5

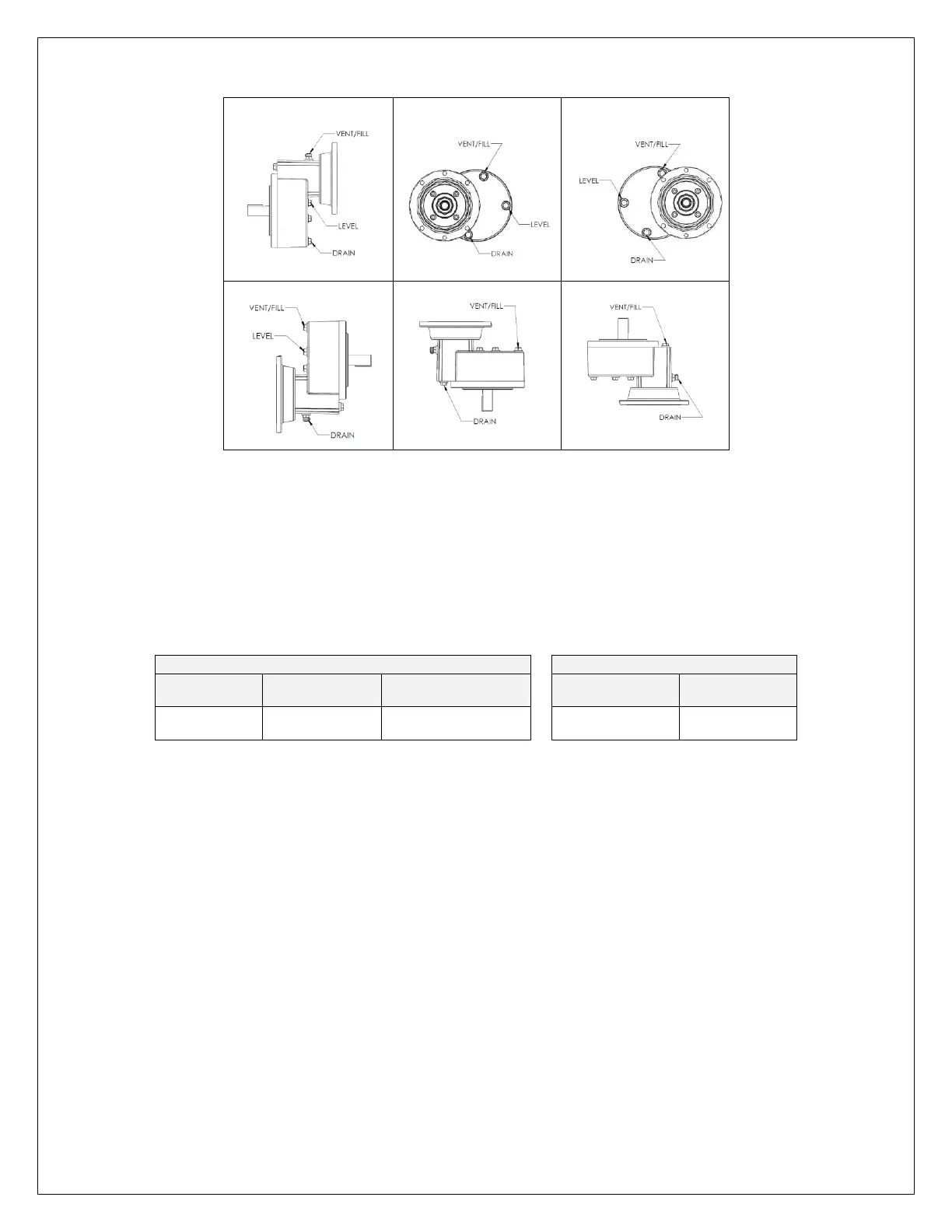

VENT/ LEVEL/ DRAIN LOCATIONS

NOTE: The unit is filled at the factory with the proper amount of oil for the STANDARD

mounting position. The level plug is for reference only so the unit can be checked for

proper oil level prior to installation and start-up. All other mounting positions will require the

oil level to be measured out prior to filling the unit based on the value in the table labeled

OIL CAPACITIES below.

