MS 461 R

English

43

Different quantities of oil are required for

different bar lengths, types of wood and

cutting techniques.

N Use the adjusting screw (1) (on

underside of machine) to vary the oil

feed rate as required.

N Ematic position (E), medium oil feed

rate – turn the adjusting screw to "E"

(Ematic position).

N Turn the adjusting screw clockwise

to increase oil feed rate.

N Turn the adjusting screw

counterclockwise to reduce oil feed

rate.

When using as rescue saw:

N Turn the adjusting screw (on

underside of machine) clockwise as

far as stop to obtain maximum oil

feed rate.

NOTICE

Your chain must always be wetted with a

film of lubricant.

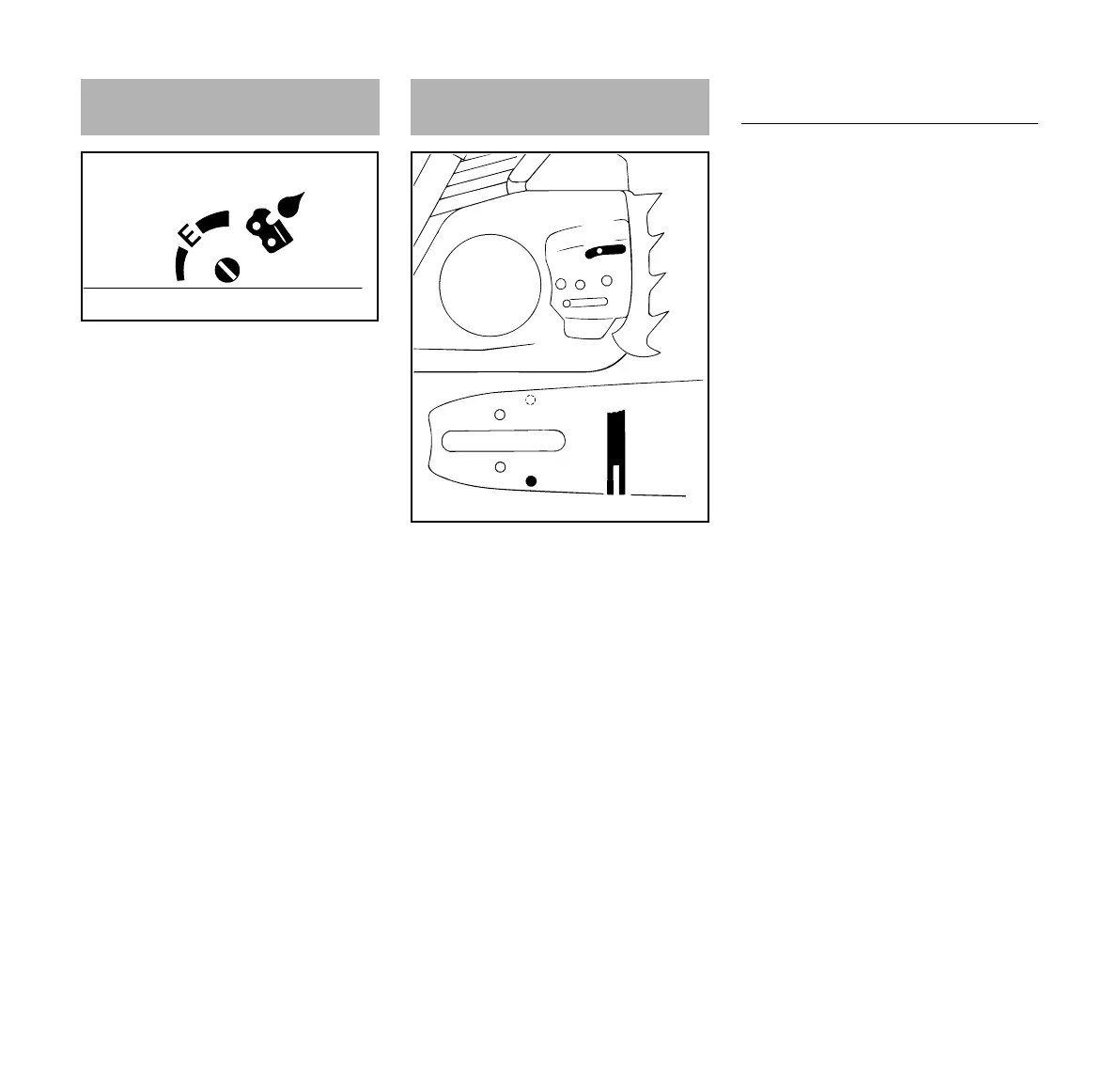

N Turn the guide bar over – every time

you sharpen the chain and every

time you replace the chain – this

helps avoid one-sided wear,

especially at the nose and

underside of the bar.

N Regularly clean the oil inlet hole (1),

the oilway (2) and the bar groove

(3).

N Measure the groove depth – with the

scale on the filing gauge (special

accessory) – in the area used most

for cutting.

If groove depth is less than specified:

N Replace the guide bar.

The drive link tangs will otherwise

scrape along the bottom of the groove –

the cutters and tie straps will not ride on

the bar rails.

Oil Quantity Control

Taking Care of the Guide Bar

Chain

type

Chain pitch Minimum

groove depth

Picco 1/4" P 0.16" (4.0 mm)

Rapid 1/4" 0.16" (4.0 mm)

Picco 3/8" P 0.20" (5.0 mm)

Rapid 3/8"; 0.325" 0.24" (6.0 mm)

Rapid 0.404" 0.28" (7.0 mm)

Loading...

Loading...