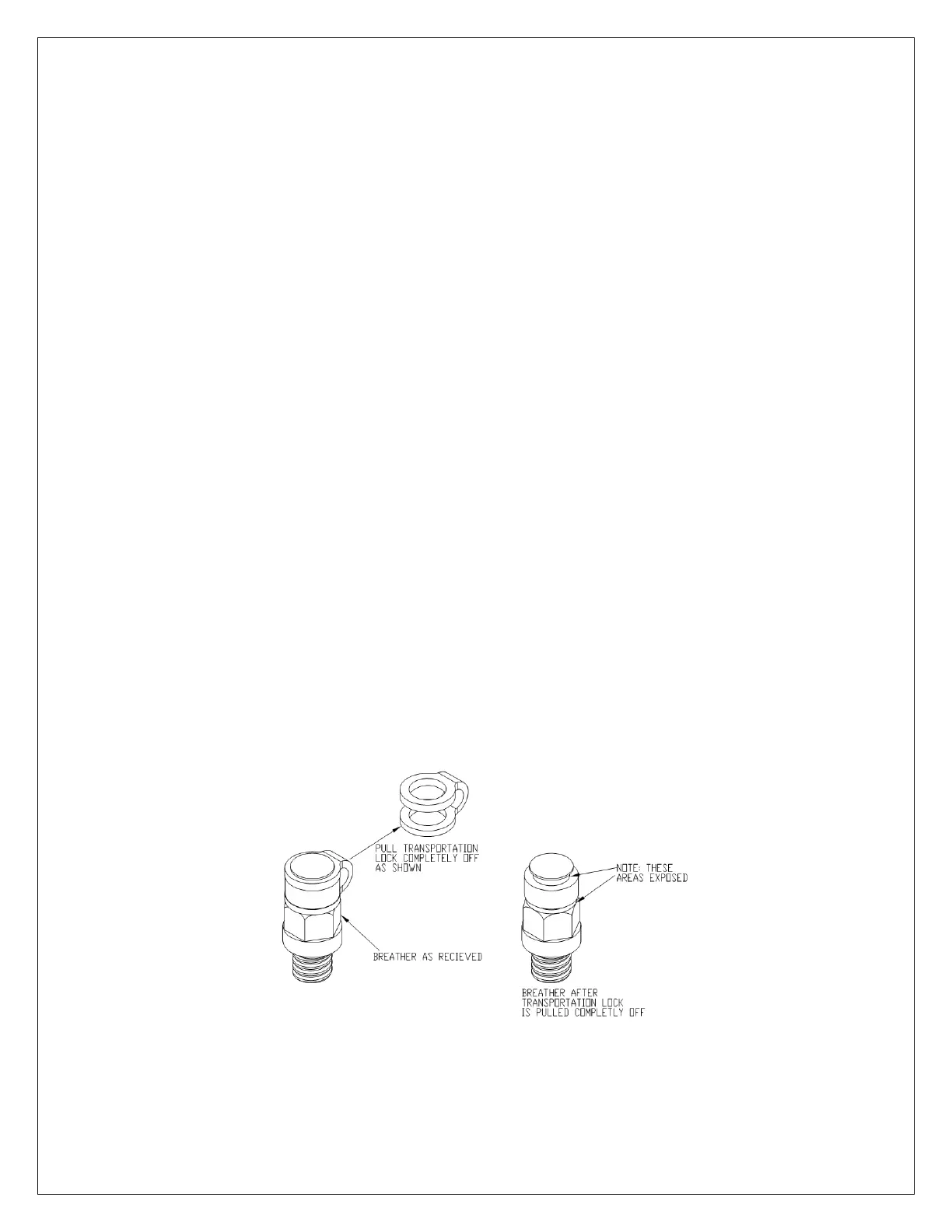

VENT PLUG LOCATION

Washdown and stainless steel units are supplied with a Heinrichs Breather with a rubber

transportation lock. The transportation lock must be completely removed before operation.

Failure to do so may cause the unit to leak. See below.

Before putting the unit into operation, it may be necessary to relocate the vent plug for positions

other than standard (M1). Substitute the vent plug for the solid plug at the position desired.

Install the solid plug in the location the vent plug was removed from. Refer to the following chart

for the recommended vent plug locations based on mounting position.

Loading...

Loading...