CAUTION: On ALL quill style input units, cast iron and stainless with the input

mounted vertical shaft up or input under will require a double input seal

arrangement to prevent leakage or C-face coupled style units should be

used. Consult factory

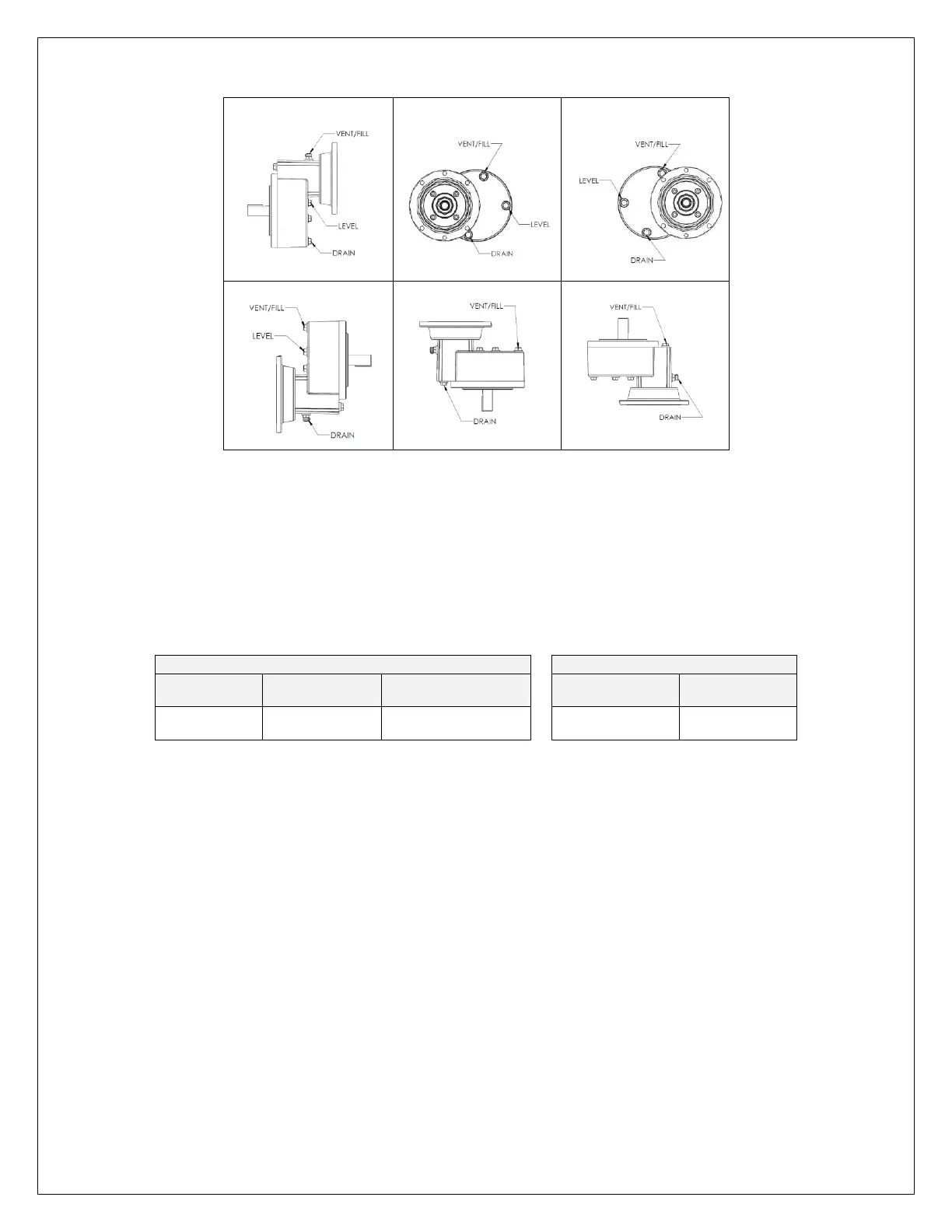

OIL & WEIGHT SPECIFICATIONS

RECOMMENDED LUBRICATION OIL (ISO 150)

OIL CAPACITIES (FLUID OUNCE)

PAO† Synthetic H1

Food Grade

†The use of PAG synthetics is not recommended.

Change Intervals: Standard compounded lubricants should be changed every six months or

2500 operating hours, whichever comes first. Synthetic lubricants should be changed every two

years or 6000 hours, whichever comes first.

CAUTION: Oil should be changed more often if the unit is used in a severe

environment. (i.e. dusty, humid)

CAUTION: In the Food and Drug Industry (including animal food), consult the

lubrication supplier for recommendation of lubricants which are

acceptable to the Food and Drug Administration and/or other authoritative

bodies having jurisdiction.

Loading...

Loading...